Construction waste environmental protection comprehensive treatment system and its treatment method

A comprehensive treatment and construction waste technology, applied in the direction of construction waste recycling, solid waste removal, recycling technology, etc., can solve the problems of noise affecting dust, sorting personnel health damage, low efficiency, etc., to achieve reasonable material sorting, The effect of high degree of automation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

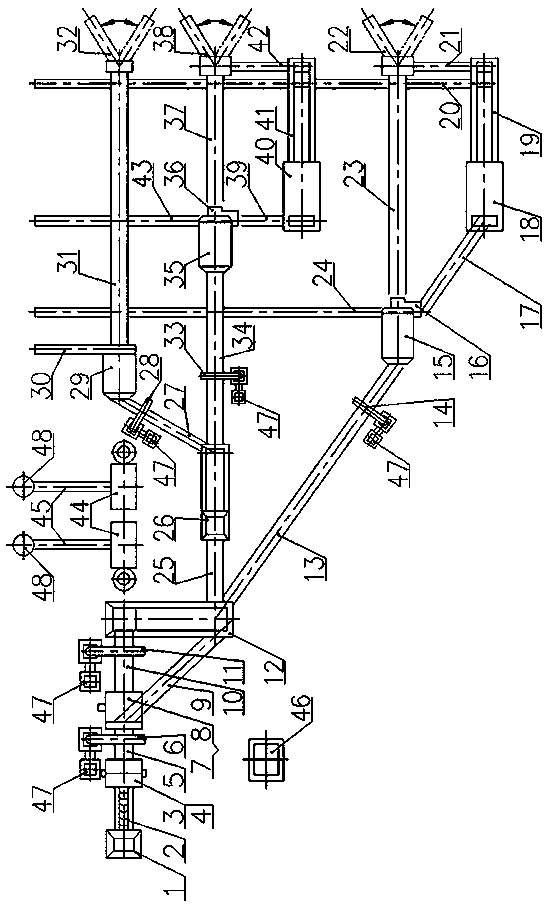

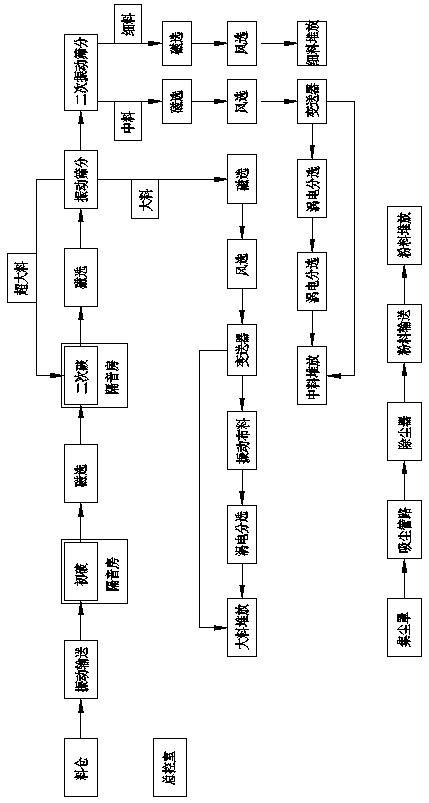

[0053] see Figure 1-Figure 2 , a construction waste environmental protection comprehensive processing system that the present invention relates to, it comprises silo 1, vibrating conveyor 2, primary crusher 3, primary crusher soundproof room 4, primary crushing conveyor 5, magnetic separator I 6, Secondary Crusher 7, Secondary Crusher Soundproof Room 8, Oversized Material Conveyor 9, Secondary Crushing Conveyor 10, Magnetic Separator Ⅱ 11, Vibrating Screening Machine 12, Large Material Conveyor Ⅰ 13, Magnetic Separator Ⅲ 14 , wind separator Ⅰ 15, transmitter Ⅰ 16, large material conveyor Ⅲ 17, large material vibrating distribution machine 18, large material eddy current separator 19, non-ferrous metal conveyor 20, large material conveyor Ⅳ 21, large Material stacker 22, large material conveyor II 23, light material conveyor I 24, medium and fine material conveyor 25, secondary vibration screening machine 26, fine material conveyor I 27, magnetic separator IV 28, wind separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com