Flame-retardant polyester composite material and preparation method thereof

A composite material, flame retardant polyester technology, applied in the field of materials, can solve the problems of plastic plasticization, reducing product durability temperature, product durability temperature reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Place the styrene-ethylene-butadiene-styrene copolymer and paraffin processing oil in a high-speed mixer at a ratio of 2:1 by weight for high-speed mixing. After about 10 minutes, the processing oil and styrene -The ethylene-butadiene-styrene copolymer reaches a uniformly mixed state, and it is taken out for use;

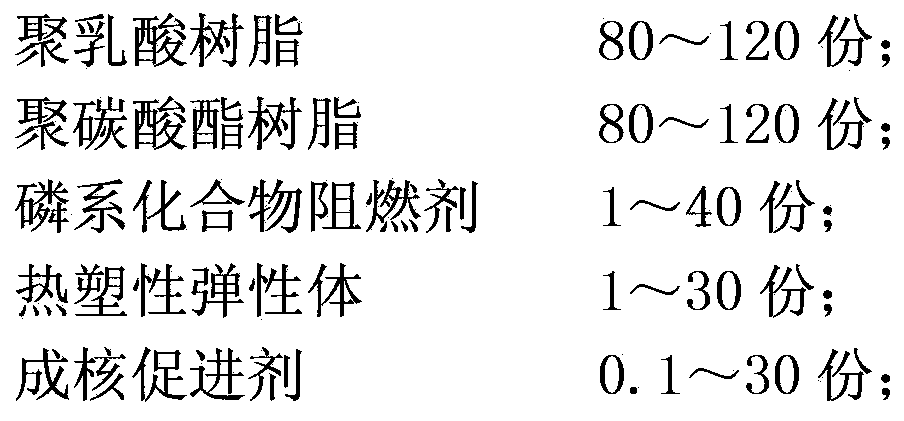

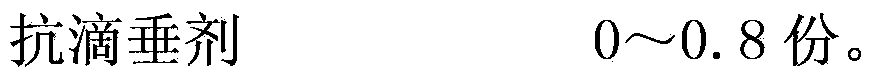

[0043] (2) Take 5 parts by weight of the mixture obtained in step (1), 100 parts by weight of polylactic acid resin, 100 parts by weight of polycarbonate resin, 30 parts by weight of phosphorus compound flame retardant with structural formula FR-1, and 5 parts by weight of talc Parts and 2 parts by weight of chain extender are first mixed evenly by dry mixing, and then introduced into a twin-screw extruder with a volumetric feeder for melt-kneading processing at 180-210°C, after melt-kneading processing The obtained extruded bar is cooled by cold water into a solid state, and cylindrical particles are produced by a pelletizer;

[0044] (3) Dry the above-menti...

Embodiment 2

[0046] (1) Place the styrene-ethylene-butadiene-styrene copolymer and paraffin processing oil in a high-speed mixer at a ratio of 2:1 by weight for high-speed mixing. After about 10 minutes, the processing oil and styrene -The ethylene-butadiene-styrene copolymer reaches a uniformly mixed state, and it is taken out for use;

[0047] (2) Take 5 parts by weight of the mixture obtained in step (1), 100 parts by weight of polylactic acid resin, 100 parts by weight of polycarbonate resin, 30 parts by weight of phosphorus-based compound flame retardant with structural formula FR-2, and 5 parts by weight of talc Parts, 2 parts by weight of the chain extender, 0.4 parts by weight of the anti-dripping agent, firstly mixed uniformly by dry mixing, and then introduced into the twin-screw extruder with a volumetric feeder for melting and mixing at 180-210°C Kneading process, the extruded strip obtained after melt kneading process is cooled into a solid state by cold water, and cylindrical pa...

Embodiment 3

[0050] (1) Place the styrene-ethylene-butadiene-styrene copolymer and paraffin processing oil in a high-speed mixer at a ratio of 2:1 by weight for high-speed mixing. After about 10 minutes, the processing oil and styrene -The ethylene-butadiene-styrene copolymer reaches a uniformly mixed state, and it is taken out for use;

[0051] (2) Take 5 parts by weight of the mixture obtained in step (1), 100 parts by weight of polylactic acid resin, 100 parts by weight of polycarbonate resin, 30 parts by weight of phosphorus compound flame retardant with structural formula FR-3, and 5 parts by weight of talc Parts, 2 parts by weight of the chain extender, 0.4 parts by weight of the anti-dripping agent, firstly mixed uniformly by dry mixing, and then introduced into the twin-screw extruder with a volumetric feeder for melting and mixing at 180-210°C Kneading process, the extruded strip obtained after melt kneading process is cooled into a solid state by cold water, and cylindrical particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com