Silicon carbide foam ceramic/aluminum alloy composite material brake disc and preparation method thereof

A technology of foam ceramics and composite materials, which is applied in the direction of ceramic products, brake parts, mechanical equipment, etc., can solve the problems of short life, poor thermal conductivity, poor thermal fatigue resistance, etc., and achieve improved service life, good thermal conductivity, and improved Effect of Thermal Fatigue Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

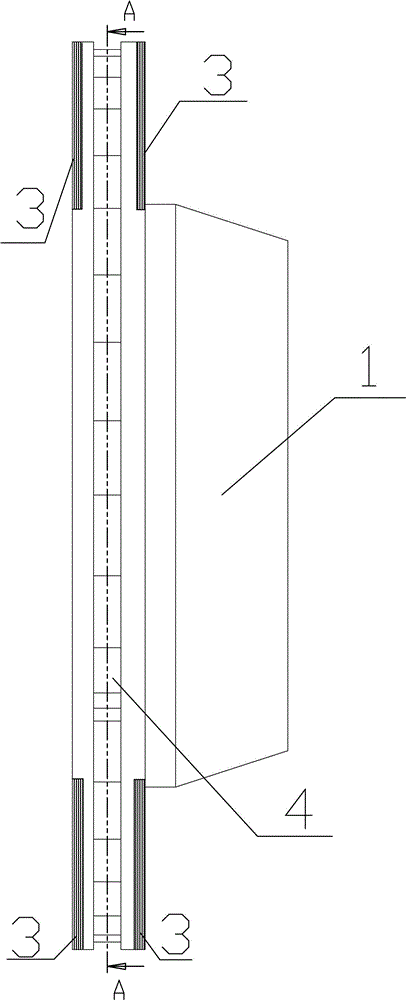

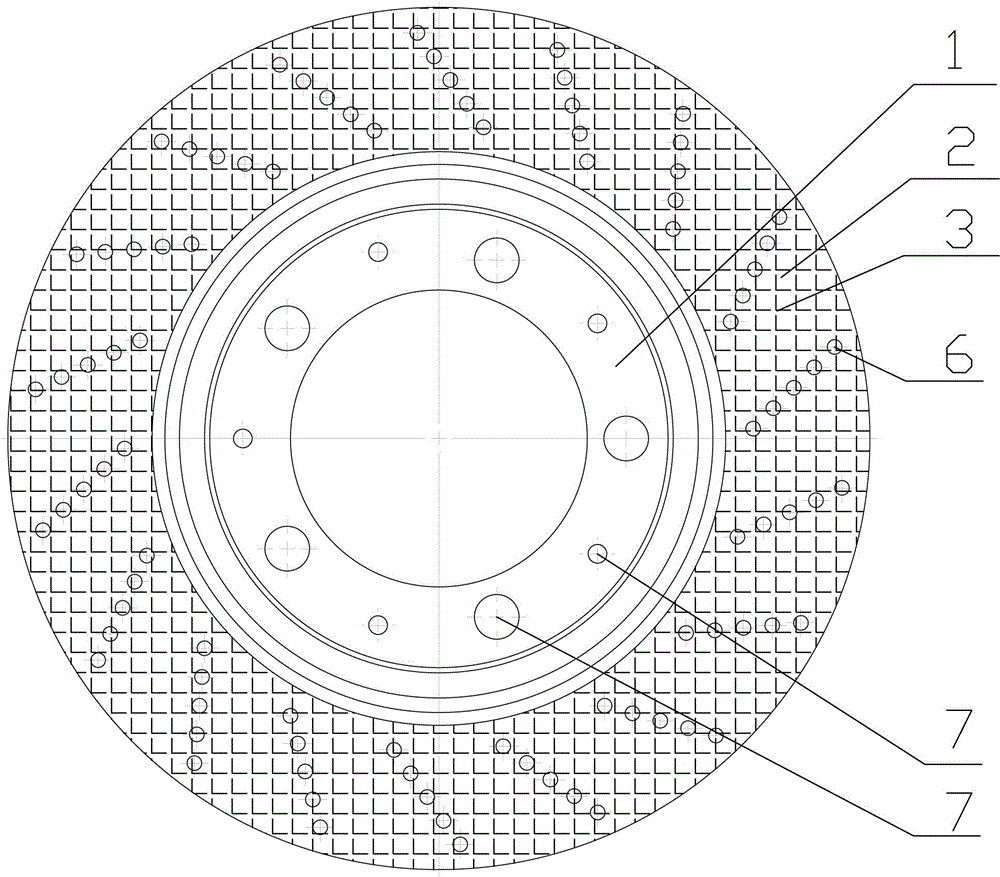

[0081] Silicon carbide foam ceramic skeleton reinforced ZL111 aluminum matrix composite brake disc

[0082] Step 1: Preparation of silicon carbide foam ceramic skeleton: using precursor dipping method to prepare silicon carbide slurry according to a certain proportion, using 8-15ppi polyurethane foam precursor as template, prepare silicon carbide ceramic green body and dry it . Put the silicon carbide ceramic green body into a sintering furnace at 1950~2280℃ for 0.5~3h, pressureless sintering to obtain a silicon carbide foam ceramic block with a length of 400 mm, a width of 400 mm, and a thickness of 5-15 mm. Cut it into the required shape (see attached figure 2 ) As a reinforcement of the friction layer. The porosity of the silicon carbide foam ceramic is 40~60%, the mesh diameter is 1.5~4 mm, the mass percentage of silicon carbide in the silicon carbide foam ceramic framework is 90~99%, and the rest is boron carbide and carbon. The volume density of the ceramic skeleton is 2...

Embodiment 2

[0091] Silicon carbide foam ceramic skeleton reinforced 7075 aluminum matrix composite brake disc

[0092] Step 1: Preparation of the silicon carbide foam ceramic skeleton: using a gel-injection molding method, the slurry prepared in a certain proportion is prepared into a ceramic green body and dried. Using a pressureless sintering method with a sintering temperature of 2000-2250 ℃ and a heat preservation time of 1 to 3 hours, a silicon carbide foam ceramic block with a length of 300 mm, a width of 300 mm and a thickness of 5-7 mm is obtained, which is cut into the required reinforcement by laser shape. The porosity of the silicon carbide foam ceramic is 65%, the mesh diameter is 3~6 mm, the mass percentage of silicon carbide in the silicon carbide foam ceramic is 96~99%, and the density of the ceramic skeleton is 2.6~2.8 g / cm 3 , Vickers hardness (Hv) 18 GPa, flexural strength 10 MPa, compressive strength 5 MPa, thermal conductivity 130 W / (m•K).

[0093] Step 2: Pretreatment of ...

Embodiment 3

[0101] Silicon carbide foam ceramic skeleton reinforced 5083 aluminum-based composite brake disc

[0102] Step 1: Preparation of the silicon carbide foam ceramic skeleton: using a three-dimensional printing method to prepare a certain proportion of the slurry into a ceramic green body for drying and trimming. Using the pressureless sintering method, the sintering temperature is 2200 ℃, and the holding time is 3 hours, a silicon carbide foam ceramic block with a length of 300 mm, a width of 300 mm and a thickness of 25 mm is obtained, which is cut into the required reinforcement shape by laser. The porosity of the silicon carbide foam ceramic is about 60~70%, the mesh diameter is 2~5 mm, the mass percentage of silicon carbide in the silicon carbide foam ceramic is 97%, and the density of the ceramic skeleton is 2.9g / cm 3 , Vickers hardness (Hv) 20GPa, flexural strength 8-10MPa, compressive strength 45-50 MPa, thermal conductivity 120-130 W / (m•K).

[0103] Step 2: Pretreatment of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com