Lightweight aluminum-lithium alloy material and production method thereof.

A technology of aluminum-lithium alloy and production method, applied in the field of light-weight aluminum-lithium alloy material and its production, to achieve the effects of low cost, high specific strength and specific stiffness, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

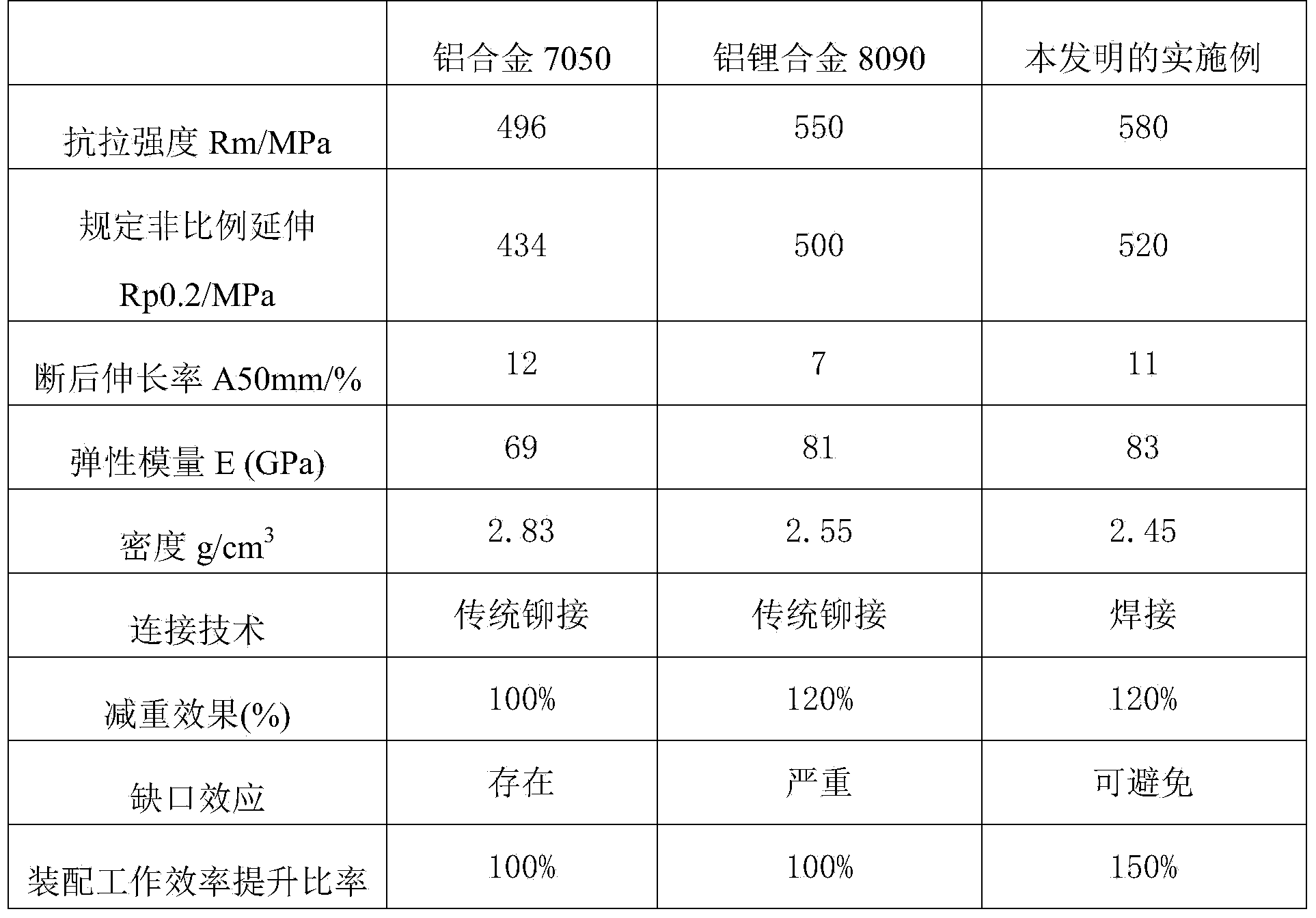

Embodiment 1

[0024] Embodiment 1, the preparation of aluminum-lithium alloy material of the present invention

[0025] Batching smelting: The mass ratio of the prepared metal raw materials is lithium 4wt%, copper: 3wt%, tin: 0.1wt%, zinc: 1.5wt%, lead: 0.05wt%, unavoidable impurities are less than or equal to 0.2wt%, and the remaining The amount is the ratio of aluminum into the melting furnace, the temperature of the melting furnace is 750 ° C, and the time is 2 hours.

[0026] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

[0027] Casting cold billet: adopt continuous casting method, use computer to control AC motor, realize micro-pitch reverse push process, produce large roll and heavy strip billet, mill the skin defects of strip billet through double-sided milling and milling unit, and pass through cold rolling mill , cut into rough round ingots with a diameter of 20-50mm and a length of 3-4 meters.

...

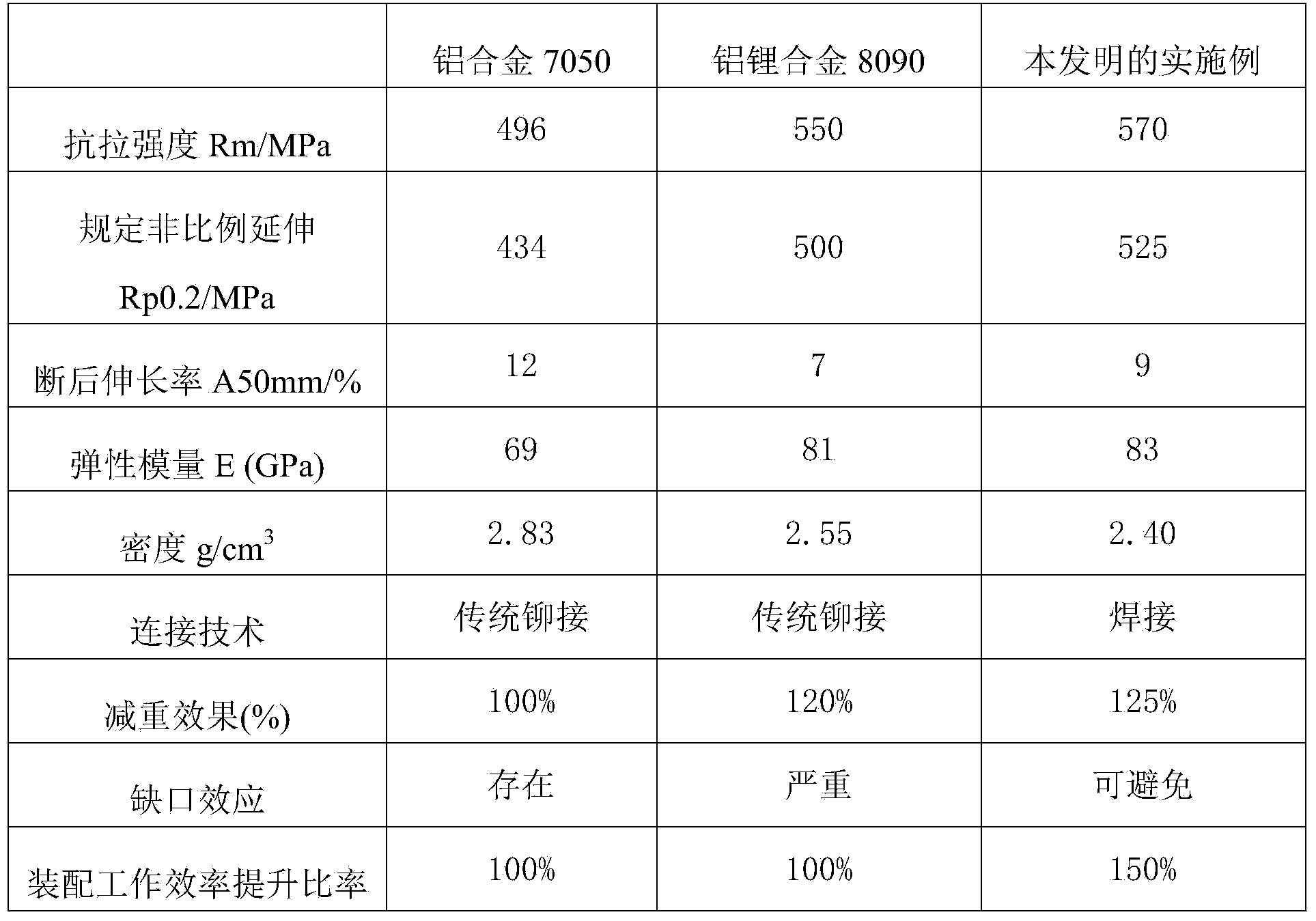

Embodiment 2

[0034] Embodiment 2, the preparation of aluminum-lithium alloy material of the present invention

[0035] Batching smelting: The mass ratio of the prepared metal raw materials is lithium 5wt%, copper: 1.5wt%, tin: 0.4wt%, zinc: 1wt%, lead: 0.05wt%, unavoidable impurities are less than or equal to 0.2wt%, and the remaining The ratio of the amount of aluminum is put into the smelting furnace, the temperature of the smelting furnace is 800° C., and the time is 1.5 hours.

[0036] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

[0037] Casting cold billet: adopt continuous casting method, use computer to control AC motor, realize micro-pitch reverse push process, produce large roll and heavy strip billet, mill the skin defects of strip billet through double-sided milling and milling unit, and pass through cold rolling mill , cut into rough round ingots with a diameter of 20-50mm and a length of 3-4 ...

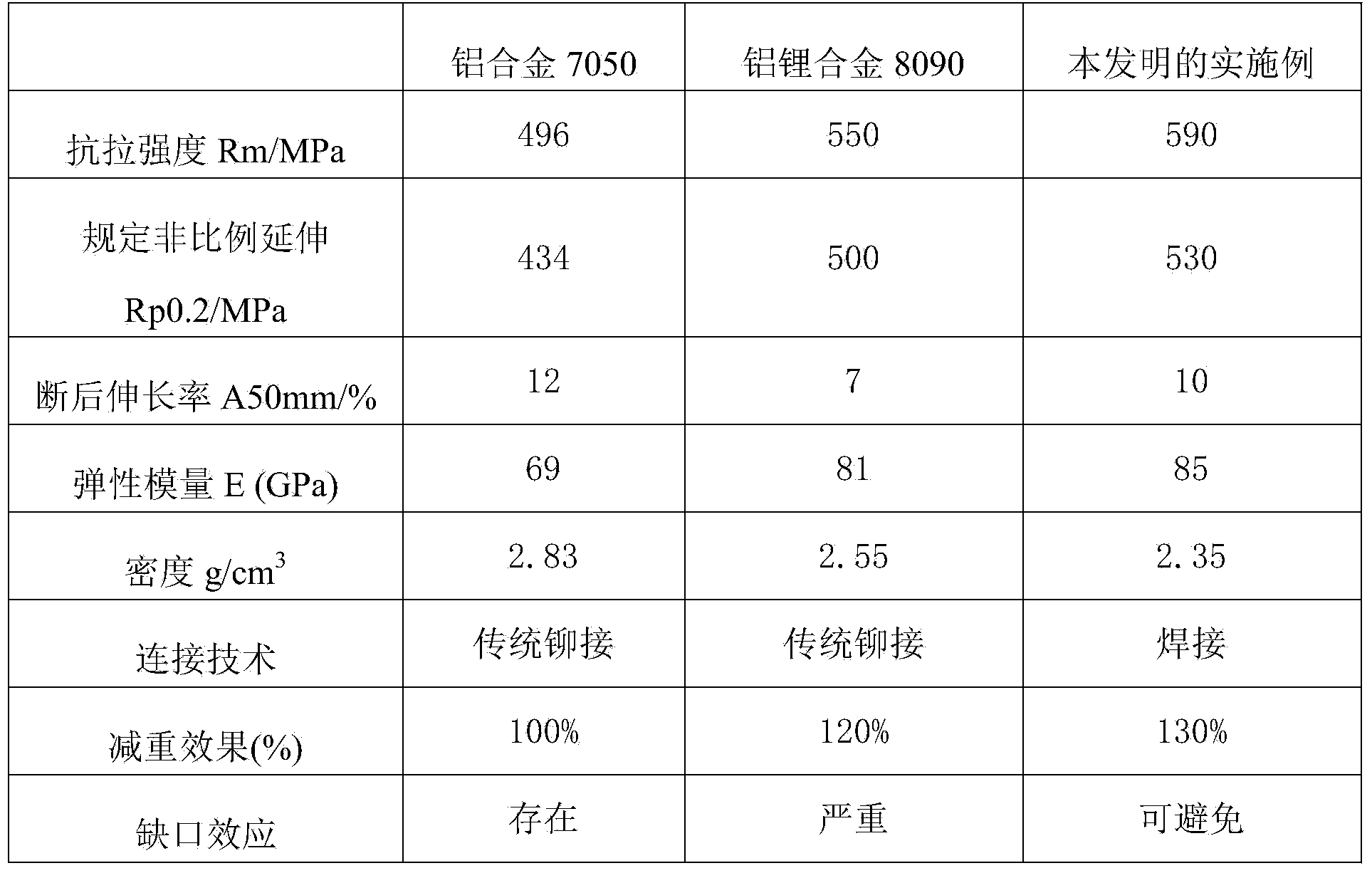

Embodiment 3

[0044] Embodiment 3, the preparation of aluminum-lithium alloy material of the present invention

[0045] Batch smelting: The mass ratio of the prepared metal raw materials is lithium 4.5wt%, copper: 2.5wt%, tin: 0.3wt%, zinc: 0.8wt%, lead: 0.75wt%, unavoidable impurities are less than or equal to 0.2wt% , the balance is the proportion of aluminum and put it into the melting furnace, the temperature of the melting furnace is 750 ℃, and the time is 1.5 hours.

[0046] Detection: Spectroscopic analysis is used to detect the smelted alloy liquid to ensure that its composition is within the range.

[0047] Casting cold billet: adopt continuous casting method, use computer to control AC motor, realize micro-pitch reverse push process, produce large roll and heavy strip billet, mill the skin defects of strip billet through double-sided milling and milling unit, and pass through cold rolling mill , cut into rough round ingots with a diameter of 20-50mm and a length of 3-4 meters.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com