Differential separation and upgrading method for feldspar minerals

A differentiated, feldspar technology, applied in the field of comprehensive utilization of resources, can solve the problems of large difference in quality, poor particle size of feldspar, ignoring the natural inhomogeneity of feldspar minerals, etc., to achieve good product quality, high recovery rate, The effect of increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

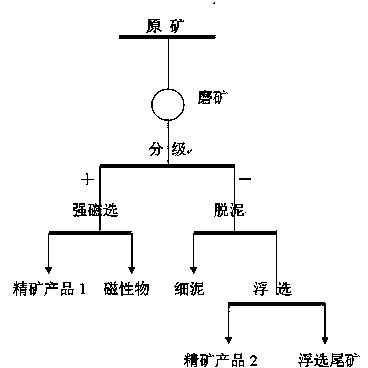

Image

Examples

Embodiment 1

[0011] A feldspar mine in Yiyang, Henan Province, the main minerals in the ore are microplagioclase, plagioclase, albite, quartz and mica minerals, the main metal minerals are limonite, hematite, etc. Ferrous (Fe 2 o 3 ) content of 0.71%.

[0012] (1) Take 300 grams of stone-2mm feldspar raw ore for grinding. The fineness of the ground product (-200 mesh content) is about 35%. It is sieved with a 150-mesh standard sieve, and the yield on the sieve is 48.27%. Sieve product Fe 2 o 3 The content is 0.32%, the under-sieve yield rate is 51.73%, and the under-sieve product Fe 2 o 3 The content is 1.02%.

[0013] (2) For +150-mesh samples, the slon pulsating high-gradient strong magnetic separator is used for magnetic separation to remove iron, and the operating yield is 96%, Fe 2 o 3 Feldspar concentrate products with a content of 0.13%.

[0014] (3) For -150 mesh samples, the fine mud is removed by hydraulic classification, and 075L flotation tank is used for flotation. Un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com