Linkage screw return type oil sand dry distillation process system

A process system and reprogrammed technology, which is applied in special forms of dry distillation, petroleum industry, direct heating dry distillation, etc., can solve the problems of slow thermal decomposition of materials, complicated process, increased thermal resistance, etc., and achieve excellent integration performance and process flow Simple, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

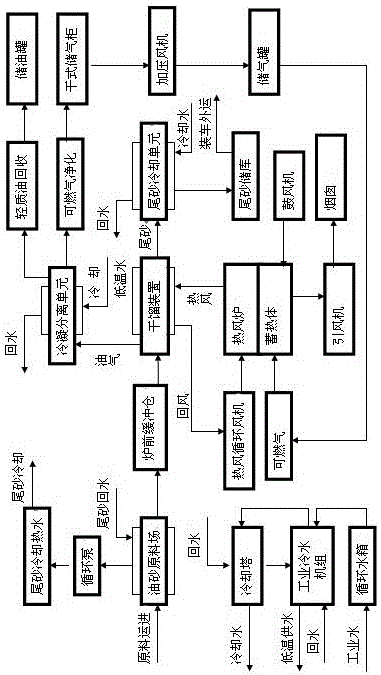

[0034] As shown in the figure, the linkage spiral return type oil sands carbonization process system consists of raw material drying unit, pyrolysis carbonization unit, heat storage swirl hot air unit, condensation separation unit, tailings cooling unit and corresponding public and auxiliary supporting units. The pyrolysis dry distillation unit and the thermal storage swirl hot air unit are the key equipment of this system.

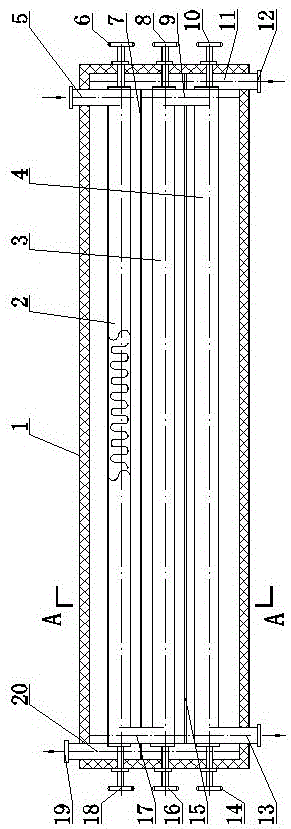

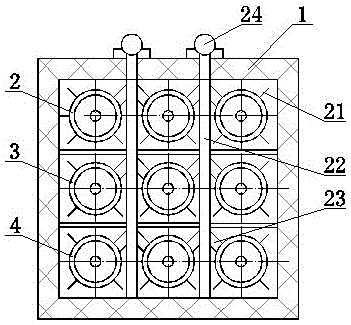

[0035] Wherein, the pyrolysis and carbonization unit adopts a linked spiral three-pass dry distillation device, and the linked spiral three-pass dry distillation device is composed of a heating box 1 and multiple sets of parallel three-pass screw machines arranged in the heating box 1. The three-return screw machine is composed of a preheating screw machine 2, a pyrolysis screw machine 3 and a dry distillation screw machine 4 connected end to end and vertically arranged from top to bottom. The tubes of the preheating screw machine 2 and the pyrolysis screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com