A kind of wide potential window negative electrode material, its preparation method and application

A negative electrode material and potential technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems that are not conducive to large-scale industrial production, complex and changeable processes, and excessive energy consumption, and achieve considerable reversible capacity and good dispersion , The effect of stabilizing the cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

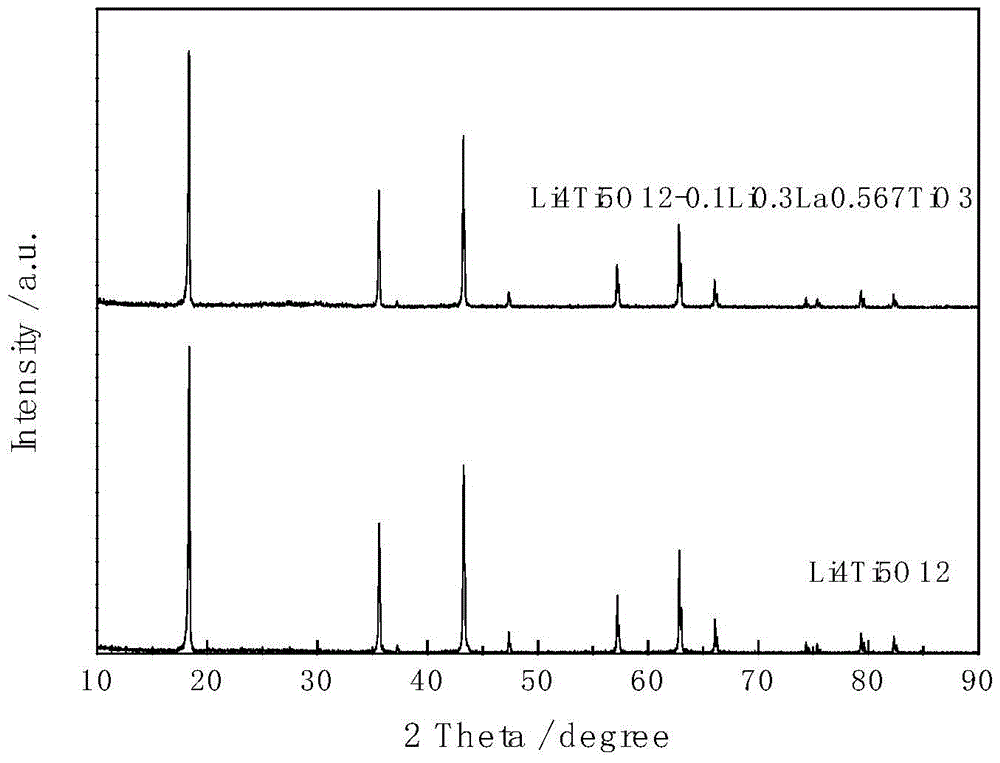

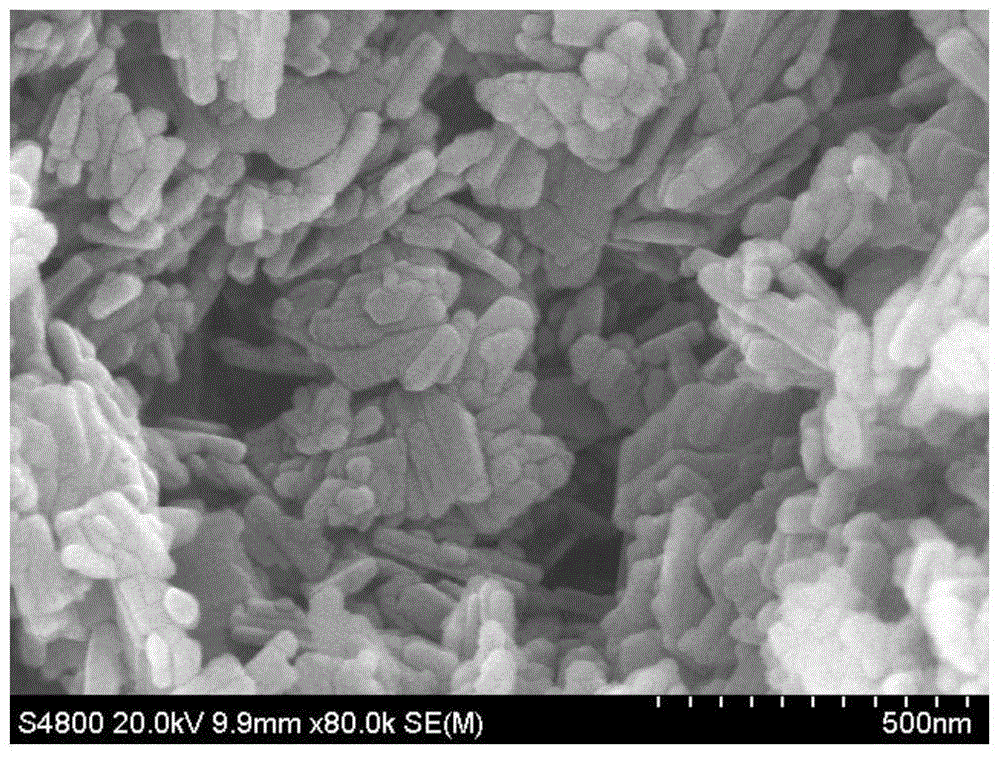

[0026] Put 0.009mol of lithium hydroxide and 0.01mol of tetrabutyl titanate in a beaker filled with 50mL of ethylene glycol, and stir for 12h under sealed conditions. will be 5.67×10 -4 mol lanthanum acetate, 0.001mol tetrabutyl titanate and 3×10 -4 mol lithium acetate was mixed in a beaker and stirred for 12 hours under sealed conditions. After stirring, mix the above two solutions, add 50mL of deionized water, stir vigorously for 1min, transfer to a 200mL closed reaction kettle and keep warm at 180°C for 36h. After cooling, filter with suction and dry at 80°C for 12h. The resulting mixture was put into a muffle furnace, calcined at 600 °C for 6 h, and cooled to room temperature to obtain Li 4 Ti 5 o 12 -0.1Li 0.3 La 0.567 TiO 3 composite material. X-ray powder diffraction analysis indicated that the obtained composite had Li 4 Ti 5 o 12 structure, with a small amount of impurity peaks and high crystallinity. From scanning electron microscope analysis, it is know...

Embodiment 2

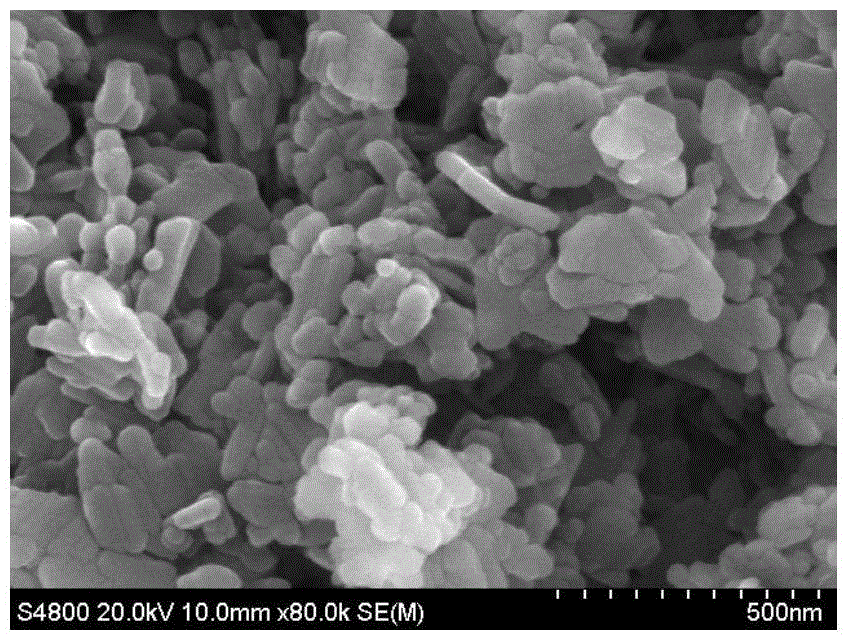

[0028] Put 0.009mol of lithium hydroxide and 0.01mol of tetrabutyl titanate in a beaker filled with 50mL of ethylene glycol, and stir for 14h under sealed conditions. will be 2.835×10 -4 mol lanthanum nitrate, 5×10 -4 mol tetrabutyl titanate and 1.5×10 -4 mol lithium hydroxide was mixed in a beaker and stirred for 12 hours under sealed conditions. After stirring, mix the above two solutions, add 50mL of deionized water, stir vigorously for 1min, transfer to a 200mL airtight reaction kettle and keep warm at 180°C for 30h. After cooling, filter with suction and dry at 100°C for 16h. The resulting mixture was put into a muffle furnace, calcined at 500 °C for 8 h, and cooled to room temperature to obtain Li 4 Ti 5 o 12 -0.05Li 0.3 La 0.567 TiO 3 composite material. X-ray powder diffraction analysis indicated that the obtained composite had Li 4 Ti 5 o 12structure with high crystallinity. From scanning electron microscope analysis, it is known that the particle size o...

Embodiment 3

[0030] Put 0.009mol of lithium hydroxide and 0.01mol of tetrabutyl titanate in a beaker filled with 50mL of ethanol, and stir for 12h under sealed conditions. will be 5.67×10 -4 mol lanthanum acetate, 0.001mol tetrabutyl titanate and 3×10 -4 mol lithium acetate was mixed in a beaker and stirred for 12 hours under sealed conditions. After stirring, mix the above two solutions, add 50mL of deionized water, stir vigorously for 1min, transfer to a 200mL closed reaction kettle and keep warm at 170°C for 40h. After cooling, filter with suction and dry at 90°C for 18h. The resulting mixture was put into a muffle furnace, calcined at 600 °C for 10 h, and cooled to room temperature to obtain Li 4 Ti 5 o 12 -0.1Li 0.3 La 0.567 TiO 3 composite material. X-ray powder diffraction analysis indicated that the obtained composite had Li 4 Ti 5 o 12 structure, with a small amount of impurity peaks and high crystallinity. According to scanning electron microscope analysis, the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com