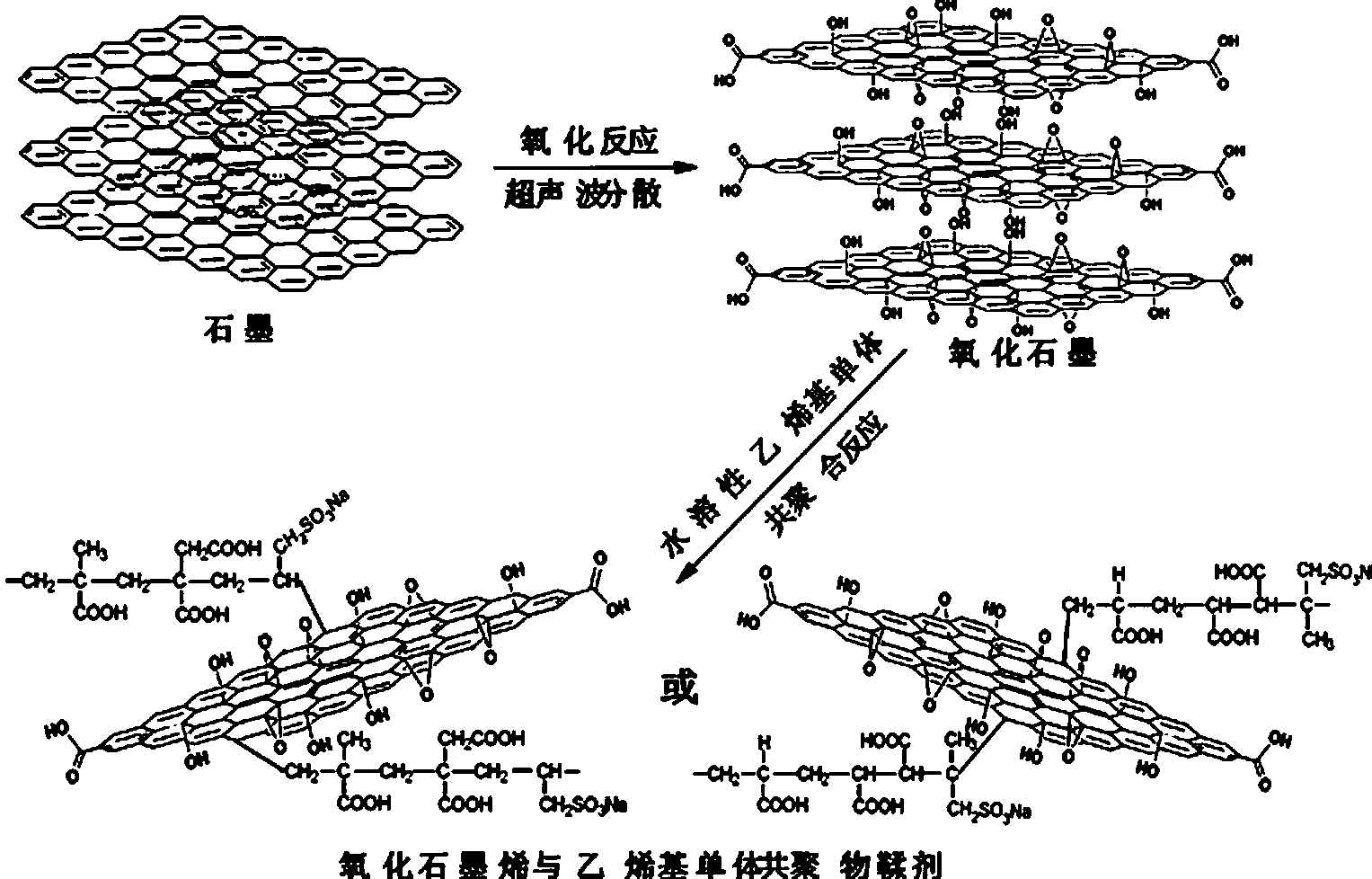

Oxidized graphene and water-soluble vinyl monomer copolymerized leather tanning agent and preparation method thereof

A vinyl monomer and copolymer technology, which is applied in the field of graphene oxide and water-soluble vinyl monomer copolymer leather tanning agent and its preparation, can solve the problem that the chemical effect of the tanning agent and the leather fiber cannot reach the main tanning agent. requirements, can not be used as the main tanning agent and other problems, to achieve the effect of less residual, soft hand feeling, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

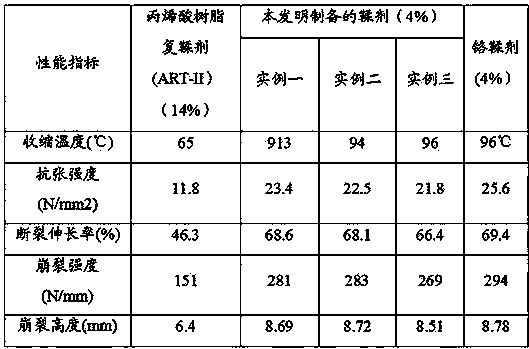

Examples

Embodiment 1

[0034] Step 1: preparation of graphene oxide.

[0035] Slowly add 1 part of graphite powder to a mixture of 40 parts by mass of 98% concentrated sulfuric acid and 3 parts by mass of 85% concentrated phosphoric acid, control the temperature of the system at 5°C, and slowly Add 5 parts of potassium permanganate, react at this temperature for 3 hours, then raise the temperature to 35°C and continue the reaction for 1 hour, then slowly add 150 parts of deionized water, raise the temperature to 90°C and react for 4 hours; then cool down to 50°C Add 20 parts by mass of 30% hydrogen peroxide solution dropwise, react for 30 minutes, then lower the temperature to centrifuge the product, wash it with deionized water until the pH of the washing water is 6.0, and disperse it with ultrasonic waves for 1 hour to obtain Graphene oxide nanosheet dispersion liquid, and control the mass fraction of graphene oxide at about 4%, the thickness of graphene oxide nanosheets is 8~15nm, and the length ...

Embodiment 2

[0043] Step 1: preparation of graphene oxide.

[0044] Slowly add 1 part of graphite powder to a mixture of 40 parts by mass of 98% concentrated sulfuric acid and 3 parts by mass of 85% concentrated phosphoric acid, control the temperature of the system at 5°C, and slowly Add 5 parts of potassium permanganate, react at this temperature for 3 hours, then raise the temperature to 35°C and continue the reaction for 1 hour, then slowly add 150 parts of deionized water, raise the temperature to 90°C and react for 4 hours; then cool down to 50°C Add 20 parts by mass of 30% hydrogen peroxide solution dropwise, react for 30 minutes, then lower the temperature to centrifuge the product, wash it with deionized water until the pH of the washing water is 6.0, and disperse it with ultrasonic waves for 1 hour to obtain oxidation. Graphene nanosheet dispersion liquid, and control the mass fraction of graphene oxide at about 4%, the thickness of graphene oxide nanosheets is controlled to be 8...

Embodiment 3

[0052] Step 1: preparation of graphene oxide.

[0053] Slowly add 1 part of graphite powder to a mixture of 40 parts by mass of 98% concentrated sulfuric acid and 3 parts by mass of 85% concentrated phosphoric acid, control the temperature of the system at 5°C, and slowly Add 5 parts of potassium permanganate, react at this temperature for 3 hours, then raise the temperature to 35°C and continue the reaction for 1 hour, then slowly add 150 parts of deionized water, raise the temperature to 90°C and react for 4 hours; then cool down to 50°C Add 20 parts by mass of 30% hydrogen peroxide solution dropwise, react for 30 minutes, then cool down and centrifuge the product, wash it with deionized water until the pH of the washing water is 6.0, and disperse it with ultrasonic waves for 1 hour Obtain the graphene oxide nanosheet dispersion liquid, and control the mass fraction of graphene oxide at about 4%, control the thickness of the graphene oxide nanosheet layer to be 8~15nm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com