Method for coating high-temperature corrosion and wear resistant coating layer on surface of steel material

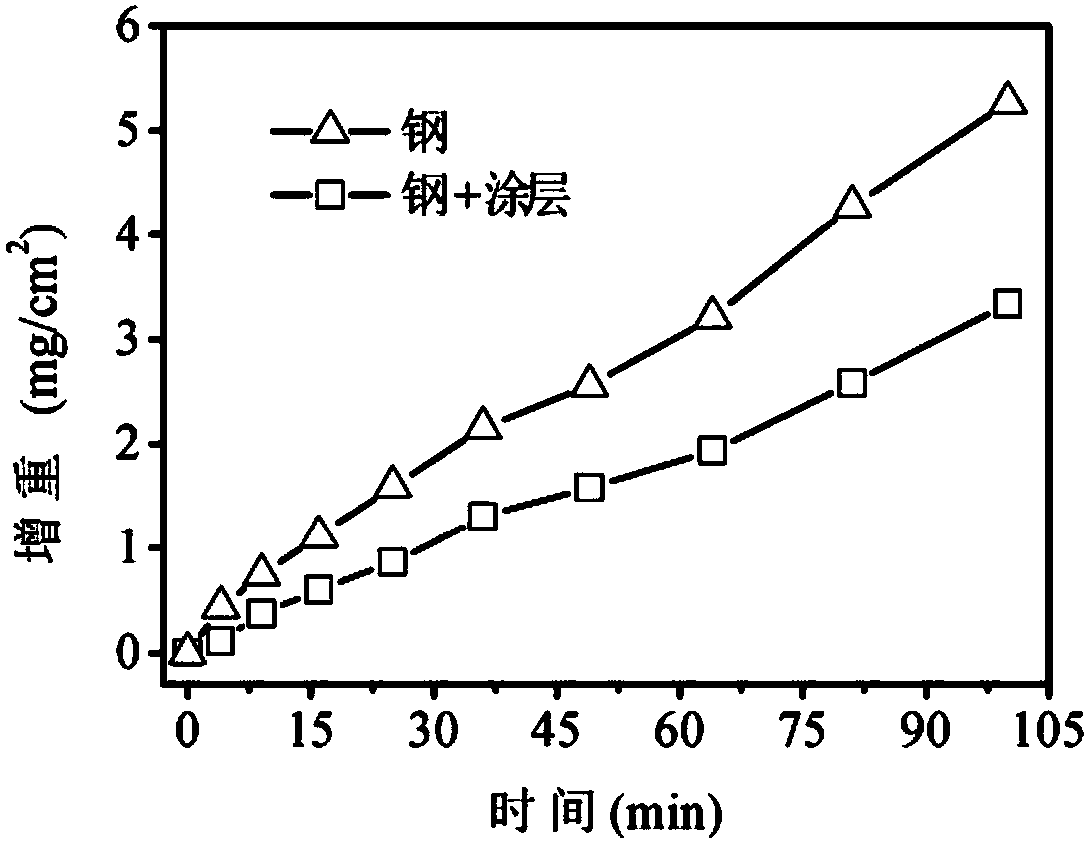

A surface coating and wear-resistant coating technology, applied in metal material coating process, coating, fusion spraying and other directions, can solve the problems of high cost, poor toughness, limited effect, etc., and achieve good adhesion and good bonding Strength, the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

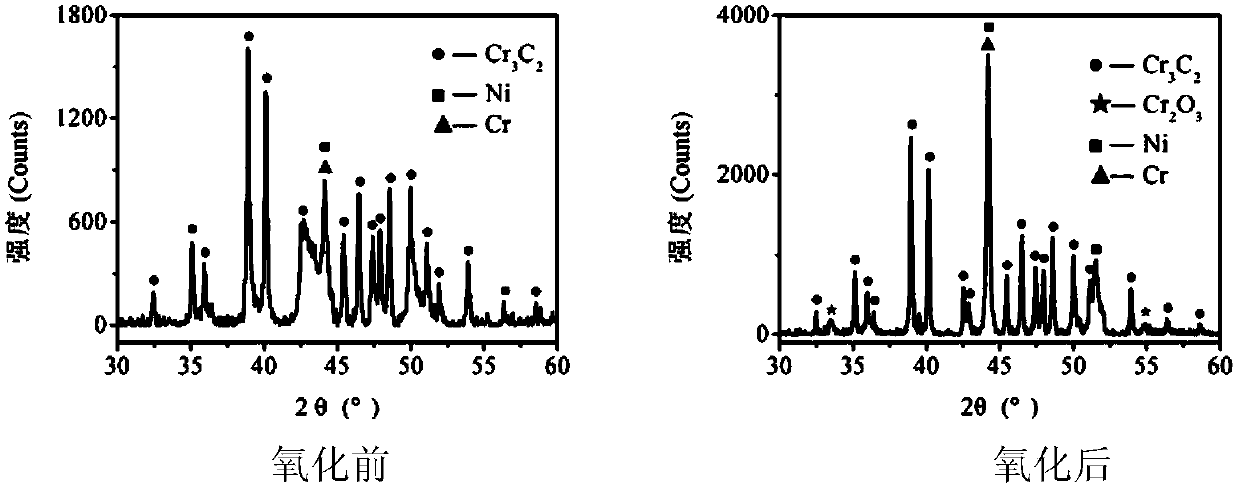

Method used

Image

Examples

Embodiment 1

[0040] The first step: choose 200mm×200mm×2mm Q235 steel plate as the base material, clean the surface to be sprayed, use grinding or milling to remove rust spots and sundries, and use acetone to remove surface grease.

[0041] Step 2: Use a sandblasting machine to perform sandblasting on the cleaned surface. The sand is 30 mesh alumina, and then remove the remaining sand on the surface.

[0042] Step 3: Fix the sandblasted steel plate on the fixture. Before spraying, move the spray gun to preheat the surface of the steel plate. The preheating temperature is 200°C. The Cr2C3-25Ni20Cr powder material is sprayed onto the surface of the steel plate to be protected by the method of high-speed flame spraying, and the particle size of the powder is 45 mesh. The control range of spraying process parameters is as follows;

[0043] 1) Oxygen flow: 800 L / min;

[0044] 2) Carrier gas flow: 2×8L / min;

[0045] 3) Fuel flow: 20 L / h;

[0046] 4) The combustion chamber pressure is: 0.8MPa...

Embodiment 2

[0051] The first step: choose the diameter The 316 round steel rod is used as the base material, and the surface to be sprayed is cleaned by grinding and turning to remove rust spots and debris, and the surface grease is removed with acetone.

[0052] Step 2: Use a sandblasting machine to perform sandblasting on the cleaned surface. The sand is 30 mesh alumina, and then remove the remaining sand on the surface.

[0053] Step 3: Fix the sandblasted round steel on a specific fixture. Before spraying, rotate the round steel and move the spray gun to preheat the surface of the round steel. The preheating temperature is 200°C. The Cr2C3-50Ni20Cr powder material is sprayed onto the surface of the round steel by the method of high-speed flame spraying, and the particle size of the powder is 45 mesh. The control range of spraying process parameters is as follows;

[0054] 1) Oxygen flow: 800 L / min;

[0055]2) Carrier gas flow: 2×8L / min;

[0056] 3) Fuel flow: 20 L / h;

[0057] 4)...

Embodiment 3

[0063] The first step: choose 200mm×200mm×2mm Q235 steel plate as the base material, clean the surface to be sprayed, use grinding or milling to remove rust spots and sundries, and use acetone to remove surface grease.

[0064] Step 2: Use a sandblasting machine to perform sandblasting on the cleaned surface. The sand is 30 mesh alumina, and then remove the remaining sand on the surface.

[0065] Step 3: Fix the sandblasted steel plate on a specific fixture. Before spraying, move the spray gun to preheat the surface of the steel plate. The preheating temperature is 200°C. The Cr2C3-25Ni20Cr powder material is sprayed onto the surface of the steel plate to be protected by the method of gas plasma spraying, and the particle size of the powder is 45 mesh. The control range of spraying process parameters is as follows;

[0066] 1) Hydrogen pressure: 12MPa;

[0067] 2) Argon pressure: 13MPa;

[0068] 3) Hydrogen flow: 15L / h;

[0069] 4) Argon gas flow: 80L / h;

[0070] 5) The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com