Paint composition containing modified tung oil and preparation method thereof

A tung oil, modified technology, applied in the direction of coating, etc., can solve the problems of poor compatibility, insufficient bonding strength of cured coating, and affecting the application of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

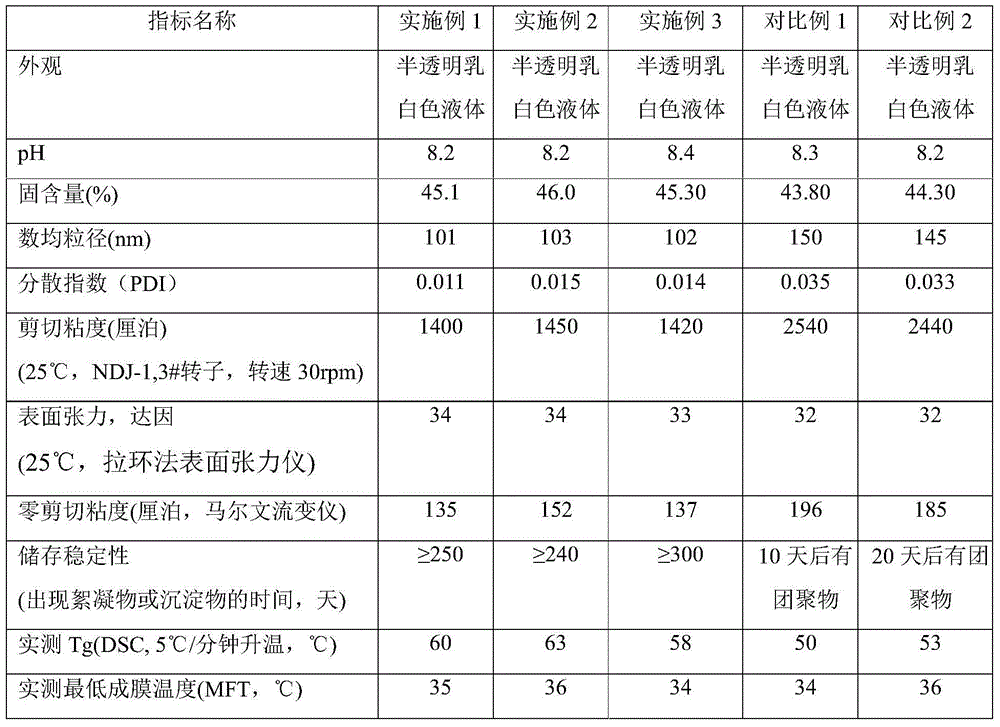

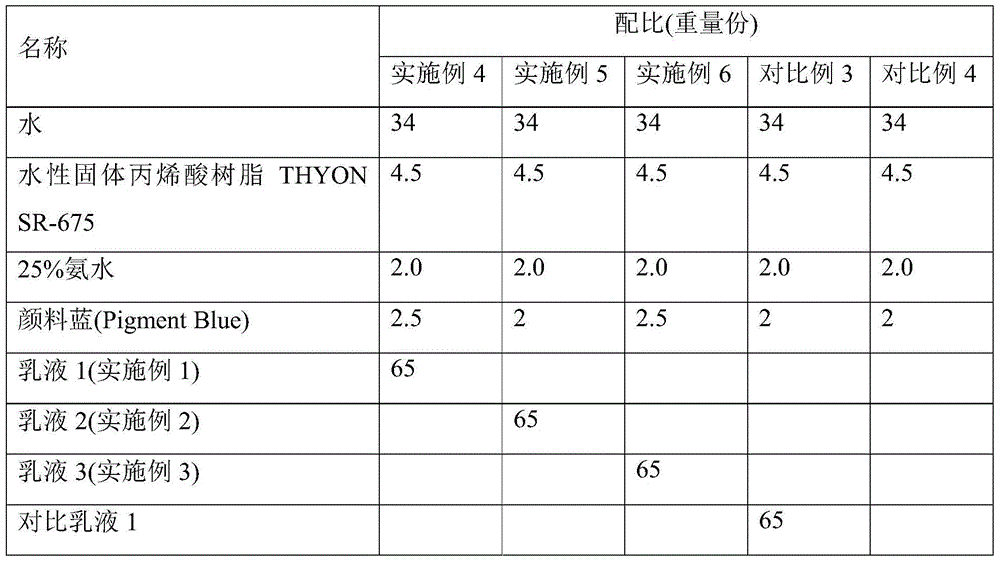

Examples

preparation example 1-

[0077] Preparation Example 1 - Preparation of Modified Tung Oil 1:

[0078] Refined tung oil (glyceride content 71wt%) and sodium maleic anhydride derivative sulfonate (sodium maleic anhydride derivative sulfonate, product name M12) were reacted at 140°C for 2 hours under nitrogen protection in a weight ratio of 100:70 to obtain addition Reaction product - modified tung oil 1.

preparation example 2-

[0079] Preparation Example 2 - Preparation of Modified Tung Oil 2:

[0080] Refine tung oil and 2-methyl-2-propene-1-sodium sulfonate (sodium2-methyl-2-propene-1-sulfonate (SMS)) according to the weight ratio of 100:80 under nitrogen protection at 150 ° C for 1.5 hours , to obtain the addition reaction product-modified tung oil 2.

preparation example 3-

[0081] Preparation Example 3 - Preparation of Modified Tung Oil 3:

[0082] Refined tung oil reacted with sodium allyl hydroxyalkyl sulfonate (SAHS) at a weight ratio of 100:80 at 140°C for 2 hours under nitrogen protection to obtain the addition reaction product - modified tung oil 3.

[0083] The auxiliary agent used in embodiment 1-3:

[0084] Ecosurf TM LF-45 surfactant: defoaming and wetting surfactant, without sulfonate group, produced by The Dow Chemical in the United States; name: Secondary Alcohol Alkoxylate (Secondary Alcohol Alkoxylate); main physical properties : Cloud Point (Cloud Point): 40-49; HLB: 12-13; Surface Tension: 31.5 Dynes, Pour Point: 6°C, Foam Height: 120 / 10; THYON SR-675: Waterborne solid acrylic resin, acid value 215, weight average molecular weight 9000, Tg 109°C, produced by Argentina DIRANSA Company;

[0085] COPS-1: reactive emulsifier, the registered trademark is Sipomer COPS-1, produced by Rhodia Company (English name: 1-Na, 1-allyloxy-2-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cloud point | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com