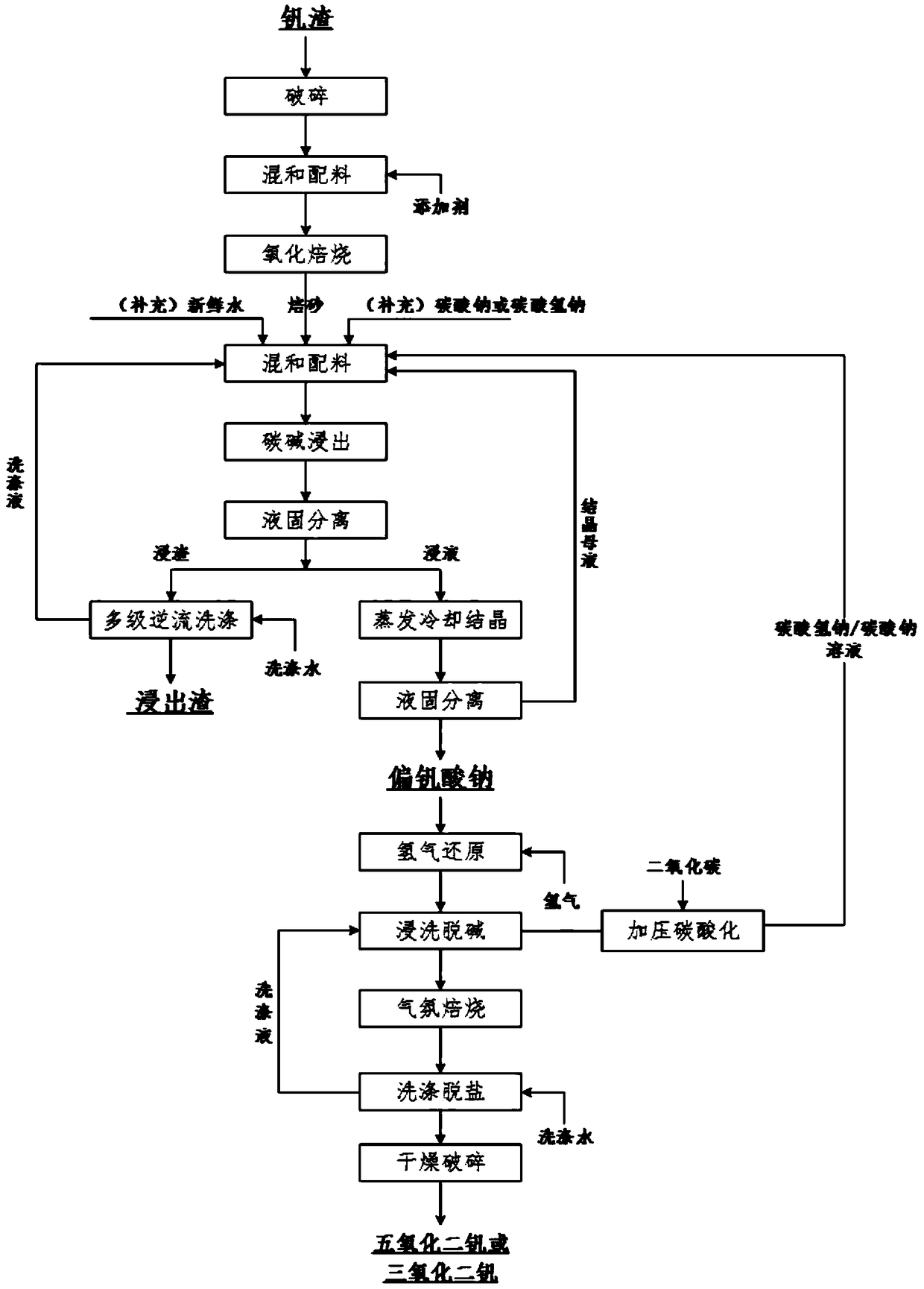

A process for the clean production of vanadium oxides by carbon-alkali leaching of vanadium slag and hydrogen reduction

A technology of vanadium oxide and reduction method, which is applied in the field of vanadium oxide production and vanadium slag carbon alkali leaching hydrogen reduction method to cleanly produce vanadium oxide, which can solve the problems of low vanadium leaching rate and lengthy vanadium precipitation process, and achieve vanadium High recovery rate, short process flow, and the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) The vanadium slag is crushed and ground to a particle size of less than 74 microns, and calcium oxide and vanadium slag are added to mix the ingredients, and the calcium salt and V in the mixture are controlled. 2 o 5 The molar ratio of the vanadium slag is 0.05, and it is oxidized and roasted at 800 ° C for 90 minutes. During the roasting process, the furnace door is ajar to ensure that the vanadium slag is in full contact with the air;

[0053] (2) Get 40g of pre-oxidized vanadium slag, add it to 12% sodium carbonate solution, mix well, wherein the volume of sodium carbonate solution is 200mL, leaching reaction in autoclave, control reaction temperature 100 ℃, reaction time 2h;

[0054] (3) The solution obtained by filtration is concentrated by vacuum evaporation at 70° C., cooled and crystallized at room temperature, filtered to obtain sodium metavanadate crystals and crystallization mother liquor, and the crystallization mother liquor is supplemented with sodium...

Embodiment 2

[0060] (1) The vanadium slag is crushed and ground to a particle size of less than 74 microns, and magnesium oxide, magnesium carbonate and vanadium slag are added to mix the ingredients, and the magnesium salt and V in the mixture are controlled. 2 o 5 The molar ratio of the vanadium slag is 2, and it is oxidized and roasted at 700°C for 150 minutes. During the roasting process, the furnace door is ajar to ensure that the vanadium slag is in full contact with the air;

[0061] (2) Take 40g of pre-oxidized vanadium slag, add it to 10% sodium carbonate solution, mix evenly, wherein the volume of sodium carbonate solution is 200mL, leaching reaction in an autoclave, control the reaction temperature to 120°C, and the reaction time to 3h;

[0062] (3) The solution obtained by filtration is concentrated by vacuum evaporation at 80° C., cooled and crystallized at room temperature, filtered to obtain sodium metavanadate crystals and crystallization mother liquor, and the crystallizat...

Embodiment 3

[0068] (1) The vanadium slag is crushed and ground to a particle size of less than 74 microns, and magnesium carbonate, calcium hydroxide and vanadium slag are added to mix the ingredients, and the magnesium salt and V in the mixture are controlled. 2 o 5 The molar ratio is 2 and the calcium salt and V 2 o 5 The molar ratio is 1.5, and it is oxidized and roasted at 750°C for 120 minutes. During the roasting process, the furnace door is ajar to ensure that the vanadium slag is in full contact with the air;

[0069] (2) Take 40g of pre-oxidized vanadium slag, add it to 15% sodium bicarbonate solution, mix well, wherein the volume of sodium bicarbonate solution is 200mL, leaching reaction in an autoclave, control the reaction temperature to 90°C, and the reaction time to 4h;

[0070] (3) The solution obtained by filtration is concentrated by vacuum evaporation at 70° C., cooled and crystallized at room temperature, filtered to obtain sodium metavanadate crystals and crystalliza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com