Adhesive, adhesive sheet and displayer

An adhesive and copolymer-like technology, which is applied in the field of adhesive sheets and displays, can solve the problems of gas generation, poor flexibility, hard material, etc., and achieve excellent foam resistance, excellent peel resistance, and not easy to whiten Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] Hereinafter, the present invention will be further specifically described in conjunction with examples, but the present invention is not limited by these examples. In addition, in the following examples, "parts by weight" are represented by "parts", and "% by weight" are represented by "%".

Synthetic example 1

[0102] Using a reaction device with a stirrer, a reflux cooling pipe, a nitrogen conduit, a thermometer, and a dropper, 50% by weight of the total amount of each monomer in Table 3, an appropriate amount of azobisisobutyronitrile as an initiator, and acetic acid as a solvent Ethyl ester was added to the reaction tank. Subsequently, all the remaining monomers, and an appropriate amount of ethyl acetate and azobisisobutyronitrile and mixed solution were added dropwise into the reaction tank for about 2 hours from a dropper, and then in a nitrogen environment, Polymerization was carried out at about 80°C for 5 hours. After the reaction was completed, it was cooled and diluted with ethyl acetate to obtain a copolymer solution with a non-volatile content of 40% and a viscosity of 3000 mPa·s. Here, the obtained copolymer is referred to as copolymer (A-1).

Synthetic example 2~36

[0104] Various raw materials were added according to the weight ratios in Table 3 and Table 4, and the acrylic acid copolymer was synthesized by the same method as in Synthesis Example 1. And the weight average molecular weight of the obtained acrylic copolymer is shown in Table 3 and Table 4.

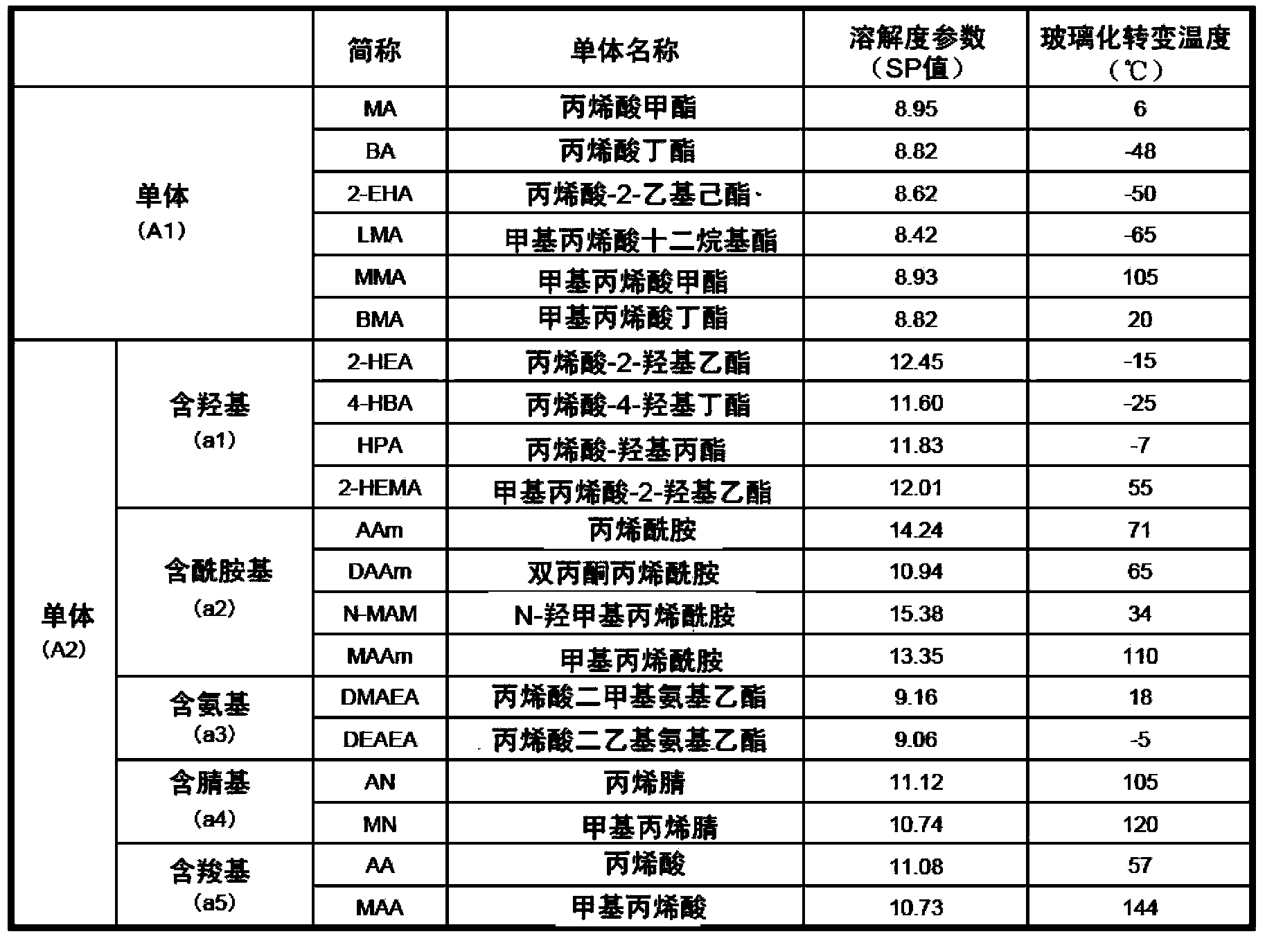

[0105] [table 3]

[0106]

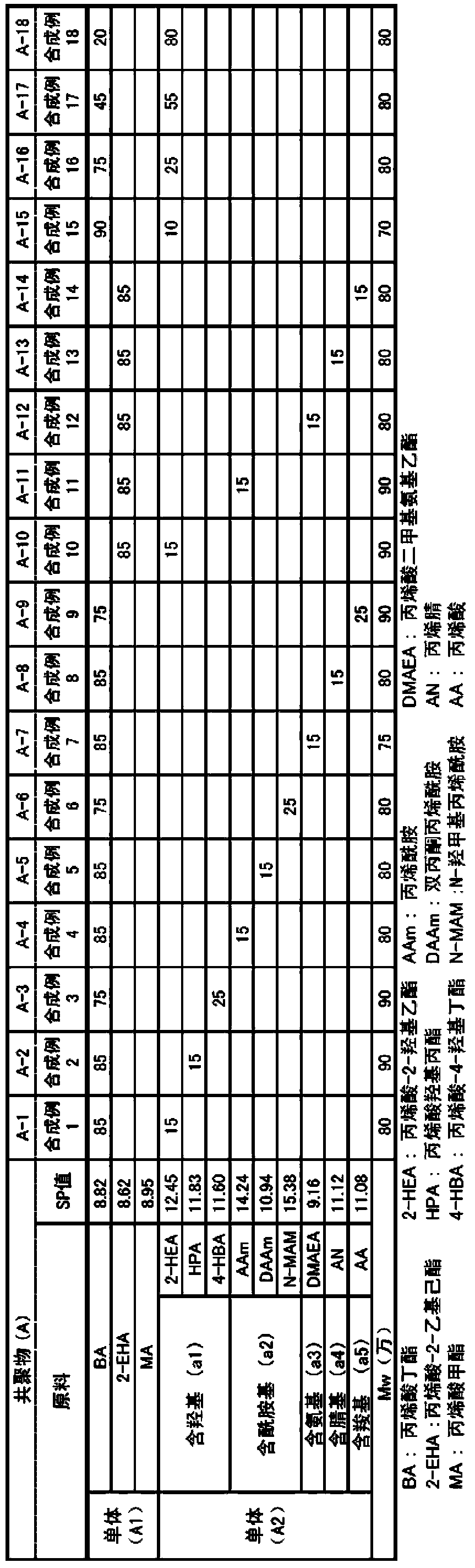

[0107] [Table 4]

[0108]

[0109]

[0110] The measurement of the weight average molecular weight used GPC "LC-GPC system" manufactured by Shimadzu Corporation. GPC is liquid chromatography that separates and quantifies substances dissolved in a solvent (THF:tetrahydrofuran) according to the difference in molecular size, and determines the weight average molecular weight in terms of polystyrene.

[0111] Device name: LC-GPC system "Prominence" manufactured by Shimadzu Corporation

[0112] Column: 4 GMHXL manufactured by Tosoh Corporation and 1 HXL-H manufactured by Tosoh Corporation were connected in series.

[0113] Mobile phase solvent: tetrah...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com