Lattice-matched LED epitaxial structure and preparation method thereof

An epitaxial structure, lattice matching technology, applied in electrical components, circuits, semiconductor devices and other directions, can solve the problems of large lattice, band bending, can not effectively alleviate lattice strain, etc., to improve radiation recombination efficiency and internal quantum luminescence Efficiency, the effect of slowing down the decrease in luminous efficiency, and improving the quality of crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

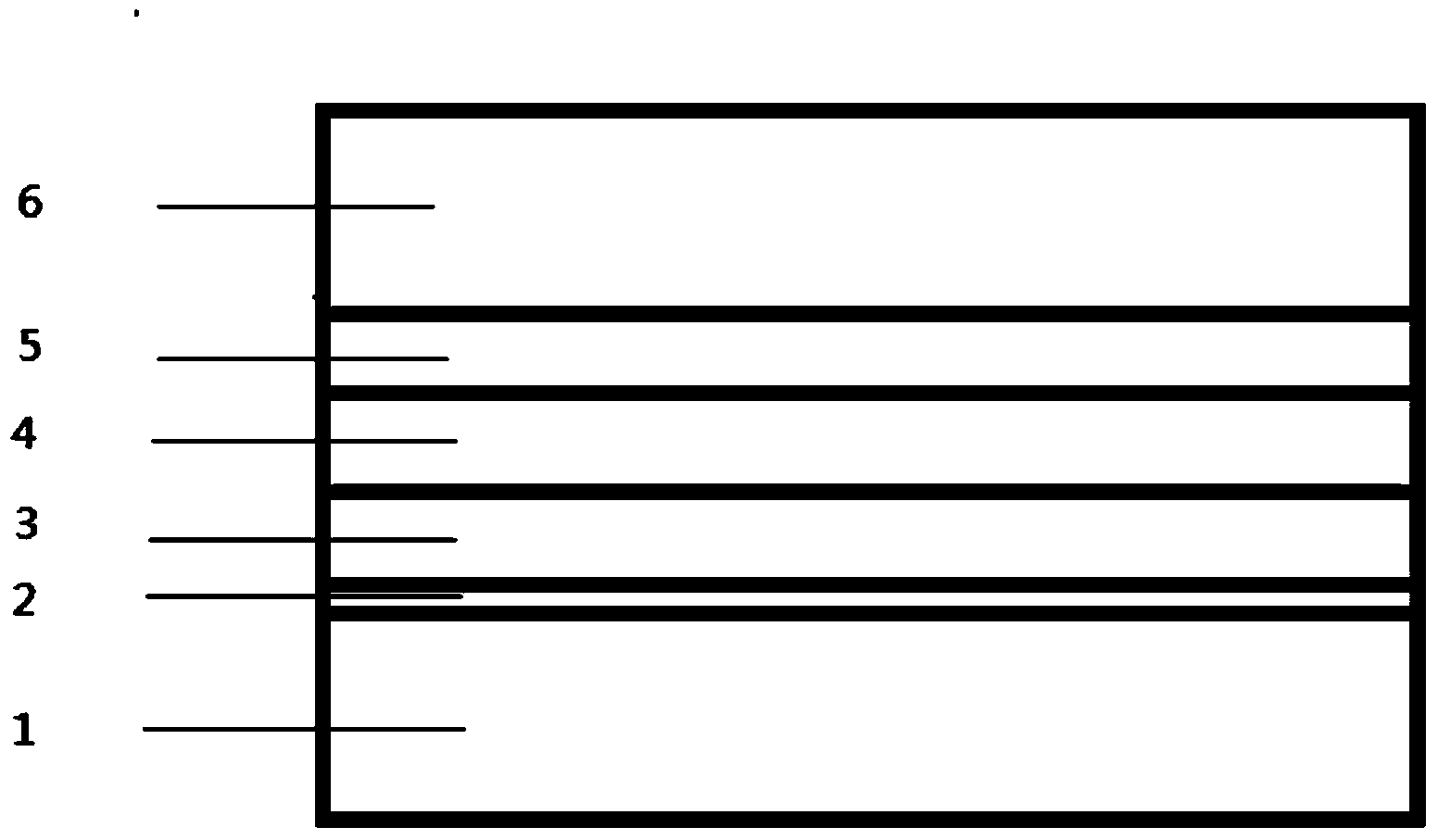

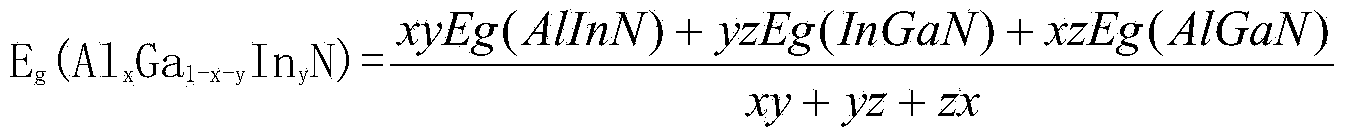

[0045] A lattice-matched LED epitaxial structure, comprising Al with a thickness of 25 nm on the substrate layer 1 0.51 Ga 0.18 In 0.31 N nucleation layer 2, undoped Al with a thickness of 1.2 μm 0.51 Ga 0.18 In 0.31 N layer 3, Si-doped Al with a thickness of 1.5 μm 0.51 Ga 0.18 In 0.31 N layer 4, multi-quantum well light-emitting layer 5 and Mg-doped Al with a thickness of 200nm 0.51 Ga 0.18 In 0.31 N layer 6; the multi-quantum well light-emitting layer 5 is 9 repeating periods and the thickness is respectively 3nm thick In 0.2 Ga 0.8 N well layer and 12nm thick Al 0.51 Ga 0.18 In 0.31 N barrier layer composition; the 1.5μm Si-doped Al 0.51 Ga 0.18 In 0.31 The N layer 4 is composed of a highly doped layer of 1.3 μm and a low doped layer of 0.2 μm, and the Si doping concentration of the high doped layer is 8×10 18 cm -3 , the Si doping concentration of the low-doped layer is 2×10 17 cm -3 .

Embodiment 2

[0047] The preparation method of the LED structure described in embodiment 1, the specific steps are as follows:

[0048] 1. Place the sapphire substrate in a hydrogen atmosphere, heat it to 1080°C and keep it for 5 minutes to remove H on the surface of the substrate 2 O and O 2 ;

[0049] 2. Under the condition of hydrogen atmosphere, adjust the temperature to heat the substrate layer to 540°C, press 500Torr, and keep it for 5 minutes. Use TMGa as the Ga source, NH3 as the N source, TMAl as the Al source, and TMIn as the In source to start growing Al 0.51 Ga 0.18 In 0.31 The N nucleation layer has a thickness of 30nm; then adjust the temperature in the MOCVD reaction chamber to 860°C and keep it for 10min to make the Al 0.51 Ga 0.18 In 0.31 The N nucleation layer undergoes recrystallization;

[0050] 3) Keep the temperature in the MOCVD reaction chamber at 860°C and the pressure at 350Torr to grow undoped Al 0.51 Ga 0.18 In 0.31 N layer 1.2μm, n-type doped Al 0.51 ...

Embodiment 3

[0054] A lattice-matched LED epitaxial structure, comprising Al with a thickness of 25 nm on the substrate layer 1 0.63 Ga 0.09 In 0.28 N nucleation layer 2, undoped Al with a thickness of 1.2 μm 0.63 Ga 0.09 In 0.28 N layer 3, Si-doped Al with a thickness of 1.5 μm 0.63 Ga 0.09 In 0.28 N layer 4, multi-quantum well light-emitting layer 5 and Mg-doped Al with a thickness of 200nm 0.63 Ga 0.09 In 0.28 N layer 6; the multi-quantum well light-emitting layer 5 is 9 repeating periods and the thickness is respectively 3nm thick In 0.15 Ga 0.85 N well layer and 12nm thick Al 0.63 Ga 0.09 In 0.28 N barrier layer composition; the 1.5μm Si-doped Al 0.63 Ga 0.09 In 0.28 The N layer 4 is composed of a highly doped layer of 1.3 μm and a low doped layer of 0.2 μm, and the Si doping concentration of the high doped layer is 8×10 18 cm -3 , the Si doping concentration of the low-doped layer is 2×10 17 cm -3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com