Charcoal-coated metal fluoride nano material with core-shell structure, preparation method and application of nano material as lithium battery positive electrode material

A core-shell structure, nanomaterial technology, applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problem that fluoride and conductive materials cannot form a stable phase interface, fluoride and conductive materials are easy to peel off, and composite materials have a wide size distribution. and other problems, to achieve the effect of reducing charge transfer resistance, improving surface chemical activity, and improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 2g ferrocene (C 10 h 10 Fe) and 16g ammonium fluoride (NH 4 F), and mix the two evenly. Put the mixture into an autoclave, under a nitrogen atmosphere, raise the temperature from room temperature to 500 °C at a rate of 1.5 °C / min, keep it warm for 3 hours, then cool to room temperature, wash away unreacted ammonium fluoride with water to obtain the core-shell Structure of carbon-coated iron fluoride nanomaterials.

[0026] as attached figure 1 Scanning electron microscope (SEM) analysis showed that the prepared carbon-coated ferric fluoride was rod-shaped, with a diameter ranging from 100 to 200 nm and a length of 1 to 3 μm.

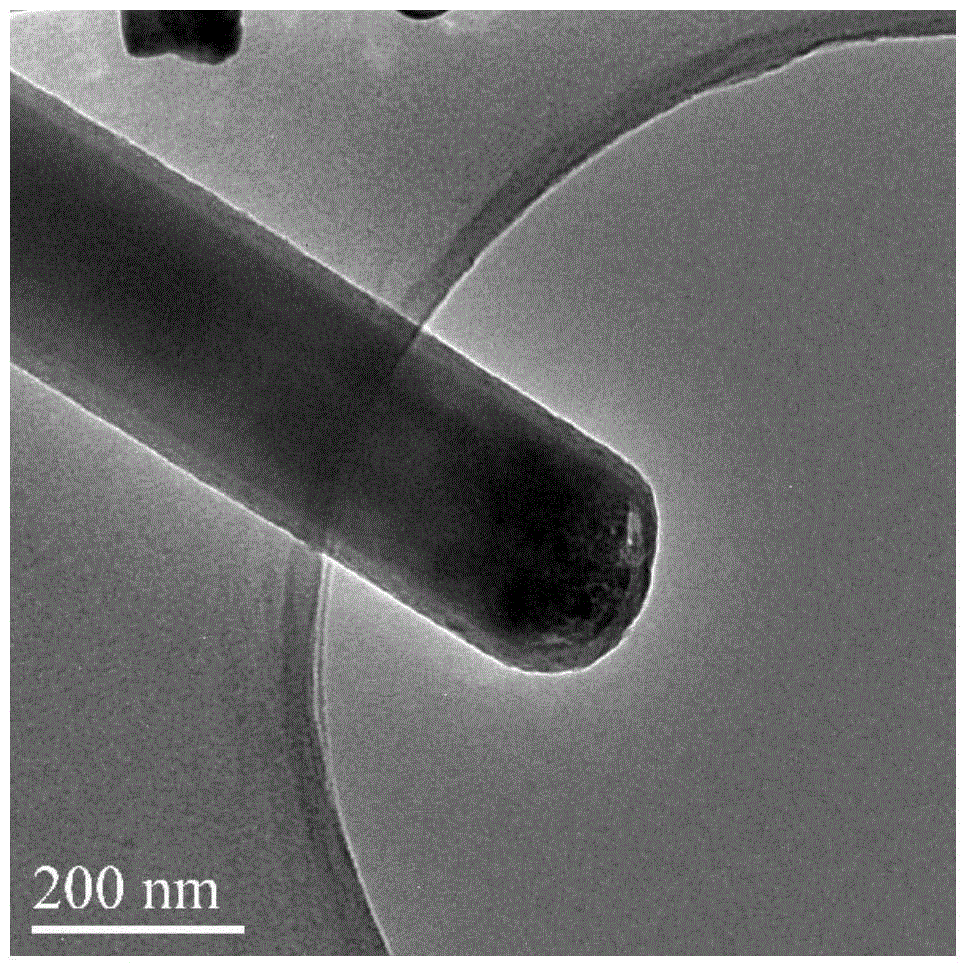

[0027] as attached figure 2 Transmission electron microscope (TEM) image test shows that the prepared carbon-coated ferric fluoride material has a core-shell structure, the shell layer is carbon, the thickness is 10-20nm, the core layer is ferric fluoride, and the diameter is 90-180nm.

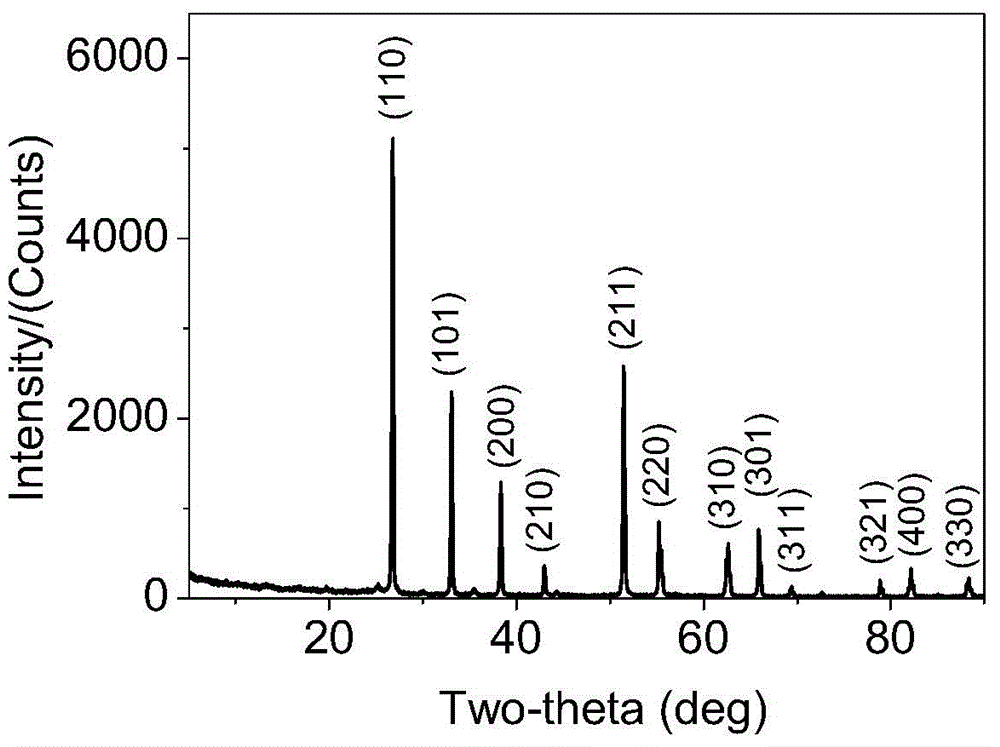

[0028] as attached image 3 X-ray diffraction ...

Embodiment 2

[0031] The operation method is the same as in Example 1, and the mass ratio is 1:4 to weigh 2g C 10 h 10 Fe and 8g NH 4 F, keeping other conditions unchanged. SEM analysis shows that the prepared carbon-coated ferric fluoride material has a rod-like structure with a diameter ranging from 150 to 200 nm and a length of 1 to 2 μm. The electrochemical performance test results show that the composite material has a reversible capacity of 320mAh / g at a current density of 50mA / g.

Embodiment 3

[0033] The operation method is the same as in Example 1, the reaction temperature is 600°C, and other conditions are kept unchanged. SEM analysis shows that the prepared carbon-coated ferric fluoride material has a rod-like structure, with a diameter ranging from 100 to 250 nm and a length of 2 to 3 μm. The electrochemical performance test results show that the composite material has a reversible capacity of 250mAh / g at a current density of 50mA / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com