Titanium-dioxide charcoal composite material and preparation method thereof

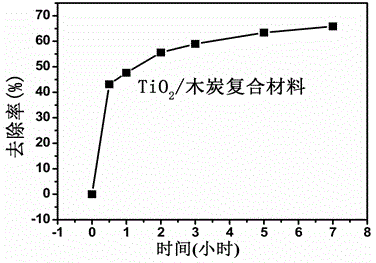

A technology of titanium dioxide and composite materials, applied in chemical instruments and methods, other chemical processes, chemical/physical processes, etc., can solve the problem of decreased adsorption active sites and catalytic active sites, insufficient binding force between carbon materials and titanium dioxide, and reduced carbon Material active adsorption sites and other issues, to achieve high adsorption/catalysis synergistic effect, good adsorption/photocatalytic synergistic treatment effect, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

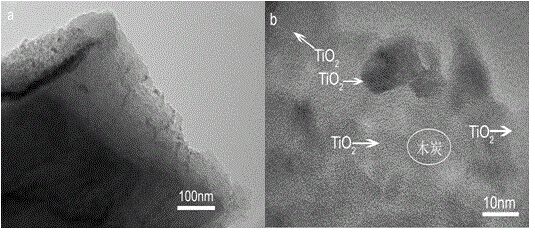

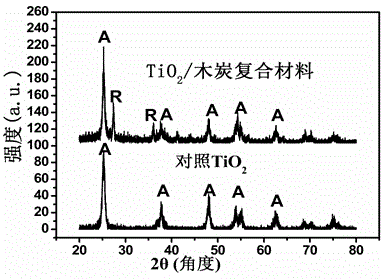

[0040] The mass percentage of charcoal in the composite material of titanium dioxide and charcoal described in this example is 38%, the microstructure of the carbon maintains the structure of the wood structure, the titanium dioxide is uniformly dispersed on the surface of the charcoal, and the titanium dioxide has both anatase and rutile phases, The mass ratio of anatase and rutile phases is 82:28, and the particle size of titanium dioxide is 12 nm.

[0041] The preparation method of the composite material of titanium dioxide and charcoal described in this embodiment specifically includes the following steps:

[0042] (1) Pretreatment of wood-based biological templates: cut paulownia into small pieces (length, width and height 50mm × 20mm × 20mm), then immersed in 2 mol / L nitric acid at 60 °C for 12 h, repeated twice, and then with anhydrous ethanol Immerse at 60°C for 12h, repeat 2 times, and finally soak with distilled water at 80°C for 12h, repeat 2 times, and dry at 60°C ...

Embodiment 2

[0049] The mass percentage of charcoal in the composite material of titanium dioxide and charcoal described in this example is 30%, the microstructure of the carbon maintains the structure of the wood structure, the titanium dioxide is uniformly dispersed on the surface of the charcoal, and the titanium dioxide has both anatase and rutile phases. The mass ratio of anatase and rutile phases is 78:22, and the particle size of titanium dioxide is 15 nm.

[0050] The preparation method of the composite material of titanium dioxide and charcoal described in this embodiment specifically includes the following steps:

[0051] (1) Pretreatment of wood-based biological templates: Cut thorn trees into small pieces (length, width and height 50mm×20mm×20mm), and then immerse them in 2mol / L nitric acid at 40°C for 6h, repeat twice, and then use anhydrous Dipping in ethanol at 60°C for 6h, repeated twice, and finally soaking in distilled water for 12h at 40°C, repeated three times, and dryi...

Embodiment 3

[0058] The mass percentage of charcoal in the composite material of titanium dioxide and charcoal described in this example is 40%, the microstructure of the carbon maintains the structure of the wood structure, the titanium dioxide is uniformly dispersed on the surface of the charcoal, and the titanium dioxide has both anatase and rutile phases. The mass ratio of anatase and rutile phases is 75:25, and the particle size of titanium dioxide is 12 nm.

[0059] The preparation method of the composite material of titanium dioxide and charcoal described in this embodiment specifically includes the following steps:

[0060] (1) Pretreatment of wood-based biological templates Cut the thorn tree into small pieces (length, width and height 50mm×20mm×20mm), then soaked in 2mol / L nitric acid at 40°C for 6h, repeated twice, and then used anhydrous ethanol Immerse at 60°C for 6h, repeat 2 times, and finally soak with distilled water for 12h at 40°C, repeat 3 times, and dry at 40°C for 12h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com