Bilirubin adsorbent for blood perfusion

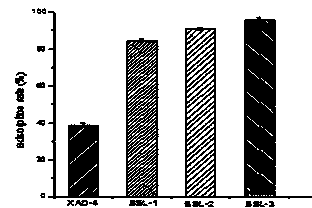

A blood perfusion and adsorbent technology, applied in the field of adsorbents for bilirubin and bile acid, can solve the problems of electrolyte disturbance, increased medical expenses for patients, poor biocompatibility, etc., and achieves increased biocompatibility and excellent adsorption performance. , the effect of excellent blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of highly cross-linked macroporous microspheres

[0028] At room temperature, dissolve 10g of gelatin in 1000ml of water to make a 1.0% (mass fraction) aqueous solution, place it in a 2000ml three-necked flask and heat it to 45°C to fully dissolve the gelatin; mix 50g of styrene, 100g of divinylbenzene , 110g of toluene, 190g of liquid paraffin, 10g of oligostyrene (polymerization degree 1000) and 1.5g of azobisisobutylcyanide were mixed evenly and then added to the three-necked bottle, started to stir, and adjusted the speed to disperse the oil droplets into an appropriate size, and then suspended Polymerization, slowly heat up to 78°C at a speed of 1-2°C / 5 minutes, react for 3 hours, then slowly heat up to 85°C at a speed of 1-2°C / 5 minutes, react for 3 hours, and then heat up at a speed of 1-2°C / 5 minutes Slowly raise the temperature to above 95°C in 5 minutes, react for 5 hours, then stop the reaction, filter and wash to prepare Cross-linke...

Embodiment 2

[0030] Example 2 Preparation of highly cross-linked macroporous microspheres

[0031] At room temperature, dissolve 18g of polyvinyl alcohol in 1200ml of water to make a 1.5% (mass fraction) aqueous solution, place it in a 3000ml three-neck bottle and heat it to 45°C to fully dissolve the polyvinyl alcohol; 25g of styrene, 125g Divinylbenzene, 20g of oligomeric methacrylates, 80g of toluene, 25g of liquid paraffin, 25g of solid paraffin and 2.0g of benzoyl peroxide were evenly mixed and then added to the three-necked bottle, started stirring, and adjusted the speed to disperse the oil droplets. After suspension polymerization, slowly heat up to 78°C at a speed of 1-2°C / 5 minutes, react for 3 hours, then slowly heat up to 85°C at a speed of 1-2°C / 5 minutes, react for 3 hours, and then react for 1-2 °C / 5 minutes to slowly raise the temperature to above 95 °C, react for 5 hours, then stop the reaction, filter and wash to prepare high Cross-linked polystyrene-divinylbenzene ma...

Embodiment 3

[0033] Example 3 Preparation of highly cross-linked ultra-macroporous microspheres

[0034] At room temperature, dissolve 20g of polyvinyl alcohol in 1000ml of water to make a 2.0% (mass fraction) aqueous solution, place it in a 2000ml three-necked bottle and heat it to 45°C to fully dissolve the polyvinyl alcohol; dissolve 150g of divinylbenzene , 200g of toluene, 190g of solid paraffin, 15g of polyvinyl acetate (polymerization degree 500) and 1.5g of benzoyl peroxide were mixed evenly and then added to the three-necked bottle, started to stir, and adjusted the speed to disperse the oil droplets into an appropriate size, and then suspended polymerization , Slowly raise the temperature to 78°C at a speed of 1-2°C / 5 minutes, react for 3 hours, then slowly raise the temperature to 85°C at a speed of 1-2°C / 5 minutes, react for 3 hours, and then react at a speed of 1-2°C / 5 Slowly heat up to above 95°C at a speed of 1 minute, react for 5 hours, then stop the reaction, filter and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com