Preparation method for micro-fine spherical titanium alloy powder

A technology for titanium alloy powder and alloy body is applied in the field of preparation of fine spherical titanium alloy powder, which can solve the problems of coarse powder particle size, low powder fluidity, low oxygen content, and high production cost, and achieve uniform particle size distribution, simple operation, and high production cost. Effects that are easy to automate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the fine spherical titanium alloy powder of the present invention comprises the following steps:

[0019] First, titanium hydride or titanium and at least two alloying elements (alloying elements are preferably Al, V, Fe, Zr, Mo and Nb) are selected for batching. Since titanium hydride or titanium and at least two alloying elements are used as raw materials, the products are titanium alloy powder and water. The raw materials and products are non-toxic and harmless, and will not pollute the environment or damage high-frequency plasma equipment.

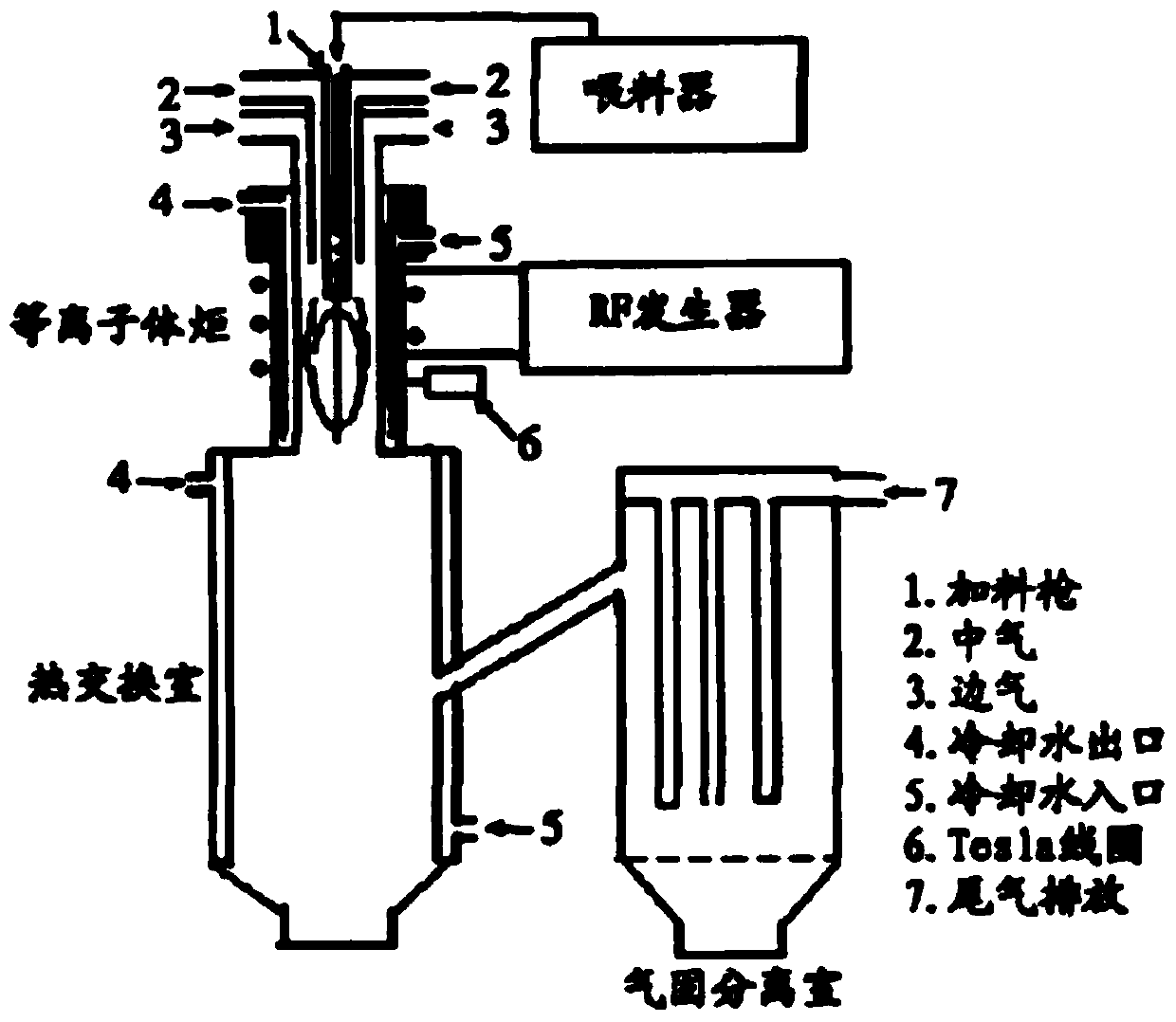

[0020] Then use hydrogen or nitrogen as carrier gas to send the above-mentioned ingredients into a plasma torch for vaporization and melting to form an alloy body. The high-frequency plasma equipment used in this step is as figure 1 As shown, it mainly includes feeder, plasma torch, RF generator (radio frequency generator), heat exchange chamber and gas-solid separation chamber. In this step, the meth...

Embodiment 1

[0024] This embodiment provides a preparation method of fine spherical titanium alloy powder, comprising the following steps:

[0025] (a) Select titanium hydride and Al, Fe, Mo three alloying elements for batching;

[0026] (b) Use nitrogen as the carrier gas to send the ingredients into the plasma torch for vaporization and melting to form an alloy body. The flow rate of the carrier gas is 0.5m 3 / h, the feed rate is 5g / min, and the power of the plasma torch is 50kW, and the flow rate of the generated gas is 1m 3 / h of argon, side gas flow rate 1m 3 / h of nitrogen, the pressure is a negative pressure of 200mm Hg;

[0027] (c) Lead the alloy body into a heat exchange chamber with a temperature of 150°C, and the heat exchange adopts a flow rate of 0.3m 3 / h cooling air;

[0028] (d) Introduce the fine spherical titanium alloy powder into the gas-solid separation chamber to collect the solid powder.

Embodiment 2

[0030] This embodiment provides a preparation method of fine spherical titanium alloy powder, comprising the following steps:

[0031] (a) Select titanium hydride and Fe, Mo, Nb three alloying elements for batching;

[0032] (b) Use nitrogen as the carrier gas to send the ingredients into the plasma torch for vaporization and smelting to form an alloy body. The flow rate of the carrier gas is 5m 3 / h, the feed rate is 100g / min, and the power of the plasma torch is 5kW, and the flow rate of the generated gas is 3m 3 / h of argon, the side gas flow rate is 20m 3 / h of nitrogen, the pressure is a negative pressure of 50mm Hg;

[0033] (c) Lead the alloy body into a heat exchange chamber with a temperature of 150°C, and the heat exchange adopts a flow rate of 0.3m 3 / h cooling air;

[0034] (d) Introduce the fine spherical titanium alloy powder into the gas-solid separation chamber to collect the solid powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com