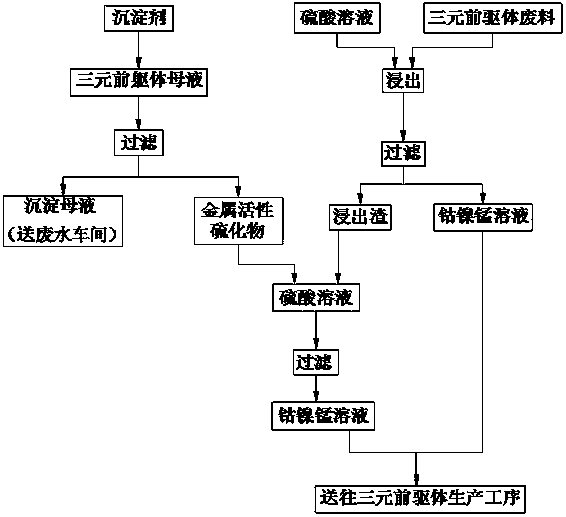

Waste recovery process in production process of nickel-cobalt-manganese ternary precursor

A production process, nickel-cobalt-manganese technology, which is applied in the field of nickel-cobalt-manganese ternary precursor waste recycling, can solve the problems of strict environmental protection requirements and danger, and achieve the goal of reducing the cost of impurity removal, less control points, and reasonable wastewater Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Based on the above description, the following specific examples are provided: For example, the main content of nickel-cobalt-manganese ternary precursor waste: Co 12.19%; Ni 31.48%; Mn 18.33%;

[0029] Step 1: Use sodium sulfide to precipitate and recover the valuable metals in the mother liquor of the nickel-cobalt-manganese ternary precursor production process. The content of metal sulfide after precipitation: Co 0.3%; Ni 12.66%; Mn 12.32%;

[0030] Step 2: Use 1.25mol / L sulfuric acid solution to carry out acid-dissolution leaching of the nickel-cobalt-manganese ternary precursor waste, the liquid-solid ratio is 5:1, the reaction temperature is 90°C, and the reaction time is 4h; the leaching residue is ready for use; the filtrate is sent as a product solution To the ternary precursor precipitation process to produce precursor products, the main content of nickel-cobalt-manganese solution: Co 19.85g / L; Ni 52.73g / L; Mn 0.004g / L; PH=1.13;

[0031] Step 3: Weigh the leach...

Embodiment 2

[0034] Provide the recovery process of nickel-cobalt-manganese ternary precursor waste such as the main content: Co 12.19%; Ni 31.48%; Mn 18.33%:

[0035] Step 1: Use sodium sulfide to precipitate and recover the valuable metals in the mother liquor of the nickel-cobalt-manganese ternary precursor production process. The content of metal sulfide after precipitation: Co 0.3%; Ni 12.66%; Mn 12.32%;

[0036] Step 2: Use 1.25mol / L sulfuric acid solution to carry out acid-dissolution leaching of the nickel-cobalt-manganese ternary precursor waste, the liquid-solid ratio is 5:1, the reaction temperature is 90°C, and the reaction time is 4h; the leaching residue is ready for use; the filtrate is sent as a product solution To the ternary precursor precipitation process to produce precursor products, the main content of nickel-cobalt-manganese solution: Co 19.85g / L; Ni 52.73g / L; Mn 0.004g / L; PH=1.13;

[0037]Step 3: Weigh the leaching slag and metal sulfide from step 2, and the weighin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com