Method for preparing manganese-iron alloy based on low-grade manganese ore

A low-grade manganese ore and ferromanganese alloy technology, applied in the field of metallurgy, can solve the problems of environmental pollution, high energy consumption, large investment, etc., and achieve the effect of simple and controllable method, high metal yield and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

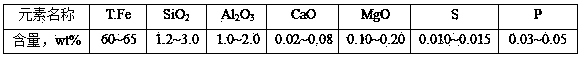

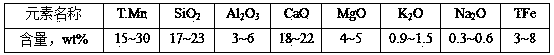

[0030] A method for preparing ferromanganese alloy based on low-grade manganese ore, specifically comprising the following steps: taking manganese ore within the composition range of Table 1, the main components are: T.Mn 20.5%, SiO 2 18.7%, CaO 19.4%, T.Fe 5.3%; take the iron ore powder within the composition range of Table 2, the main components are: T.Fe 62.5%, SiO 2 1.5%, Al 2 o 3 1.3%. The above-mentioned low-grade manganese ore and iron ore powder (the mass ratio of the two is 2:1) are mixed, crushed, ball milled, and passed through a 180-mesh sieve to obtain the oversize and undersize. Weigh 5kg of undersieve, add 0.25kg of quicklime, 1.0kg of coal powder, 0.1kg of bentonite and 0.4kg of water to make pellets on a disc pelletizer. The diameter of the green pellets is 10mm. Dry the pellets in an oven at 105°C for 4 hours. Then put the dried pellets into a graphite crucible, reduce them at 1450°C for 15 minutes, cool with the furnace, use a jaw crusher to crush the ...

Embodiment 2

[0032] A method for preparing ferromanganese alloys based on low-grade manganese ore, specifically comprising the following steps: taking manganese ore within the composition range of Table 1, the main components are: T.Mn 24.6%, SiO 2 20.7%, CaO 20.1%, T.Fe 6.2%; take the iron ore powder within the composition range of Table 2, the main components are: T.Fe 63.2%, SiO 2 2.7%, Al 2 o 3 1.6%. The above-mentioned low-grade manganese ore and iron ore powder (the mass ratio of the two is 3:1) are mixed, crushed, ball milled, and passed through a 200-mesh sieve to obtain the oversize and undersize. Weigh 8kg of undersieve, add 0.4kg of quicklime, 2.4kg of coal powder, 0.2kg of bentonite and 0.7kg of water to make pellets on a disc pelletizer. The diameter of the green pellets is 16mm. Dry the pellets in an oven at 105°C for 4 hours. Then put the dried pellets into a graphite crucible, reduce at 1500°C for 10 minutes, cool with the furnace, crush the reduced pellets with a jaw...

Embodiment 3

[0034] A method for preparing ferromanganese alloy based on low-grade manganese ore, specifically comprising the following steps: taking manganese ore within the composition range of Table 1, the main components are: T.Mn 28.2%, SiO 2 19.2%, CaO 18.6%, T.Fe 7.1%; take the iron ore powder within the composition range of Table 2, the main components are: T.Fe 64.1%, SiO 2 2.4%, Al 2 o 3 1.8%. The above-mentioned low-grade manganese ore and iron ore powder (the mass ratio of the two is 4:1) are mixed, crushed, ball milled, and passed through a 250-mesh sieve to obtain the oversize and undersize. Weigh 10kg of the undersieve, add 0.6kg of quicklime, 2.5kg of coal powder, 0.3kg of bentonite and 0.8kg of water to make pellets on a disc pelletizer. The diameter of the green pellets is 10mm. Dry the pellets in an oven at 105°C for 4 hours. Then put the dried pellets into a graphite crucible, reduce them at 1500°C for 10 minutes, cool with the furnace, crush the reduced pellets w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com