Single-component epoxy primer and preparation method thereof

An epoxy primer, one-component technology, applied in the field of coatings, can solve the problems of unstable ketimine structure, influence of coating storage period, insufficient stability, etc., and achieve strong corrosion resistance, long storage period and flexibility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

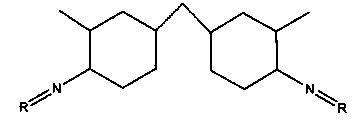

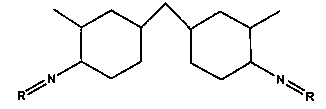

[0042] 1) Add 200g of 3,3-dimethyl-4,4-diaminodicyclohexylmethane (DMDC) and 400g of cyclohexanone to a three-necked flask equipped with a thermometer, a glass stopper, and a water separator respectively, When heated to 140°C, the water produced by the reaction boils with cyclohexanone, and enters the water separator to separate from the reaction system. After continuing to stir and react for 3 hours, the excess ketone is distilled off under reduced pressure, cooled, and sealed for use.

[0043] 2) Dissolve 100g of epoxy resin E44 into 30g of solvent, add 2g of gas phase SiO 2 , heated to 50°C to dissolve, stirred at 3000r / min for 10min, then added rutile SiO 2 20g, 20g of mica iron oxide, 5g of mica powder, 3g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 2g of dispersant, 0.5g of leveling agent, 0.5g of defoamer, etc., in Stir at 2000r / min for 20min, finally add 30g of the ketimine curing agent prepared above, stir at 2000r / min for 5min, and seal the package. Take out pa...

Embodiment 2

[0047] Other reactions are the same as in Example 1, except that cyclohexanone is changed to 2,4-tetramethyl-3-pentanone in the first) reaction. Test performance.

Embodiment 3

[0049] Other reactions are the same as in Example 1, except that in the second) reaction, the epoxy resin E44 is changed to bisphenol F type epoxy resin with an epoxy value of 0.42-0.48.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com