A kind of ibuprofen granule and preparation method thereof

A kind of particle and particle size range technology, which is applied in the field of ibuprofen granules and its preparation, can solve the problems of difficult to remove the pungent taste of granules, inaccurate dosage for patients, and poor patient compliance, so as to improve the pungent taste and eliminate the pungent taste. Taste, effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

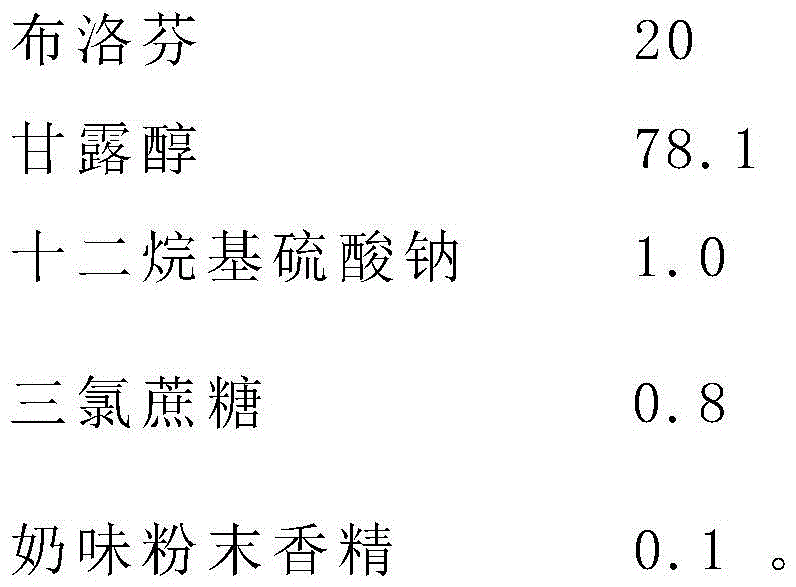

Embodiment 1

[0044]

[0045] Preparation:

[0046] A. said component is passed through 100 mesh sieve respectively, for subsequent use;

[0047] b. Configuration of the mixed liquid: Weigh the prescribed amount of sucralose, sodium lauryl sulfate and milk-flavored powder essence and dissolve in 30% ethanol solution, and stir until completely dissolved;

[0048] c. Mix the sieved ibuprofen and mannitol evenly, add the mixed solution prepared in step b, make a soft material, granulate through a 20-mesh sieve, dry for 6 hours below 55°C, and screen out 20-40 mesh The granules in between, i.e. ibuprofen granules, are divided into 1000 packets.

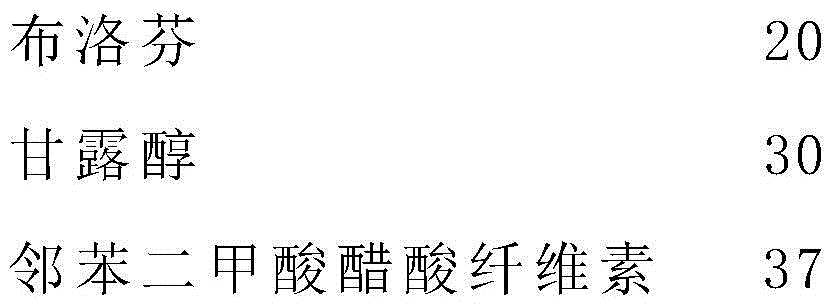

Embodiment 2

[0050]

[0051] Preparation method: prepared according to the method of Example 1.

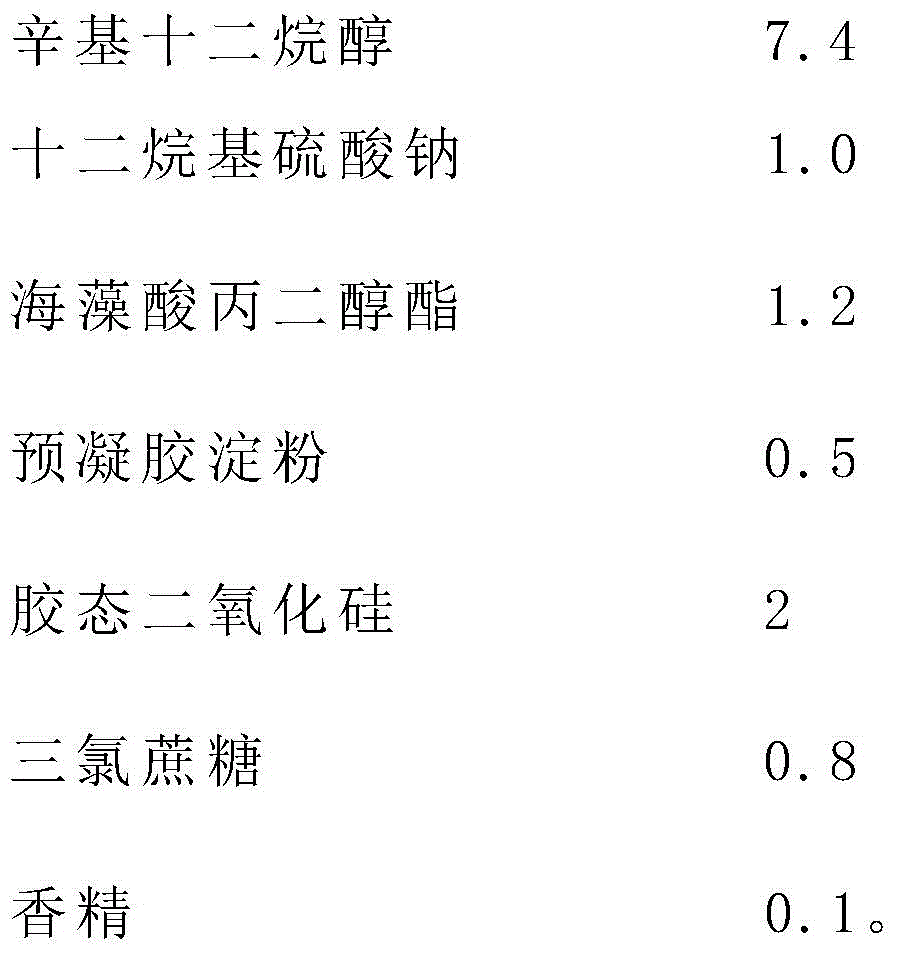

Embodiment 3

[0053]

[0054] Preparation:

[0055] 1) Preparation of ibuprofen microcapsules: add ibuprofen to cellulose acetate phthalate, add octyldodecanol while grinding, and grind evenly to obtain ibuprofen grinds; Add water at a volume ratio of 1:2 to obtain an aqueous solution; mix the ground ibuprofen and the aqueous solution evenly, and emulsify at high speed to obtain ibuprofen colostrum; place the ibuprofen colostrum in a high-pressure homogenizer Medium emulsification to obtain ibuprofen emulsion; the ibuprofen emulsion is ultrafinely pulverized and dried to obtain ibuprofen microcapsules with a particle size range of 5 μm and a yield of 95%;

[0056] 2) Configuration of the mixed solution: dissolve sodium lauryl sulfate in absolute ethanol, stir until completely dissolved, and obtain the mixed solution;

[0057] 3) adding the microcapsules prepared in step 1) to the mixed solution prepared in step 2), making a soft material, granulating through a 20-mesh sieve, spraying an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com