Multi-stage quick energy-saving garbage sorting system

A sorting and rapid technology, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of low utilization rate of equipment, waste of resources, small processing capacity, etc., achieve reasonable structure layout, reduce energy consumption, and improve work efficiency efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

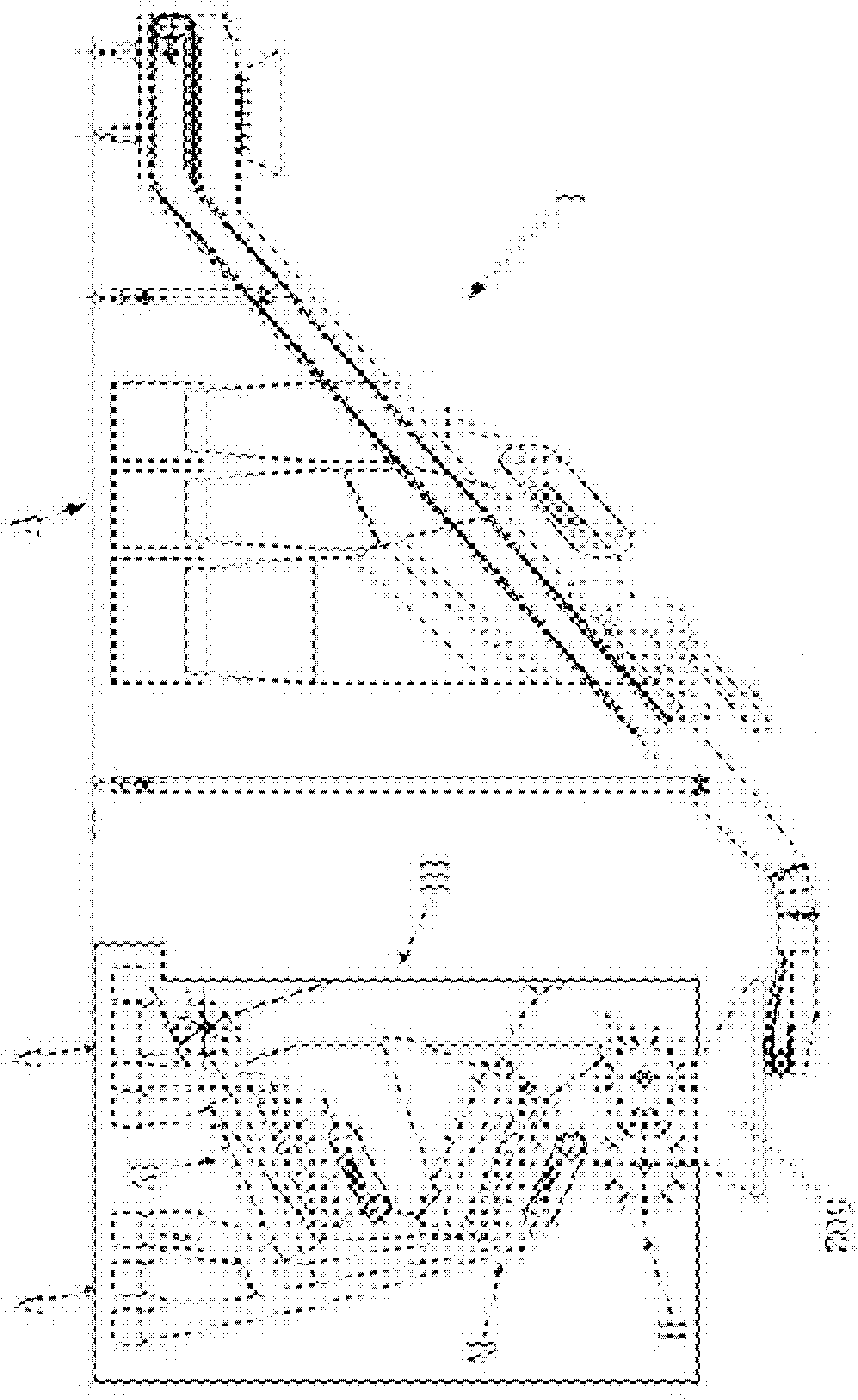

[0045] Such as figure 1 As shown, the present invention includes a feeding mechanism I, a drum bag breaking mechanism II, a plastic cloth sorting device III, a screening and raking mechanism IV, and a collection mechanism V, etc.; wherein, the discharge end of the feeding mechanism I is located at the drum breaking above the bag mechanism II; the screening and raking mechanism IV is located under and / or under the side of the drum bag breaking mechanism II; the plastic cloth sorting device III is located under and / or under the side of the drum breaking mechanism II; One side of the mechanism IV; the collecting mechanism V is respectively located under and / or under the side of the feeding mechanism I, the plastic cloth sorting device III and the screening and raking mechanism IV. The collecting mechanism V includes several material collectors 501 .

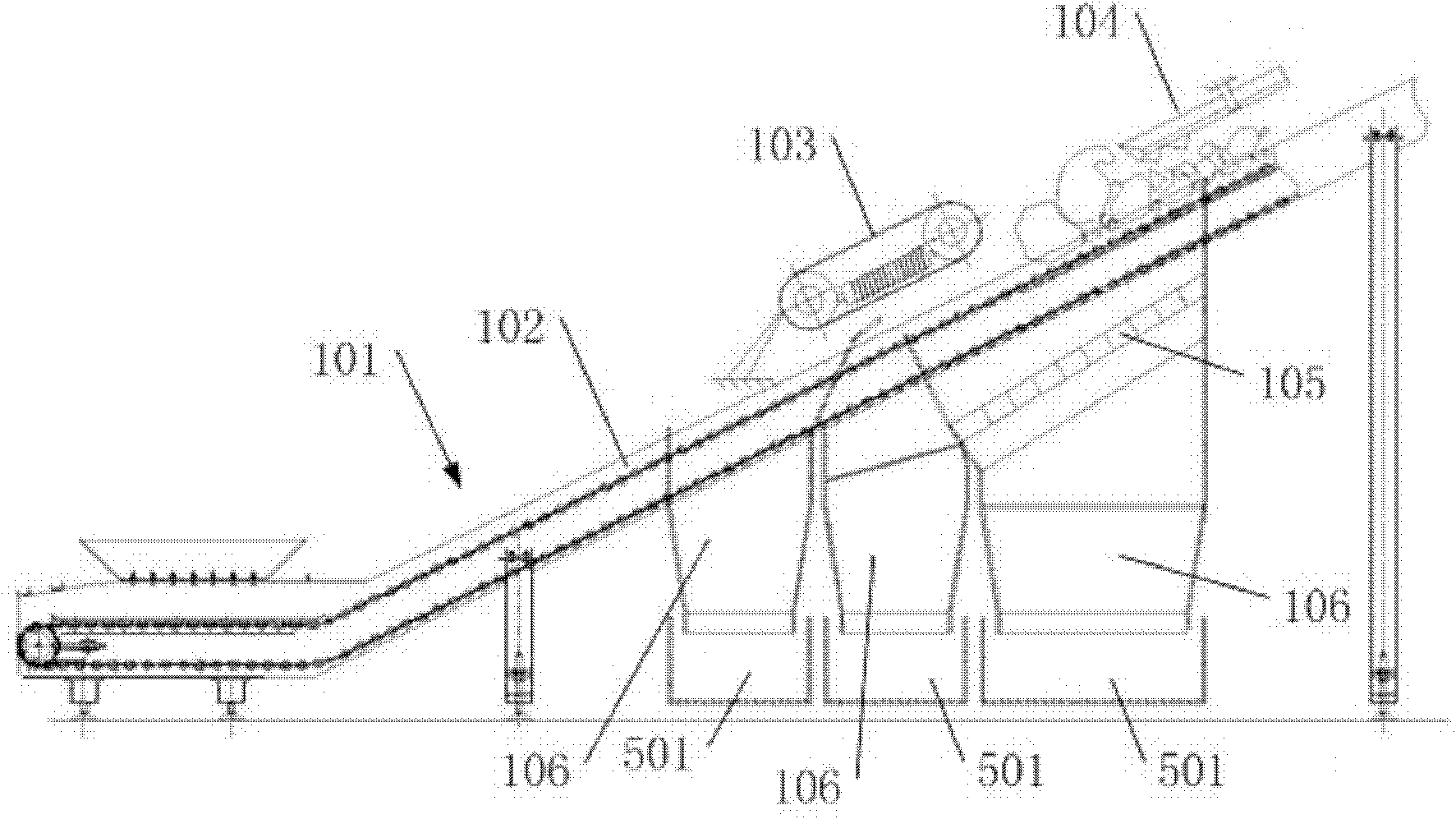

[0046] Such as figure 2 As shown, the feeding mechanism I includes a feeding device 101, a material separation device 104, a ma...

Embodiment 2

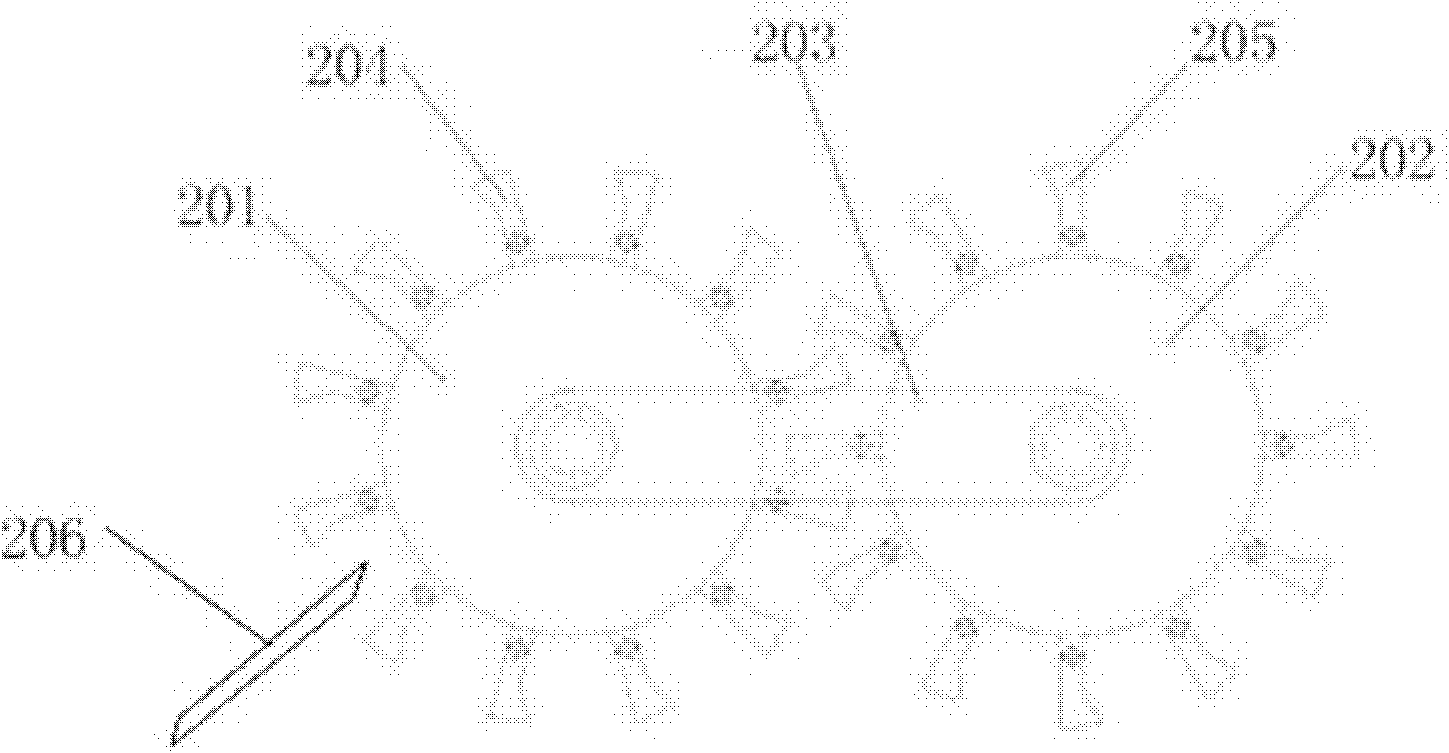

[0062] Such as Figure 4 As shown, the plastic cloth sorting device III includes a material collection tank 302 , a material dumping and turning device 301 , a material turning and sorting device 303 and a screening and sorting device 305 . The material collecting tank 302 is arranged below the unloader A206. The material dumper 301 is arranged on the upper part of the material collection tank 302 and below the unloader A206. The material turning and sorting device 303 is arranged at the outlet of the material collection tank 302; the material turning and sorting device 303 is provided with an unloader B304. The screening and sorting device 305 is arranged below the material turning and sorting device 303, and the screening and sorting device 305 is arranged obliquely, and its inclination angle is 30°-70°. Material collectors 501 are respectively arranged below the screening device 305 and at the outlet of the screen surface.

[0063] Others are the same as embodiment 1.

Embodiment 3

[0065] Such as Figure 11 As shown, the screening and raking mechanism IV includes a rolling rake sorting device 402 and a screening and conveying device 403 . The screening and conveying device 403 is located below and / or below the roller rake sorting device 402 . The roller rake sorting device 402 is located below the bag breaking drum 202 . A circular screening mechanism is arranged under and / or under the sides of the screening and raking mechanism IV.

[0066] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com