Environmental energy-saving fire-proofing cooper-aluminum alloy electric cable and manufacturing method thereof

A copper-aluminum alloy, environmental protection and energy-saving technology, which is applied in the direction of cable/conductor manufacturing, insulated cables, metal/alloy conductors, etc., can solve the problems of short-circuit fire, loss, and easy burn-through of wires and cables, achieving less smoke generation, Reduce accidental loss and improve fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

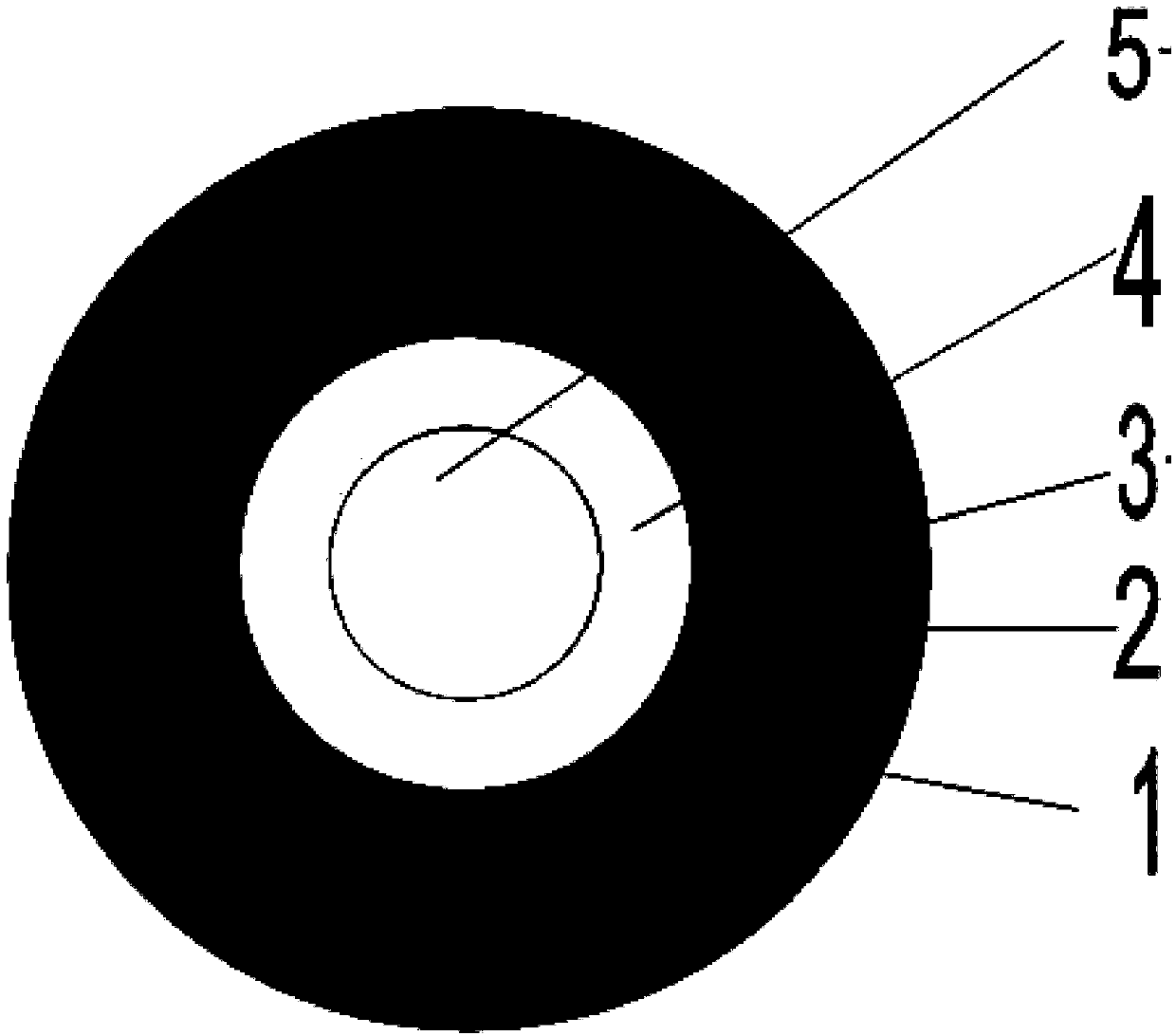

[0014] Such as figure 1 As shown, the copper-clad aluminum alloy fireproof wire and cable of the present invention is composed of an insulating layer of fireproof mica tape 2 coated with a copper-clad aluminum conductive core wire 1, and an additional cross-linked insulating fireproof sheath 3. The conductive core wire shown in the figure 1 is composed of copper 4 coated aluminum core wire 5.

[0015] The fire-proof mica tape 2 and the fire-proof sheath 3 of the insulating layer are made by mixing nano-modified polyolefin polymer, nano-fireproof agent, nano-smoke suppressant and filler. As a preference and improvement, a graphite dielectric layer is also provided between the aluminum core wire layer and the copper layer. The graphite dielectric layer is set, which has strong oxidation resistance and improves electrical conductivity. In order to facilitate the recycling of raw materials and reduce costs, the copper is twisted from at least one pure copper wire, and the alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com