a metal cleaner

A technology of metal cleaning agent and nonylphenol polyoxyethylene ether, which is applied in the field of cleaning agents, can solve problems such as unsafe use, pollute the environment, and endanger the health of users, and achieve good rust removal effect, no pollution to the environment, and safe good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Weigh 1kg of stearic acid, 5kg of citric acid, 1kg of lauric acid, 1kg of sodium bicarbonate, 0.5kg of chromic anhydride, 0.5kg of sodium silicate, HLB value of 14, pH value of 6 nonylphenol polyoxygen Put 4kg of vinyl ether and 87kg of water in a container and stir evenly to obtain a metal cleaning agent.

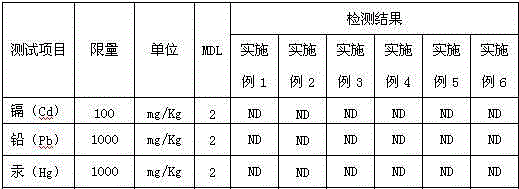

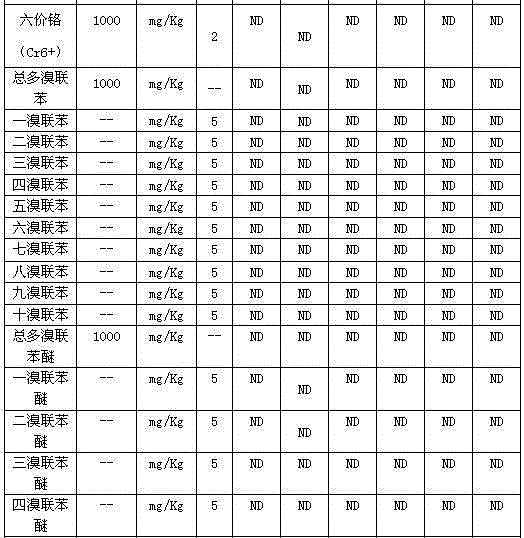

[0060] The metal parts cleaned by the metal cleaning agent prepared in this embodiment have no corrosion and no residue. The metal cleaning agent prepared in this example does not contain fluorine, chlorine, bromine, iodine, cadmium, lead, mercury, hexavalent chromium, polybrominated biphenyls, polybrominated diphenyl ethers, and complies with EN14582:2007 and ROHS Directive2011 / 65 / EU testing standards, environmental protection and safety Good, non-toxic, non-corrosive, and does not pollute the environment. The specific test results are shown in Table 1 and Table 2.

Embodiment 2

[0062] Weigh 3kg of stearic acid, 4kg of citric acid, 2kg of lauric acid, 1kg of sodium bicarbonate, 1.5kg of chromic anhydride, 0.5kg of sodium silicate, HLB value of 15, pH value of 6 nonylphenol polyoxygen Put 3kg of vinyl ether and 85kg of water in a container and stir evenly to obtain a metal cleaning agent.

[0063] The metal parts cleaned by the metal cleaning agent prepared in this embodiment have no corrosion and no residue. The metal cleaning agent prepared in this example does not contain fluorine, chlorine, bromine, iodine, cadmium, lead, mercury, hexavalent chromium, polybrominated biphenyls, polybrominated diphenyl ethers, and complies with EN14582:2007 and ROHS Directive2011 / 65 / EU testing standards, environmental protection and safety Good, non-toxic, non-corrosive, and does not pollute the environment. The specific test results are shown in Table 1 and Table 2.

Embodiment 3

[0065] Weigh 5kg of stearic acid, 5kg of citric acid, 5kg of lauric acid, 3kg of sodium bicarbonate, 2kg of chromic anhydride, 2kg of sodium silicate, HLB value of 15, pH value of 7 nonylphenol polyoxygen Put 4kg of vinyl ether and 74kg of water in a container and stir evenly to obtain a metal cleaning agent.

[0066] The metal parts cleaned by the metal cleaning agent prepared in this embodiment have no corrosion and no residue. The metal cleaning agent prepared in this example does not contain fluorine, chlorine, bromine, iodine, cadmium, lead, mercury, hexavalent chromium, polybrominated biphenyls, polybrominated diphenyl ethers, and complies with EN14582:2007 and ROHS Directive2011 / 65 / EU testing standards, environmental protection and safety Good, non-toxic, non-corrosive, and does not pollute the environment. The specific test results are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com