Composite damping coating

A composite damping and damping coating technology, which is applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve environmental hazards and other problems, and achieve high loss factor, significant sound insulation effect, and increased specific gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

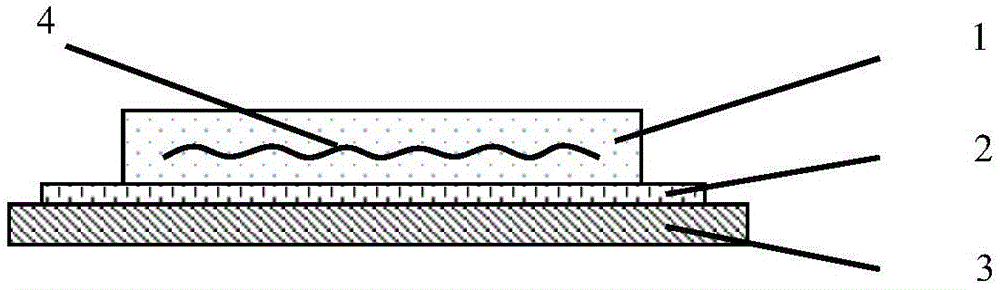

[0037] In this embodiment, a composite damping coating includes a damping layer and a constrained layer, the damping layer is a solvent-free modified polyurethane damping coating, and the constrained layer is a solvent-free modified epoxy resin constrained coating;

[0038] The solvent-free modified polyurethane damping coating includes the following raw materials in parts by weight:

[0039] A, 100 parts by weight of mixed polyurethane prepolymer (purchased from a damping material company in Macheng City, Hubei Province); Prepared by specific reaction, the hydroxyl polyol is composed of polyester, polyether polyol and castor oil with a mass ratio of 1:1:3.

[0040] B, 30 parts by weight of a hydroxyl-terminated compound; the hydroxyl-terminated compound is mixed from the following raw materials by weight:

[0041] Castor oil polyol 80 parts by weight;

[0042] 30 parts by weight of glycerol;

[0043] 2 parts by weight of silane coupling agent.

[0044] C, 5 parts by weigh...

Embodiment 2

[0054] In this embodiment, a composite damping coating includes a damping layer and a constrained layer, the damping layer is a solvent-free modified polyurethane damping coating, and the constrained layer is a solvent-free modified epoxy resin constrained coating;

[0055] The solvent-free modified polyurethane damping coating includes the following raw materials in parts by weight:

[0056] A, 150 parts by weight of the mixed polyurethane prepolymer; the mixed polyurethane prepolymer is prepared by reacting hydroxypolyol and isophorone diisocyanate in a molar ratio of 40:60, and the hydroxypolyol is It is composed of polyester, polyether polyol and castor oil in a mass ratio of 1:1:3.

[0057] B, 50 parts by weight of a hydroxyl-terminated compound; the hydroxyl-terminated compound is mixed from the following raw materials by weight:

[0058] Castor oil polyol 100 parts by weight;

[0059] 40 parts by weight of glycerol;

Embodiment 3

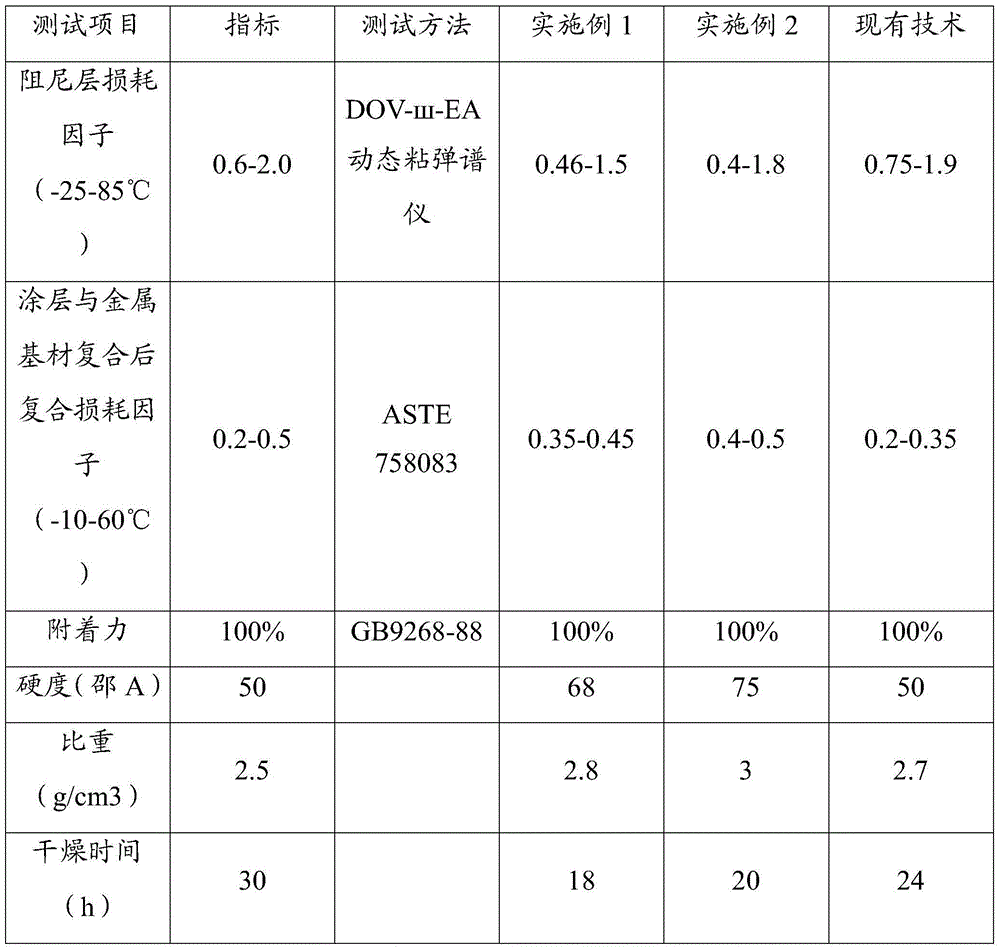

[0070] Embodiment 3 performance test

[0071] The composite damping coating that above-mentioned embodiment obtains carries out performance test, and the result is as follows:

[0072]

[0073] It can be seen from the data in the above table that the damping layer of the present invention is solvent-free modified polyurethane, while the damping layer in the prior art is polyether urethane; and the fillers are also different. The fillers of the present invention are carbon fibers, which are light, thin and flexible. Good performance, while the fillers in the prior art composite coatings are scaly fillers. Compared with the existing composite coating, the damping layer loss factor and composite loss factor of the present invention are superior, the damping area is wide, and the hardness is increased, the specific gravity is increased, the sound insulation effect is more significant, the drying time is shortened, and the construction is more convenient. No cracking occurs dur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com