Laser interference nanolithography system for one-step titanium alloy implant surface texturing and modification

A laser interference and nano-lithography technology, which is applied in the field of laser interference nano-lithography system for one-step texture modification on the surface of titanium alloy implants, can solve the lack of osteoinductive effect, failure and complications, and the ability to combine with surrounding bone tissue Poor problems, to achieve the effect of enhancing titanium alloy implant-osseointegration ability, changing roughness and biocompatibility, and improving biomechanical bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

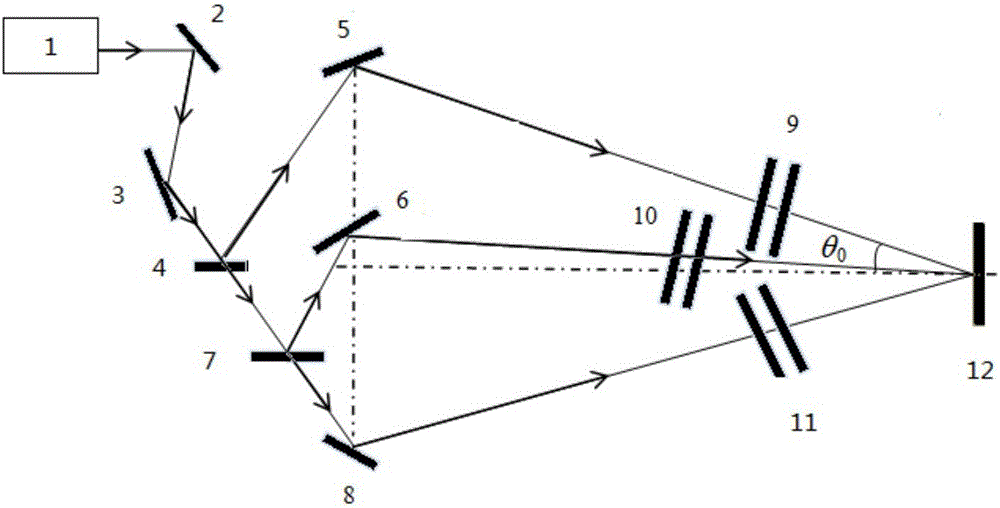

[0021] Using Matlab to simulate the three-beam interference pattern, theoretical analysis and experimental research modulated multi-beam interference to obtain a multi-period micro-nano hybrid structure. Based on the analysis of electromagnetic wave theory, a mathematical physical model is established, and the combination of software simulation and actual lithography is used to analyze the interference mechanism of the modulation phenomenon under specific parameter conditions, and the micron-level modulation period consistent with the simulated structure is obtained by precisely controlling the pulsed laser energy. and micro-nano hybrid structures with nanoscale feature sizes. Based on the results of theoretical and experimental analysis, a three-beam interference lithography system is built, such as figure 1 shown. Laser 1 emits a beam of laser light that passes through high reflection mirror 2, high reflection mirror 3, beam splitter 4 and high reflection mirror 5, and reac...

Embodiment 2

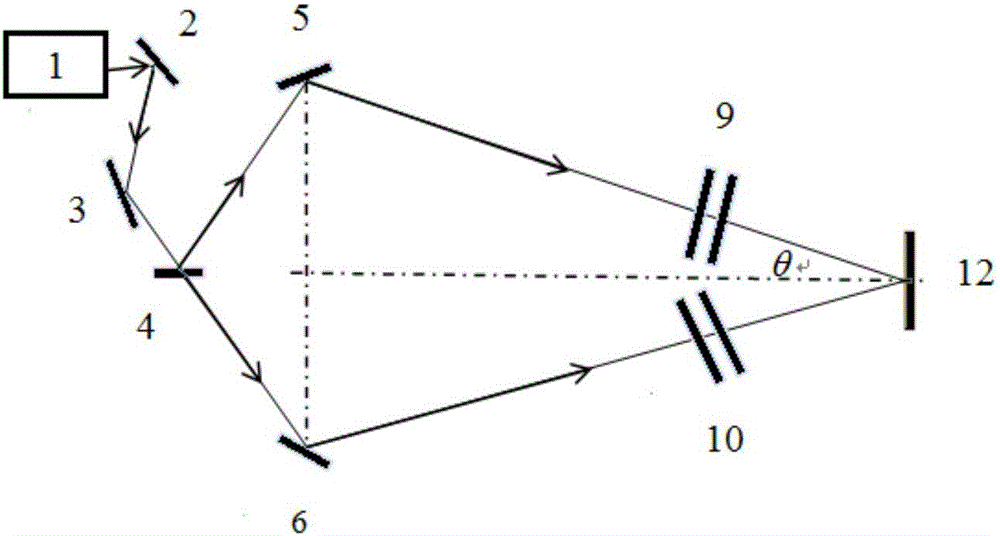

[0023] First, use Matlab to simulate the two-beam interference pattern, theoretically analyze and experiment to study the interaction mechanism between the interference light and the material, determine the lithography threshold of the material and realize quantitative nano-lithography. Study the interference lithography threshold of a given material relative to a given laser in a specific environment, and establish mathematical and physical models such as single temperature, double temperature, and molecular dynamics to study the non-equilibrium heat conduction process between interference light and solid materials. The consistency of the interference lithography pattern with the simulated structure is ensured by precise control of the pulsed laser energy. Based on the results of theoretical and experimental analysis, a two-beam interference lithography system is built, such as image 3 shown. Laser 1 emits a beam of laser light that passes through high reflection mirror 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com