Method for preparing electro-spun yarns with polyaniline shell layers

A technology of polyaniline and electrospinning, applied in the direction of conjugated synthetic polymer artificial filament, chemical post-treatment of synthetic polymer artificial filament, textiles and papermaking, etc., can solve the problem of reducing the conductivity of polyaniline and other chemical properties, The problems of low solubility and low molecular weight of polyaniline can achieve the effect of strong ion exchange capacity, improved spinnability and large adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

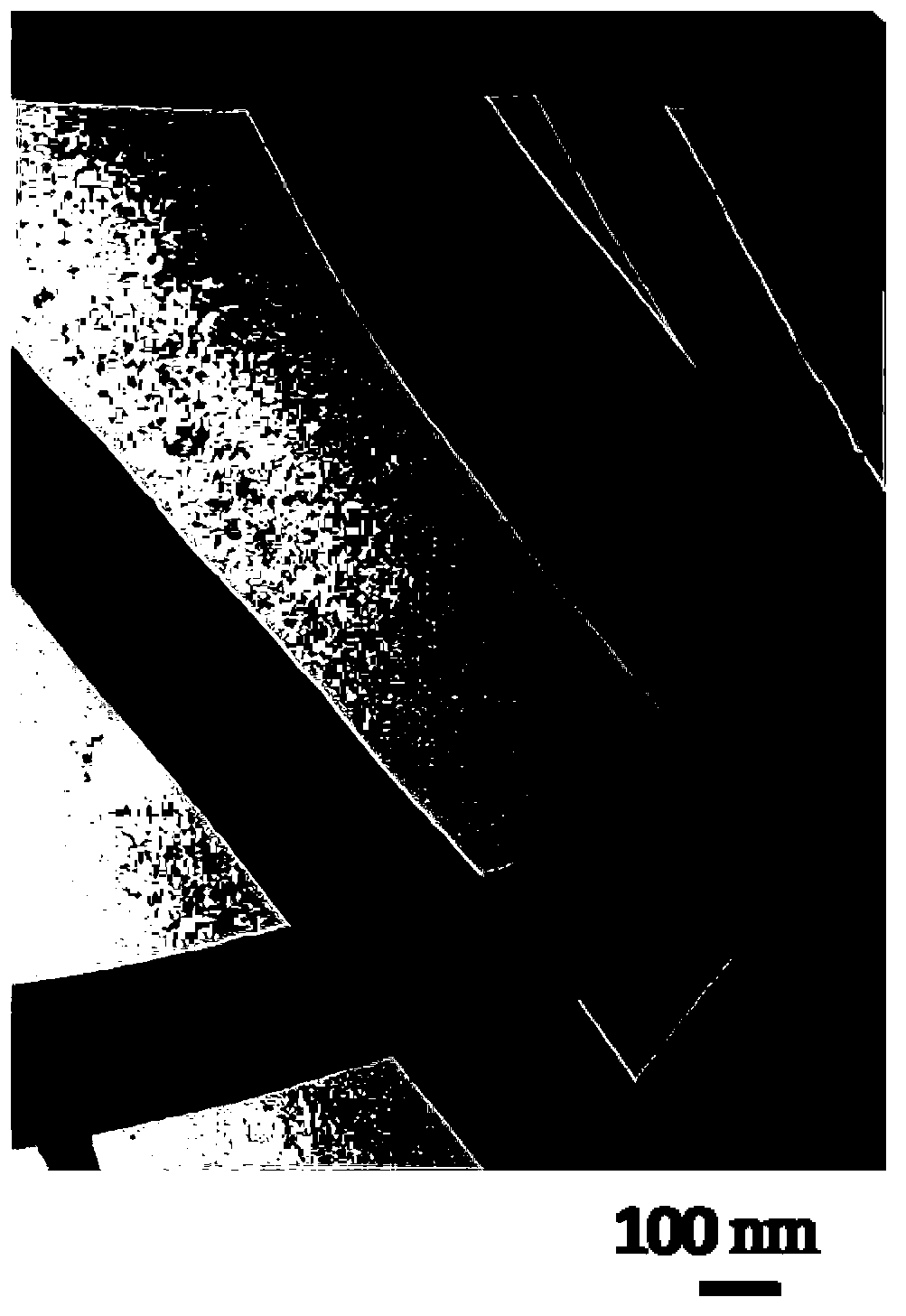

[0034] Example 1 Collagen is used as a water-soluble polymer mixed with polyaniline to produce a core-shell structure electrospinning with polyaniline as the shell and polystyrene as the core

[0035] 1) Configuration of polymer solution: The polymer solution of the core layer is a final concentration of 5% (w / v, g / ml) polystyrene dissolved in a mixed solution of chloroform-hexafluoroisopropanol (v:v=7:3) (A solution), the shell polymer solution is a final concentration of 4% (w / v, g / ml) collagen and a final concentration of 1% (w / v, g / ml) polyaniline doped with camphorsulfonic acid (doped The hetero ratio is the molar ratio of polymer unit to protic acid 1:1) dissolved in hexafluoroisopropanol (B solution).

[0036]2) Construction of the electrospinning device: the electrospinning nozzle is a coaxial structure, the outer pipe is pumped into solution B, and the inner shaft pipe is pumped into solution A. Lay an aluminum foil directly below the nozzle as a receiving pole, and ...

Embodiment 2

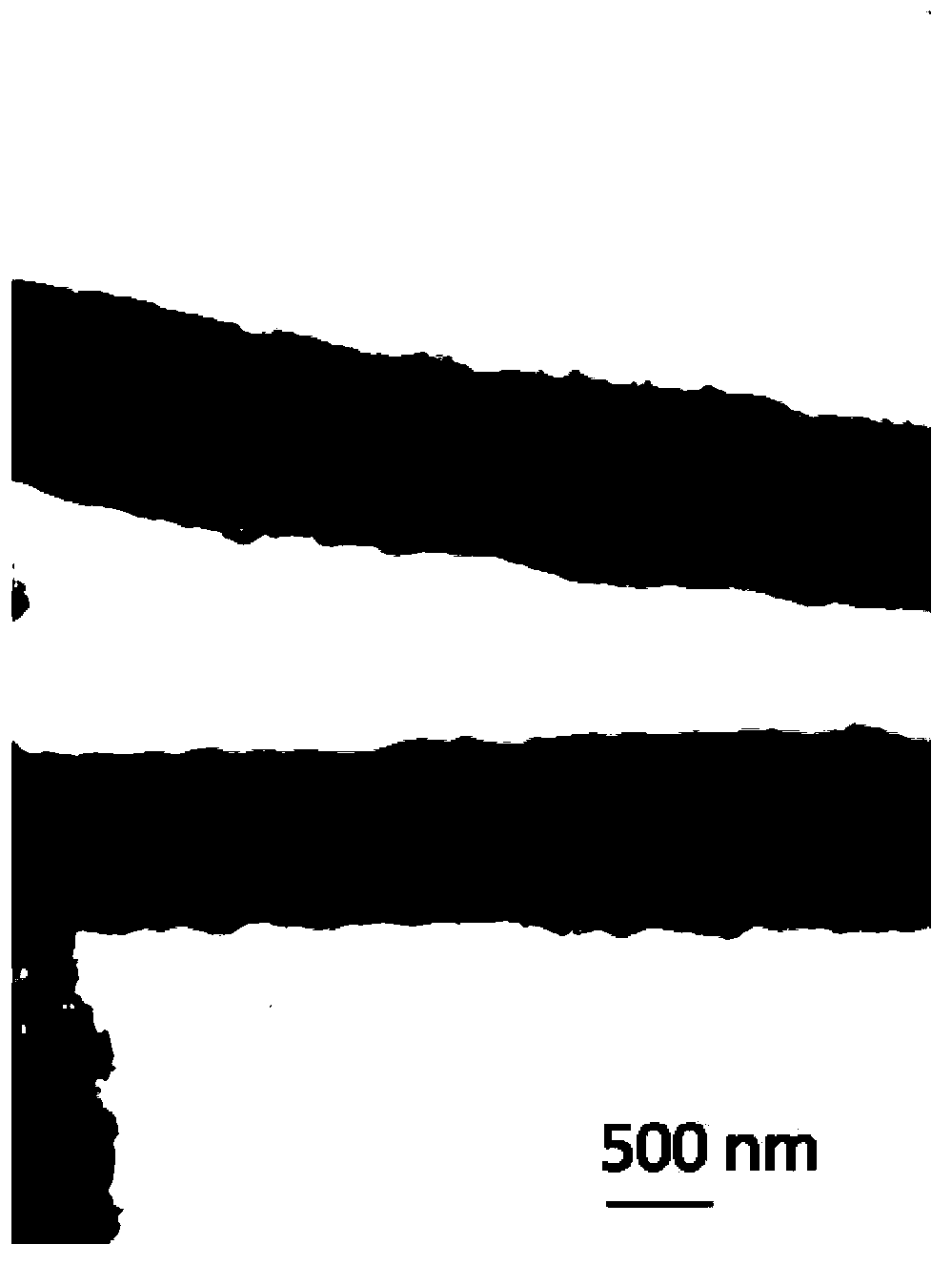

[0040] Example 2 Using polyethylene glycol as a water-soluble polymer mixed with polyaniline to produce core-shell structure electrospinning with polyaniline as the shell and polymethacrylate as the core

[0041] 1) Configuration of polymer solution: The core layer polymer solution is a mixed solution of 30% (w / v, g / ml) polymethacrylate dissolved in chloroform and N,N-dimethylformamide (v / v =6 / 4) mixed solution (A solution), the shell polymer solution is 4% (w / v, g / ml) polyethylene glycol and 2% intrinsic polyaniline (w / v, g / ml) solution A mixed solution of chloroform and N,N-dimethylformamide (v / v=6 / 4) (B solution).

[0042] 2) Construction of the electrospinning device: same as in Example 1

[0043] 3) Electrospinning process: pump liquid A into the inner layer of the coaxial nozzle at a speed of 0.5mL / min, and pump liquid B into the gap between the outer layer and the inner pipe of the coaxial nozzle at a speed of 0.4mL / min. After the flow rate is stable, 20000V DC high v...

Embodiment 3

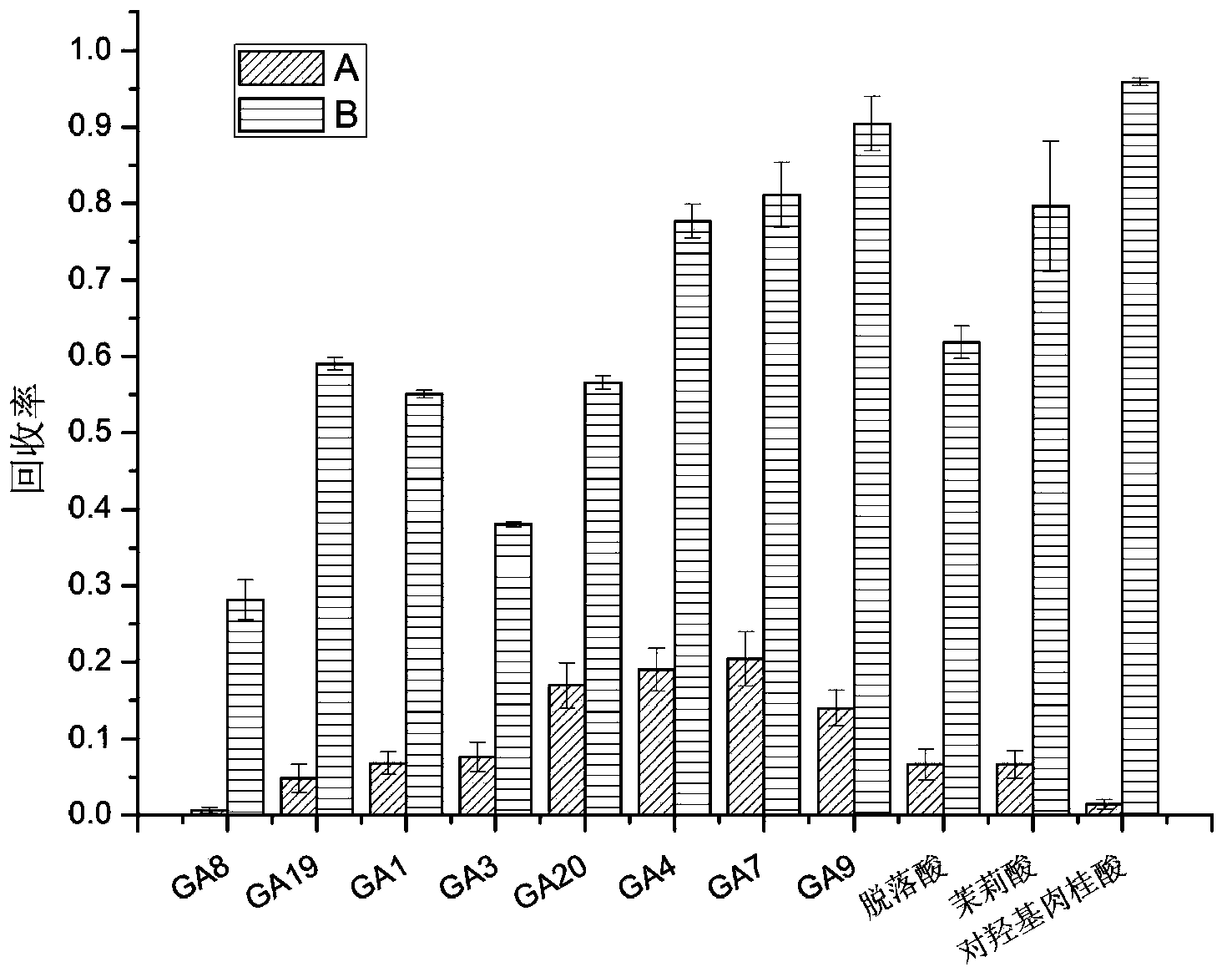

[0045] Example 3 Comparison of electrospinning with polyaniline as the shell and polystyrene as the core layer, and electrospinning with ordinary polyaniline and polystyrene mixed and co-spun, and the extraction efficiency of acid compounds

[0046] 1) Electrospinning preparation of polyaniline as the shell layer: the preparation method is the same as in Example 1. The electrospinning soaking solution in the operation step (4) is 500 mL of 1% (v / v) formic acid aqueous solution (cosolvent is formic acid), the soaking time is 6 hours, and the soaking solution is changed every 2 hours, and finally in After soaking in 500 mL of distilled water for 1 hour, the resulting film was dried in a vacuum oven for 5 hours.

[0047] 2) Preparation of ordinary polyaniline and polystyrene co-spun electrospinning: refer to the prior art scheme (Synthetic Metals, 2000, 114, 109114), wherein the mass concentration of polyaniline is 2%. The mass concentration of polystyrene is 4%, the solvent of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com