A kind of monolithic palladium catalyst and its preparation method and application

A palladium catalyst, packaged technology, applied in the direction of carbon monoxide or formate reaction preparation, catalyst carrier, chemical instrument and method, etc., can solve the problems of poor thermal conductivity of alumina, expensive catalyst cost, overheating reaction of reactor, etc. , to achieve the effect of stable structure, easy molding and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

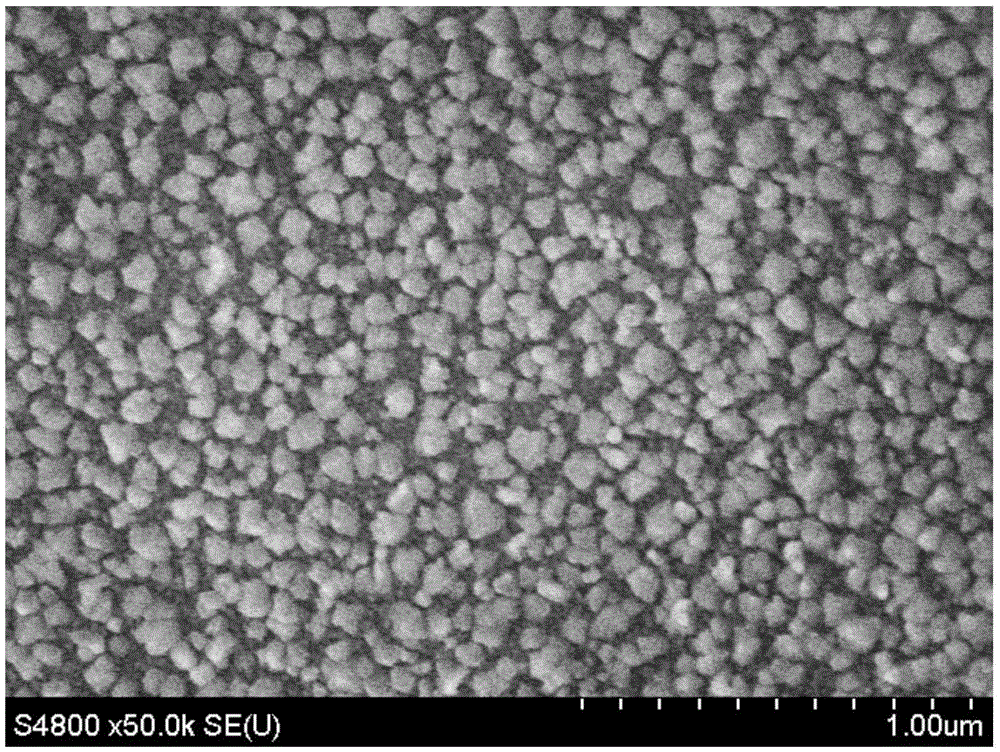

Image

Examples

Embodiment 1

[0046] 1. Weigh 5 grams of nickel foam, add 0.3 grams of aluminum powder with a particle size of 1 to 3 microns (the mass ratio of aluminum powder / metal carrier is 6 / 100) to impregnate in equal volume, then dry, and then Carry out solid-solid alloying reaction (about 2 hours) at 600°C in a high-purity protective atmosphere to obtain a metal phase skeleton after alloying treatment;

[0047] 2. The alloyed metal phase skeleton obtained in step 1 is subjected to an aluminum extraction reaction at room temperature to 60° C. with an aqueous solution of sodium hydroxide with a concentration of 15 wt % for 1 hour, rinsed with distilled water, dried, and placed in the Calcined in the air at 450°C for 2 hours to obtain a porous metal phase support for anchoring oxides, expressed as NiO-Ni-foam;

[0048] 3. Weigh 5 grams of the metal phase carrier prepared in step 2, and use Pd(NO 3 ) 2 The aqueous solution is impregnated with an equal volume at room temperature, and after drying, it ...

Embodiment 2

[0056] 1, with the step 1 of embodiment 1;

[0057] 2. The alloyed metal phase skeleton obtained in step 1 is subjected to an aluminum extraction reaction at room temperature to 60° C. with an aqueous solution of sodium hydroxide with a concentration of 15 wt % for 1 hour, rinsed with distilled water, dried, and placed in the Calcined in the air at 550°C for 2 hours to obtain a porous metal phase support for anchoring oxides, expressed as NiO-Ni-foam;

[0058] 3. Weigh 5 grams of the metal phase carrier prepared in step 2, and use palladium nitrate containing 0.025 gram of Pd, 0.125 gram of CeO 2 of cerium nitrate and 0.125 g of Al 2 o 3 The mixed aqueous solution of aluminum nitrate is impregnated with an equal volume at room temperature, and after drying, it is baked in the air at 500°C for 2 hours to obtain a palladium-ceria-alumina monolithic structure supported on a nickel foam carrier anchored by NiO. palladium catalyst.

[0059] It is determined by plasma inductivel...

Embodiment 3

[0064] a. Weigh 5 grams of sintered aluminum fiber (fiber diameter: 50 microns) sheet, carry out aluminum extraction reaction with 1% sodium hydroxide aqueous solution for 1 hour, rinse with distilled water, dry, and roast in air at 300°C After 2 hours, the metal phase support of the porous anchored oxide was obtained, expressed as Al 2 o 3 -Al50-SMF;

[0065] b, take by weighing 5 grams of the metal phase support that step a makes, use the Pd(Ac) that contains 0.025 gram of Pd 2 Aqueous solution, impregnated with equal volume at room temperature, after drying, baked in air at 400°C for 2 hours to obtain anchored Al 2 o 3 A monolithic palladium catalyst supported by palladium on a sintered aluminum fiber support.

[0066] It is known through plasma inductively coupled atomic emission spectrometry that: in the catalyst prepared in this embodiment, the mass content of Pd is 0.46%; through temperature-programmed reduction analysis and measurement, in the catalyst prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com