Preparation method of few-layer bismuth selenide nanosheets

A nano-sheet and a few-layer technology, applied in the field of bismuth selenide bulk materials, can solve the problems of cumbersome, unsuitable for mass production, large consumption, etc., and achieve the effect of good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

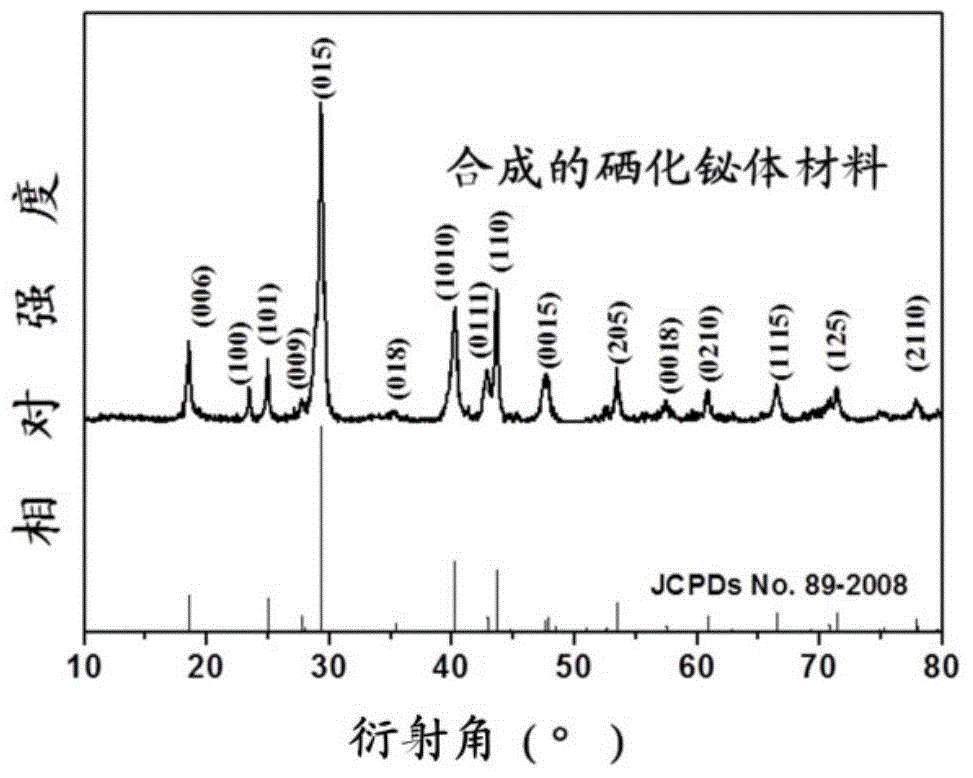

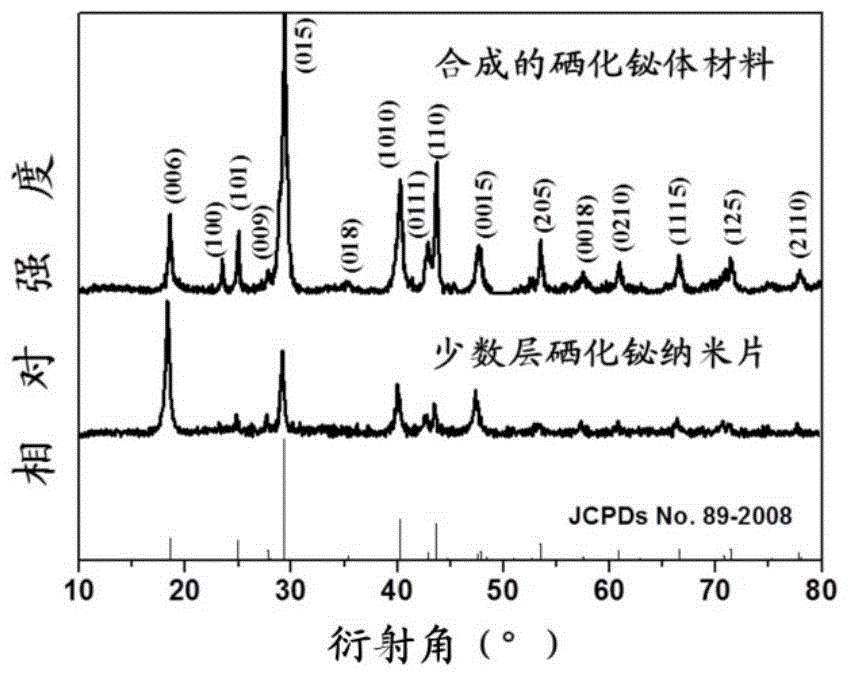

[0025] Bi 2 Se 3 Preparation of solid materials: Weigh 0.9g polyvinylpyrrolidone with an electronic balance and dissolve it in a beaker containing 36mL of ethylene glycol. In addition, 1mmol of bismuth oxide, 3mmol of selenium powder and 4mmol of ethylenediaminetetraacetic acid are added to the above solution. Stir well to mix. Pour the mixed solution into a high-pressure reactor and seal it, then place it in a homogeneous reactor and raise the temperature to 200°C, and react at 200°C for 20 hours to make the reaction complete. The obtained mixed solution was processed by high-speed centrifugation, the supernatant was removed, washed twice with ultrapure water and absolute ethanol respectively, and finally dried in a vacuum oven at 60° C. for 96 hours.

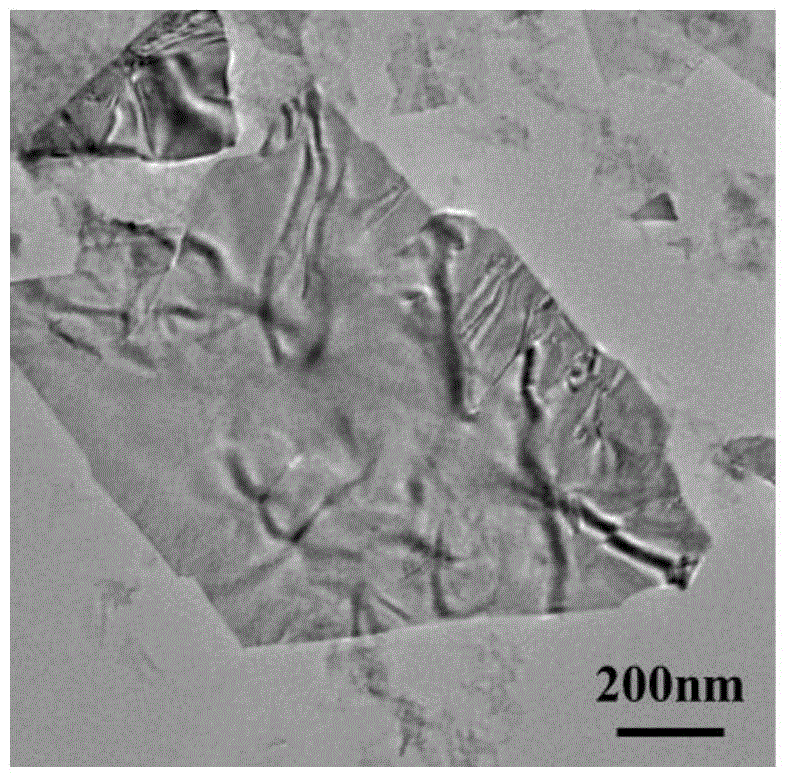

[0026] Fabrication of few-layer bismuth selenide nanosheets using NMP: to synthesize Bi 2 Se 3 Powder as raw material, 50mg, finely ground Bi 2 Se 3 The powder was added into 50mL of NMP, and then the mixed system was ul...

Embodiment 2

[0036] Bi 2 Se 3 Preparation of solid materials: Weigh 0.9g polyvinylpyrrolidone with an electronic balance and dissolve it in a beaker containing 36ml ethylene glycol. In addition, 1mmol bismuth oxide, 3mmol selenium powder and 4mmol ethylenediaminetetraacetic acid are added to the above solution respectively. Stir well to mix. Pour the mixed solution into a high-pressure reactor and seal it, then place it in a homogeneous reactor and raise the temperature to 200°C, and react at 200°C for 20 hours to make the reaction complete. The obtained mixed solution was processed by high-speed centrifugation, the supernatant was removed, washed twice with ultrapure water and absolute ethanol respectively, and finally dried in a vacuum oven at 60° C. for 96 hours.

[0037] Few-layer bismuth selenide nanosheets using CS-HAc: to synthesize Bi 2 Se 3 Powder as raw material, 50mg, finely ground Bi 2 Se 3 The powder was added to 50 mL of acetic acid aqueous solution with a chitosan conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com