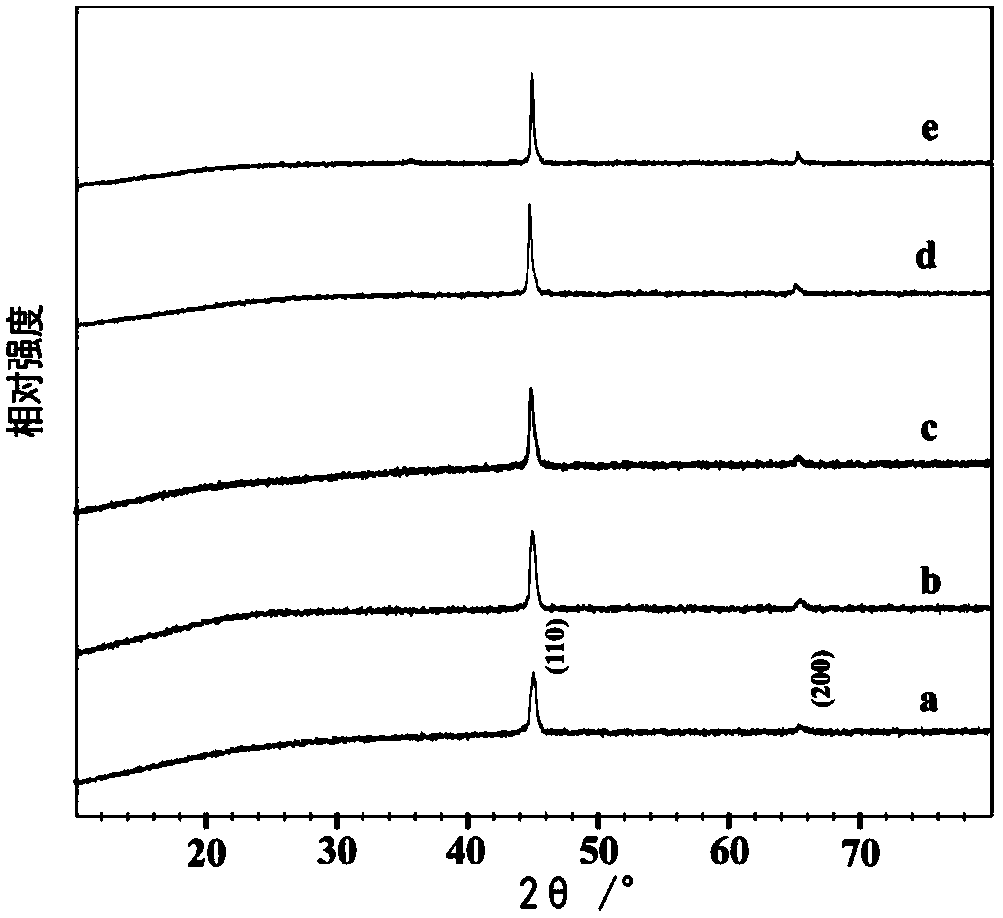

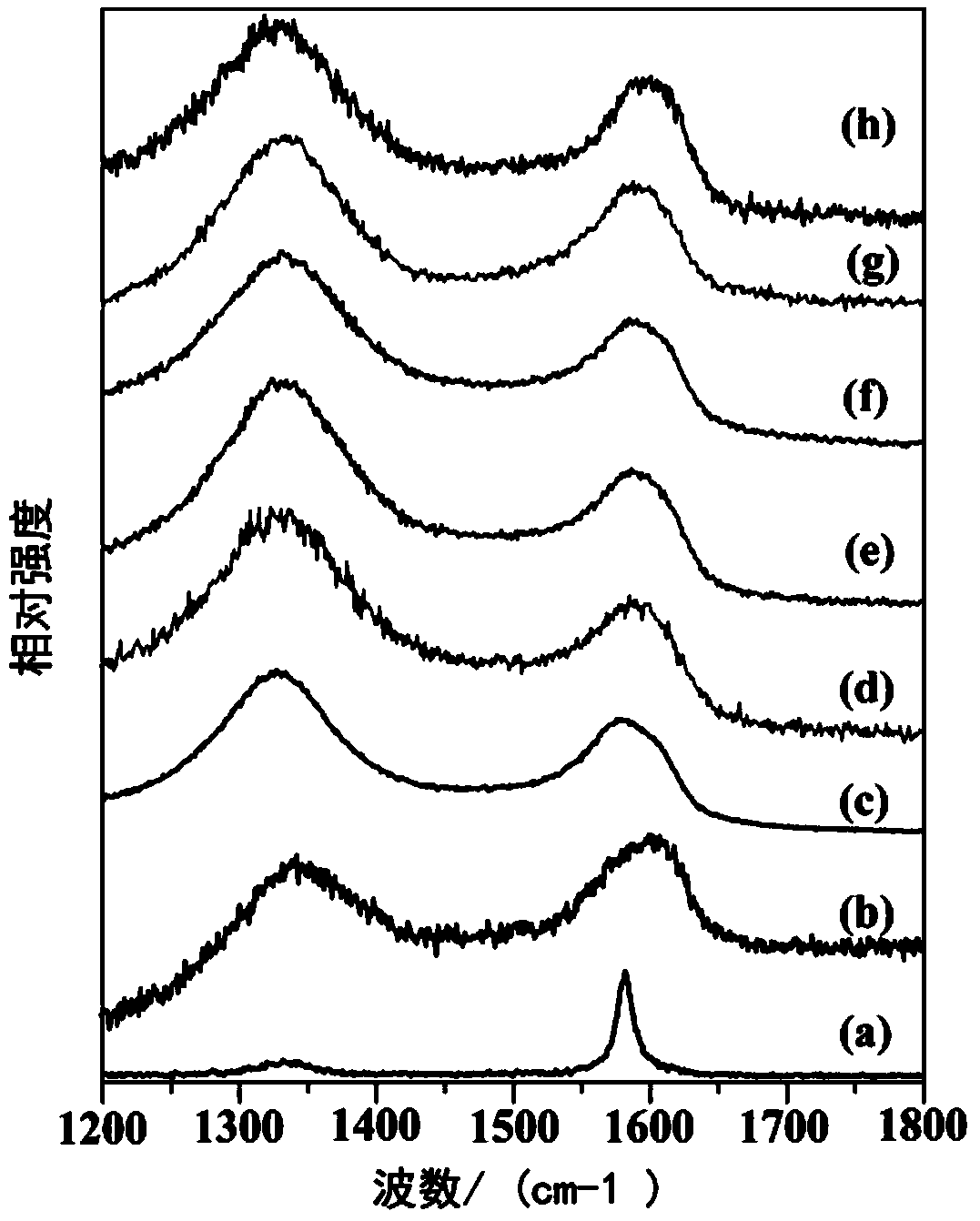

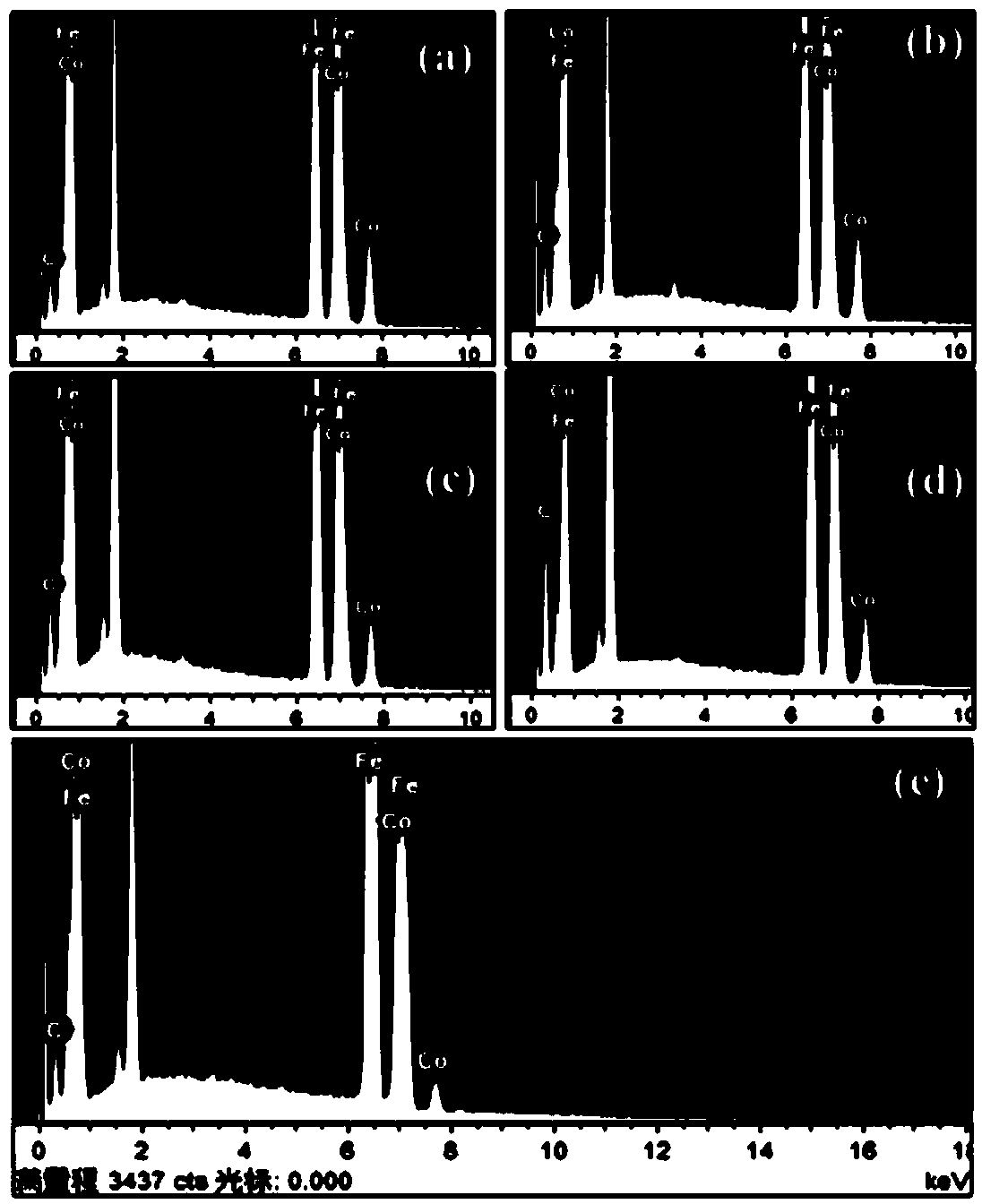

Ferrocobalt nanocrystalline-graphene composite material and preparation method and application thereof

A technology of iron-cobalt alloy and composite materials, which is applied in the field of electromagnetic wave materials, can solve the problems of reducing electromagnetic properties, and achieve the effects of good wave-absorbing performance, cheap and easy-to-obtain raw materials, and good economic prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the above-mentioned iron-cobalt alloy nanocrystal-graphene composite material comprises the following steps:

[0032] a) After mixing graphite oxide and N-methylpyrrolidone, disperse to obtain the first dispersion liquid, wherein the mass ratio of graphite oxide to N-methylpyrrolidone is preferably 0.8 g / L to 1.6 g / L; The method of dispersion is preferably ultrasonic dispersion, vibration dispersion or a combination thereof, more preferably ultrasonic dispersion, and the time of ultrasonic dispersion is not specifically limited in the present invention, as long as the first dispersion liquid that can be uniformly dispersed is obtained.

[0033] b) Iron acetylacetonate, cobalt acetylacetonate, octadecylamine and potassium hydroxide are added to the first dispersion liquid, and continue to disperse to obtain the second dispersion liquid, wherein the quality of graphite oxide is the same as that of iron acetylacetonate, acetylacetonate The ratio o...

Embodiment 1

[0054] Weigh homemade 40mg of graphite oxide and 25ml of N-methylpyrrolidone in a 50ml beaker, ultrasonically disperse for about 2 hours to obtain the first brown dispersion liquid; , a total amount of 3 mmol, was added to the first dispersion, and then 1 g of octadecylamine and 0.5 g of potassium hydroxide were added, and the ultrasonic wave was continued until the dispersion was uniformly mixed to obtain the second dispersion;

[0055] In the fume hood, add 3ml of hydrazine hydrate to the second dispersion liquid, pass through protective gas N 2 After 5 minutes, the oxygen dissolved in the solution was removed to obtain the third dispersion liquid, and then the third dispersion liquid was transferred to a 100 ml polytetrafluoroethylene reactor, and reacted at 160° C. for 1 hour. The reaction product was separated by centrifugation in a high-speed refrigerated centrifuge, then washed alternately with cyclohexane and acetone for 3 times, and then alternately washed with deioni...

Embodiment 2

[0057] Weigh homemade 40mg of graphite oxide and 35ml of N-methylpyrrolidone in a 50ml beaker, ultrasonically disperse for about 2 hours to obtain the first brown dispersion liquid; , a total amount of 5 mmol, was added to the first dispersion, and then 2 g of octadecylamine and 1 g of potassium hydroxide were added, and the ultrasound was continued until the dispersion was uniformly mixed to obtain the second dispersion;

[0058] In the fume hood, add 5ml of hydrazine hydrate to the second dispersion, pass through the protective gas Ar for 5min, and get rid of the dissolved oxygen in the solution to obtain the third dispersion, then transfer the third dispersion to a 100ml polytetrafluoroethylene reactor , reacted at 180°C for 2 hours. The product was separated by centrifugation, washed alternately with n-hexane and acetone for three times, then alternately washed twice with deionized water and ethanol, filtered, and vacuum-dried at 40°C for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com