Shear thickening fluid microcapsule, reinforced high molecular material and preparation method and application of shear thickening fluid microcapsule and reinforced high molecular material

A polymer material and microcapsule technology, applied in the field of shear thickening fluid microcapsules, can solve the problems of poor processing fluidity and poor impact resistance, and achieve improved processing fluidity, good processing fluidity, excellent The effect of impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

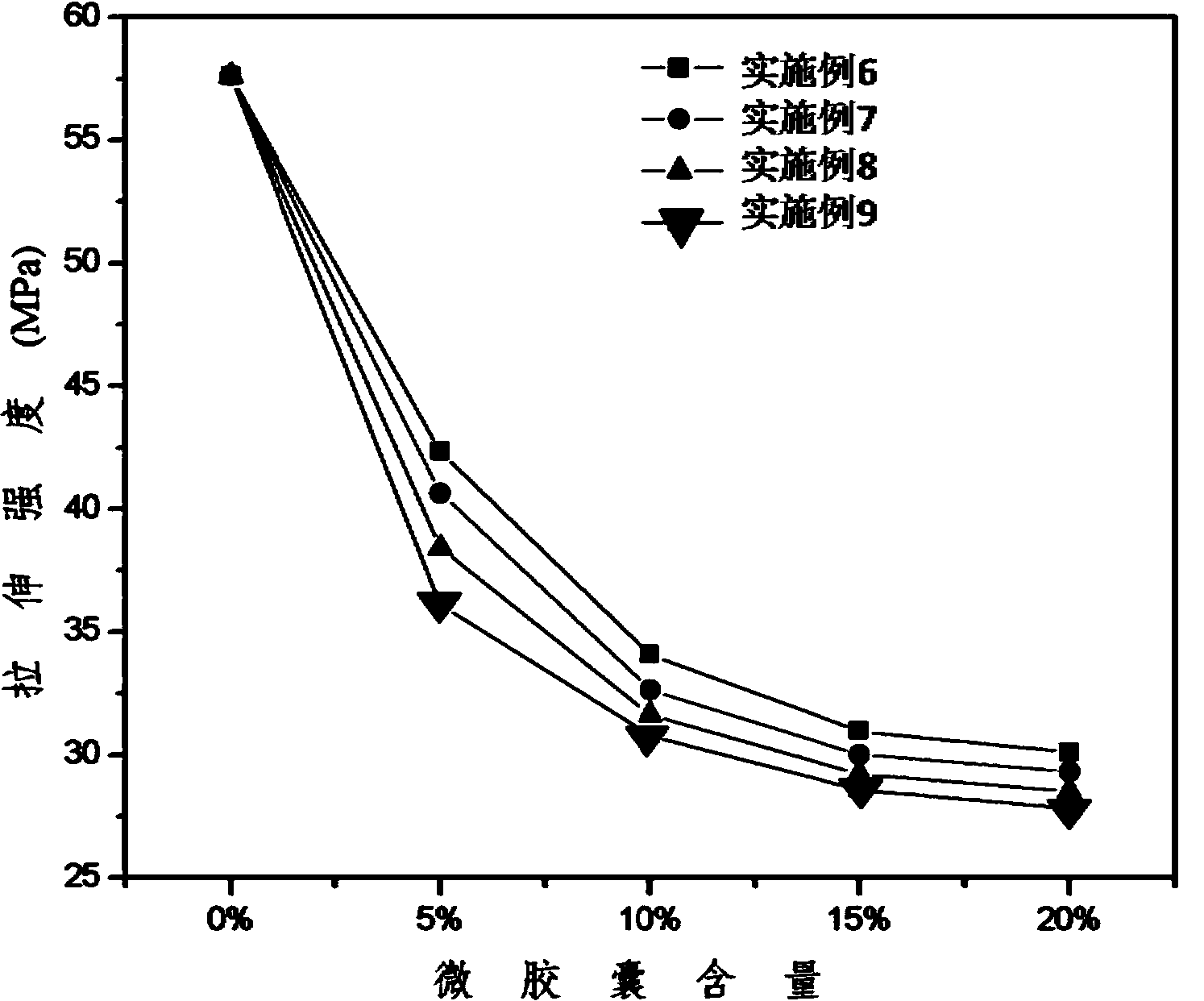

Examples

Embodiment 1

[0046] A preparation method for shear thickening fluid microcapsules, comprising the steps of:

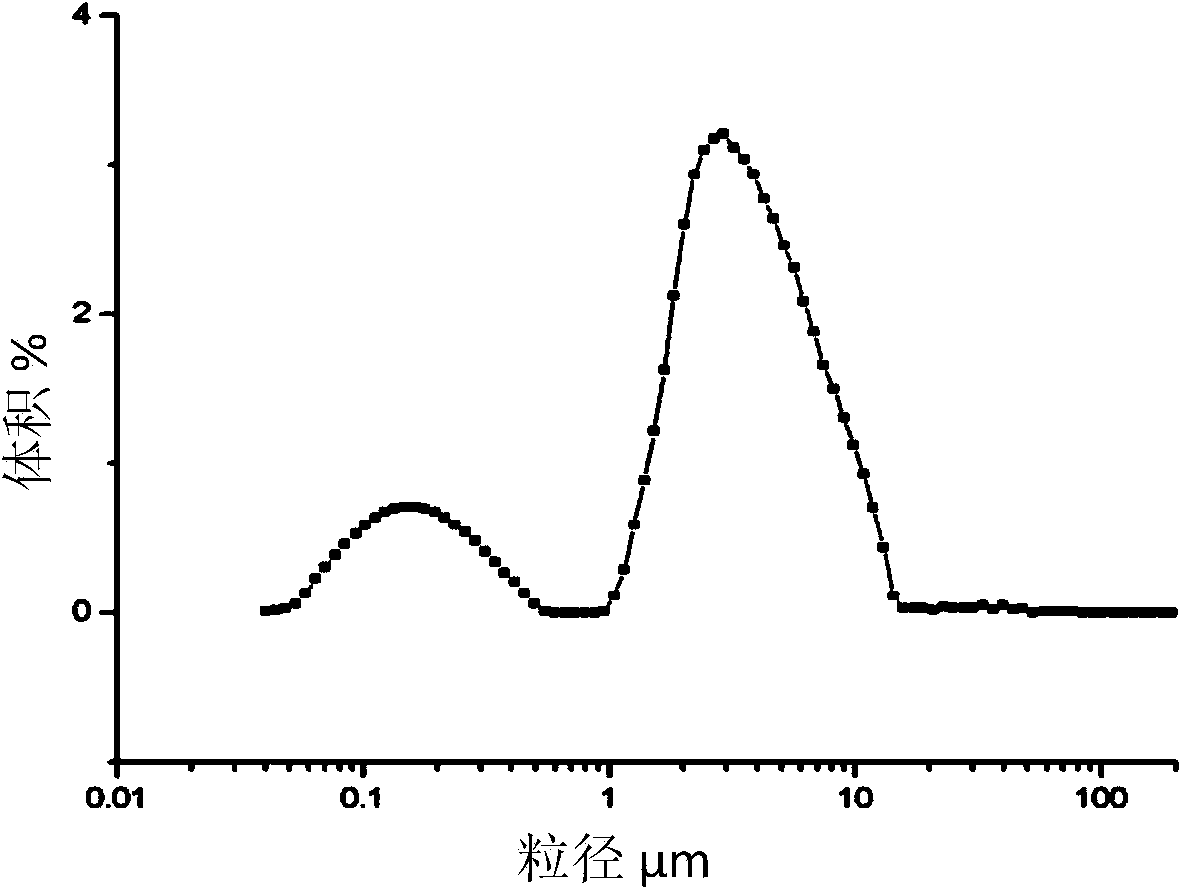

[0047] (1) In 190g of polyethylene glycol with a number average molecular weight of 400, add 10g of nano-silicon dioxide while stirring at a speed of 3000rpm with a high-speed shear emulsifier, shear emulsification for 30min, and ultrasonically defoam for 30min to obtain shear cut thickened fluid;

[0048] (2) 3g emulsifier (Span80 and Tween80 compounding, weight ratio is 3: 1) and 77g n-octane are mixed, under the 9000rpm rotating speed of high-speed shear emulsifier, add the shear that 20g step (1) makes Thicken the fluid, mix and stir for 15 to 20 minutes to obtain an emulsion;

[0049] (3) At 80°C and a stirring speed of 800rpm, add 32ml of cyclohexane dissolved with 6g of toluene diisocyanate into 67g of emulsion, react at 80°C for 90min, filter the reaction product with suction, and wash with ethanol Three times, and then dried in a vacuum oven at 80°C for 4 hours to obtain...

Embodiment 2

[0051] A preparation method for shear thickening fluid microcapsules, comprising the steps of:

[0052] (1) In 160g of polyethylene glycol with a number average molecular weight of 600, add 40g of nano-silica while stirring at a speed of 3000rpm with a high-speed shear emulsifier, emulsify by shearing for 30min, and ultrasonically defoam for 60min to obtain shear cut thickened fluid;

[0053] (2) 3g emulsifier (Span80 and Tween80 compounding, weight ratio is 2: 1) and 77g n-octane are mixed, under the 9000rpm rotating speed of high-speed shear emulsifier, add the shear that 20g step (1) makes Thicken the fluid, mix and stir for 15 to 20 minutes to obtain an emulsion;

[0054] (3) At 80°C and a stirring speed of 800rpm, add 32ml of cyclohexane dissolved with 6g of diphenylmethane diisocyanate into 70g of the emulsion, react at 80°C for 90min, and filter the reaction product with suction. Wash it three times with ethanol, and then dry it in a vacuum oven at 80°C for 4 hours to...

Embodiment 3

[0056] A preparation method for shear thickening fluid microcapsules, comprising the steps of:

[0057] (1) In 190g of polyethylene glycol with a number average molecular weight of 400, add 10g of nano silicon dioxide while stirring at a speed of 3000rpm with a high-speed shear emulsifier, emulsify by shearing for 30min, and ultrasonically defoam for 40min to obtain shear cut thickened fluid;

[0058] (2) 3g emulsifier (Span80 and Tween80 compound, weight ratio is 5: 1) and 77g n-octane are mixed, under the 9000rpm rotating speed of high-speed shear emulsifier, add the shear that 20g step (1) makes Thicken the fluid, mix and stir for 15 to 20 minutes to obtain an emulsion;

[0059] (3) At 80°C and a stirring speed of 800rpm, add 32ml of cyclohexane dissolved with 6g of toluene diisocyanate into 67g of emulsion, react at 80°C for 90min, filter the reaction product with suction, and wash with ethanol Three times, and then dried in a vacuum oven at 80°C for 4 hours to obtain. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com