A kind of photopolymerizable photosensitive polymer material, preparation method and application thereof

A photosensitive polymer and photopolymerization technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of holographic image deformation color, poor quality of packaging materials, weak anti-counterfeiting, etc. Comprehensive performance enhancement, thickness reduction, and stability enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] As a preferred embodiment, the preparation method of the above-mentioned acrylate film-forming resin comprises the following steps:

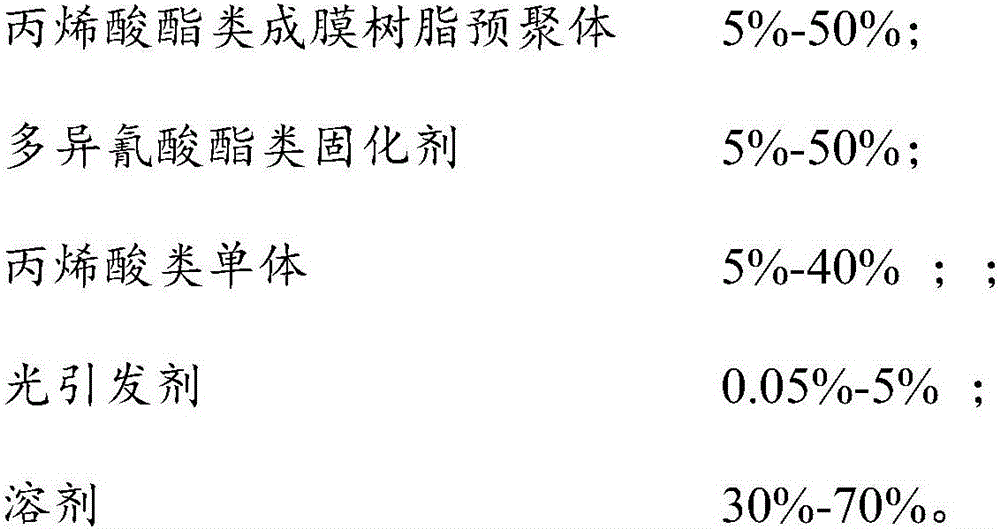

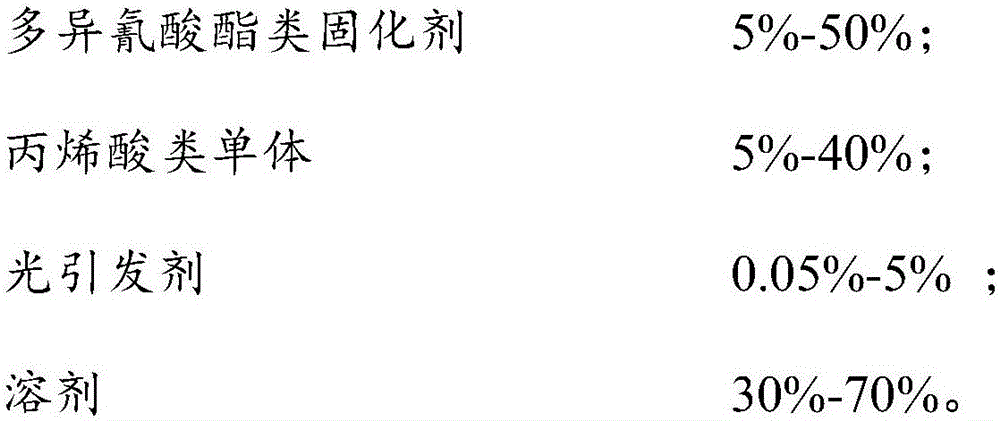

[0032] (1) Based on the calculation of 100% of the total weight of the above-mentioned acrylate film-forming resin prepolymer, take the following components by weight percentage:

[0033]

[0034] (2) Dissolving the weighed acrylate monomer and thermal initiator in the above solvent for reaction, then adding fluorine-containing acrylate monomer, and discharging to obtain acrylate film-forming resin prepolymer.

[0035] In the above step (1), the acrylate monomer should contain at least one acrylate hydroxy ester monomer, and the terminal hydroxyl group is used for polyurethane reaction with the isocyanate group of the subsequent polyisocyanate curing agent. Since the transmittance of the acrylate random copolymer is better, which is beneficial to the subsequent exposure of the photopolymerizable photosensitive polymer material, the acr...

Embodiment 1

[0070] A photopolymerizable photosensitive polymer material, which contains the following components by weight percentage:

[0071] Acrylic film-forming resin prepolymer 21.78%;

[0072] Polyisocyanate curing agent 12.03%;

[0073]2-Phenylphenoxyethyl acrylate 11.44%;

[0074] 4-cumylphenoxyethyl acrylate 6.64%;

[0075] Bis-2,6-difluoro-3-pyrrole phenyl titanocene 1.8%;

[0076] Butanone 46.31%.

[0077] And, prepare above-mentioned acrylate film-forming resin prepolymer by following two steps:

[0078] (1) Based on the calculation of 100% of the total weight of the above-mentioned acrylate film-forming resin prepolymer, take the following components by weight percentage:

[0079] Methyl methacrylate 11.2%;

[0080] Isooctyl methacrylate 7.9%;

[0081] Hydroxypropyl Acrylate 5.2%;

[0082] 2-(perfluorobutyl)ethyl methacrylate 11.7%

[0083] Azobisisobutyronitrile 4%;

[0084] Butanone 60%;

[0085] (2) Carry out free radical reaction with methyl methacrylate, isooc...

Embodiment 2

[0097] A photopolymerizable photosensitive polymer material, which contains the following components by weight percentage:

[0098] Acrylic film-forming resin prepolymer 14.56%;

[0099] Polyisocyanate curing agent 6.12%;

[0100] Ethoxylated bisphenol A dimethacrylate 10.78%;

[0101] 4-cumylphenoxyethyl acrylate 7.56%;

[0102] Chlorinated hexaarylbiimidazole 1.2%;

[0103] Butanone 59.78%.

[0104] This embodiment 2 is basically the same as the steps of preparing acrylate film-forming resin, polyisocyanate curing agent and photopolymerizable photosensitive polymer material in the above embodiment 1, the only difference is that polyether binary resin is used when preparing polyisocyanate curing agent Alcohol replaces the dihydric alcohol of the saturated alkane main chain as a chain extender, the high refractive index monomer is ethoxylated bisphenol A dimethacrylate and 4-cumylphenoxyethyl acrylate, and the photoinitiator is chlorinated bisphenol A imidazole.

[0105]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com