Ceramic halogen lamp electrode and ceramic halogen lamp

A ceramic metal halide lamp and electrode technology, which is applied in the fields of ceramic metal halide lamp electrodes and ceramic metal halide lamps, can solve problems such as radioactive pollution, and achieve the effects of avoiding radioactive pollution, ensuring low current, and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the above-mentioned luminescent pill comprises the following steps:

[0033] Step S110, sodium iodide (NaI), thallium iodide (TII) and indium iodide (InI 3 ) and the resulting mixture was vacuum treated at 130 °C for 50 min.

[0034] Sodium iodide (NaI), thallium iodide (TII) and indium iodide (InI 3 ) The molar ratio is 0.005~0.015:6.0×10 -4 ~7.0×10 -4 :4.0×10 -5 ~4.7×10 -5 .

[0035] Preferably, the mixture is placed in a quartz container with a nozzle for vacuum treatment.

[0036] Step S120, heating the mixture until melting, and stirring for 30 minutes.

[0037] Step S130, under the atmosphere of protective gas, make the molten mixture into a spherical shape and cool down to obtain a luminous pill.

[0038] Preferably, the protective gas is selected from at least one of argon and nitrogen.

[0039] Preferably, the molten mixture is sprayed through a nozzle to form the molten mixture into a spherical shape.

[0040] Preferably, th...

Embodiment 1

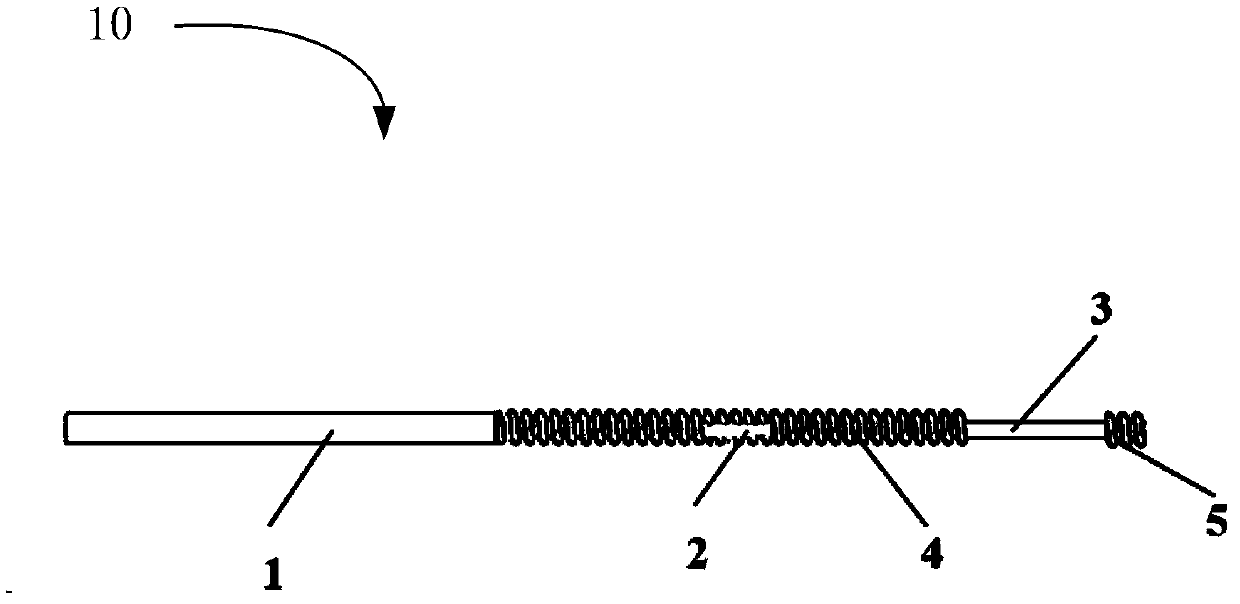

[0050] The ceramic metal halide lamp electrode includes a lead wire 1 , a connecting rod 2 , an electrode rod 3 , a molybdenum wire helix 4 and a tungsten wire helix 5 . One end of the lead wire 1 is connected to one end of the connecting rod 2 . The material of the lead wire 1 is niobium. The lead wire 1 is rod-shaped and coaxial with the connecting rod 2 . In this embodiment, the lead wire 1 is connected to one end of the connecting rod 2 by welding. The material of the connecting rod 2 is niobium. One end of the electrode rod 3 is connected to the end of the connecting rod 2 away from the lead wire 1 . In this embodiment, one end of the electrode rod 3 is connected to one end of the connecting rod 2 by welding. The connecting rod 2 is coaxial with the electrode rod 3 . The material of the electrode rod 3 includes tungsten, hafnium oxide and yttrium oxide. The total mass percentage of hafnium oxide and yttrium oxide in the electrode rod 3 is 0.2%, and the rest is tungst...

Embodiment 2

[0057] The structure of the light-emitting electrode of the ceramic metal halide lamp in Example 2 is roughly the same as that of the light-emitting electrode of the ceramic metal halide lamp in Example 1. The difference is that in Example 2, the material of the electrode rod 3 includes tungsten, hafnium oxide and Yttrium oxide, the total mass percentage of hafnium oxide and yttrium oxide in the electrode rod 3 is 2%, the rest is tungsten, and the mass ratio of hafnium oxide to yttrium oxide is 1.9:1; the luminescent pill is the same as that in Example 1.

[0058] Apply ceramic metal halide lamp electrodes and luminescent pills to ceramic metal halide lamps. The luminous efficiency of the ceramic metal halide lamp is 74Lm / w, the color rendering index is 82, and the relative color temperature is 3920K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Grain weight | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com