Composite diaphragm for battery and preparation method thereof

A composite membrane and battery technology, applied in the field of electrochemical batteries, can solve the problems of unstable interface between electrolyte and electrode material, slow ion transmission, battery performance degradation, etc., to alleviate uneven corrosion, improve high-current charge-discharge performance, The effect of reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

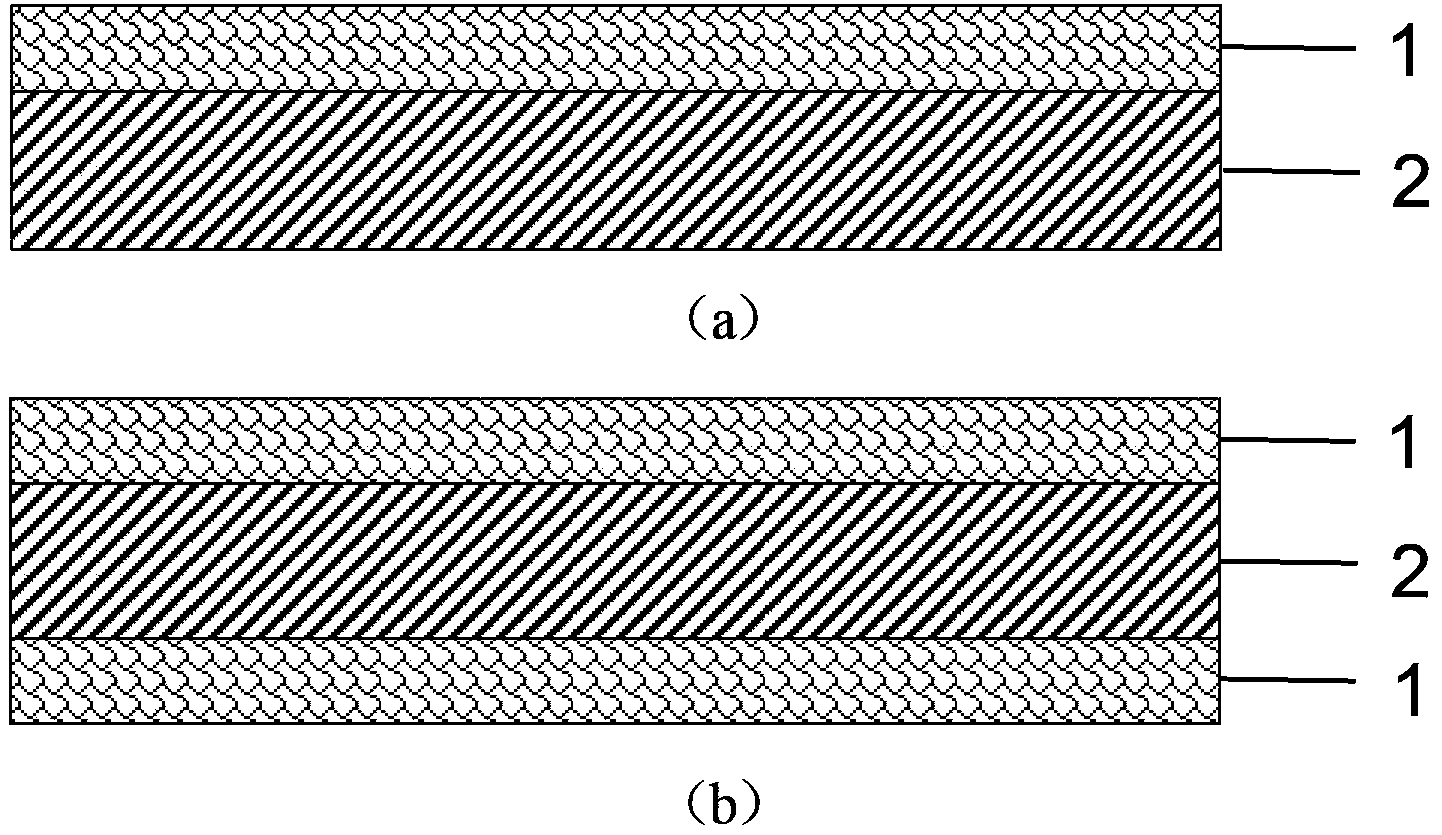

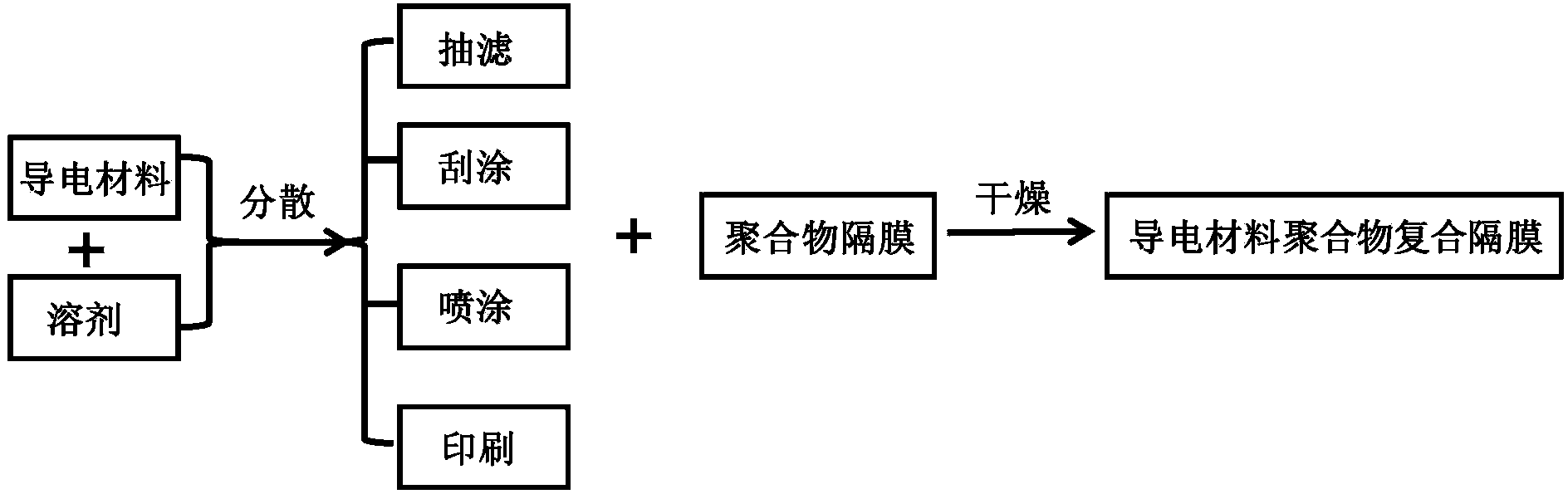

[0038] Add 100mg of graphene into 200mL ethanol and disperse uniformly by ultrasonic for 0.5h (the content of graphene in the dispersion is 0.5mg / mL) and filter it onto the continuously rolling polypropylene microporous diaphragm to form a strip-shaped composite diaphragm. After drying under vacuum for 12 hours to remove the solvent, a composite diaphragm of graphene film layer and polymer layer (polypropylene microporous diaphragm) can be obtained. The composite diaphragm is shown in image 3 (a) (shown in the lower part), the graphene-polypropylene composite diaphragm is sliced and the photo is shown in image 3 (b). The scanning electron microscope picture of the graphene thin film layer in the obtained composite separator is shown in Figure 4 (a-b), it can be seen that the graphene sheets are tightly stacked, and the lateral size of graphene is 5-50 microns.

[0039] Figure 5 In order to test the lithium iron phosphate cathode material in the lithium-ion battery, th...

Embodiment 2

[0043] The graphene in Example 1 was replaced by a composite of multi-walled carbon nanotubes and conductive carbon black. After being uniformly dispersed in NMP, a PP diaphragm with a thickness of 20 μm and a pore diameter of 100 nm was formed on one side with a thickness of A conductive layer of 2 μm constitutes a composite separator for testing the battery performance of the lithium iron phosphate cathode material, and can obtain battery performance similar to that of Example 1, and is obviously better than that of Comparative Example 1.

Embodiment 3

[0045] Replace the graphene in Example 1 with a composite of mesoporous carbon and microporous carbon spheres. After uniform dispersion in DMF, use the method of scraping to form a thickness of A conductive layer of 5 μm constitutes a composite separator for testing the battery performance of the lithium iron phosphate positive electrode material. The battery performance similar to that of Example 1 can be obtained, and it is obviously better than the battery performance of Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com