Method for extracting high-quality iron powder and borax from paigeite

A technology of boron ore and boron concentrate, applied in chemical instruments and methods, borates, boron oxides, etc., can solve the problems of poor boron activity, high energy consumption, and difficult separation of boron and iron, so as to improve the additional Value, reduce evaporation, increase the effect of crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

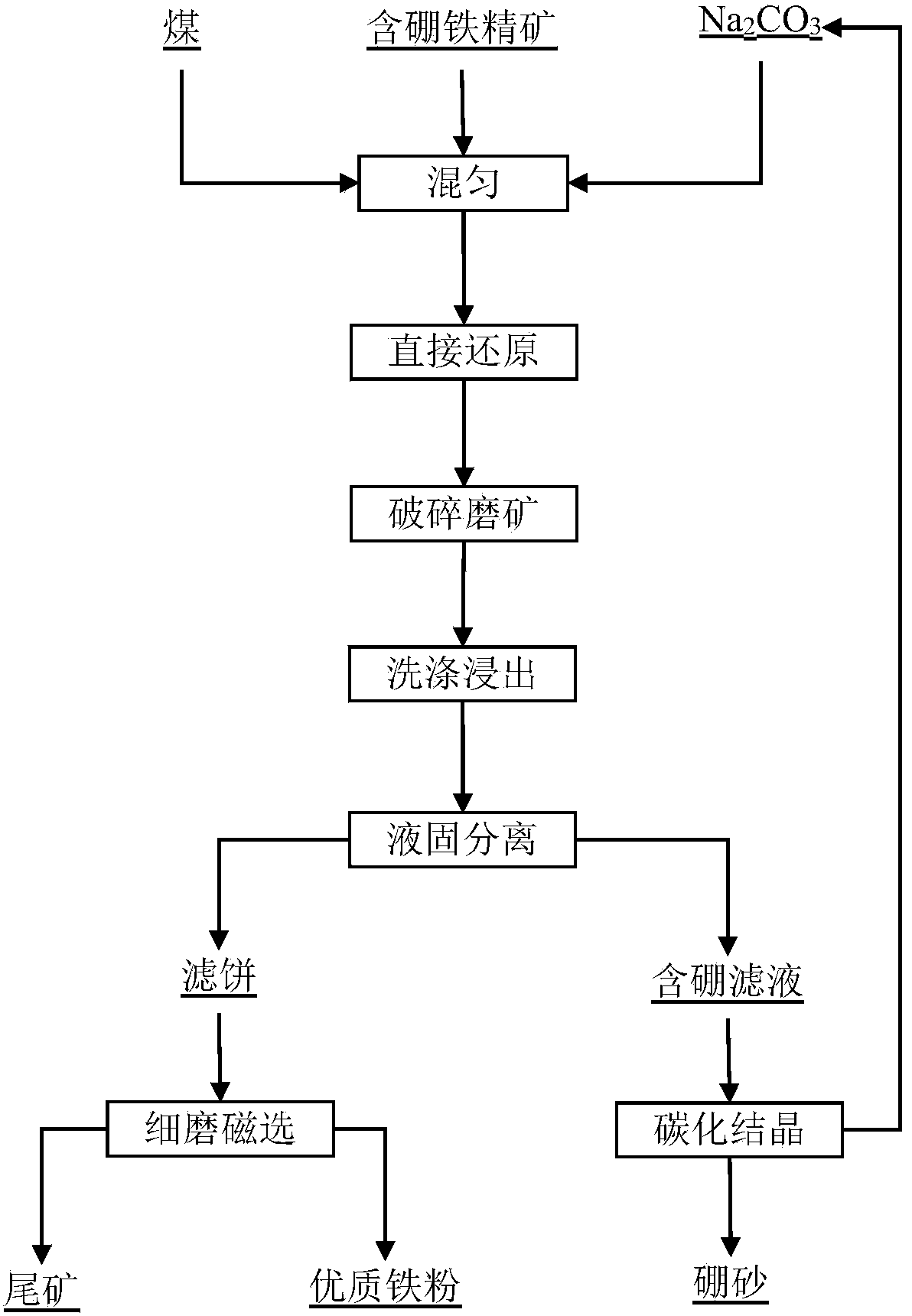

Image

Examples

Embodiment 1

[0038] Iron concentrate with 30wt% Na 2 CO 3It is mixed with 10wt% coal, and the mixed material and external coal blending are placed in a crucible in a tubular charging manner, kept at a temperature of 1100°C for 3 hours and then cooled, and the roasted product is crushed and ground (the particle size of the broken product is ≤ 10mm, the grinding fineness is -74μm and the content accounts for more than 40%) for leaching and washing, the leaching and washing temperature is 95°C, the leaching and washing time is 30min, the ratio of washing liquid to solid is 1:1, and the leaching rates of boron and sodium have reached more than 90 percent. The leaching slag is finely ground and magnetically separated to obtain a magnetically separated product (the fineness is -74μm, the content accounts for more than 80%, and the magnetic field strength is 60-100kA / m), and then dried in an inert atmosphere to obtain TFe>98.5% high-quality iron powder , The recovery rate of iron reaches more t...

Embodiment 2

[0040] Iron concentrate with 40%wt Na 2 CO 3 Mixed with 10%wt coal, the mixed material and external coal blending are placed in a crucible in a tubular charging manner, kept at a temperature of 1150°C for 4h and then cooled, and the roasted product is crushed and ground (the particle size of the crushed product is ≤10mm, the grinding fineness is -74μm and the content accounts for more than 40%) for leaching and washing, the leaching and washing temperature is 95°C, the leaching and washing time is 10min, the ratio of washing liquid to solid is 2:1, and the boron leaching rate reaches 90% above. The leaching slag is finely ground and magnetically separated to obtain a magnetically separated product (the fineness is -74μm, the content accounts for more than 80%, and the magnetic field strength is 60-100kA / m), and then dried in an inert atmosphere, the obtained TFe>98.5% high-quality iron The recovery rate of powder and iron reaches over 85%. Add lime milk to the alkaline filt...

Embodiment 3

[0042] Iron concentrate with 20% Na 2 CO 3 Mixed with 5%wt coal, the mixed material and external coal blending are placed in a crucible in a tubular charging manner, kept at a temperature of 950°C for 24 hours and then cooled, and the roasted product is crushed and ground (the particle size of the broken product is ≤ 10mm, the grinding fineness is -74μm and the content accounts for more than 40%) for leaching and washing, the leaching and washing temperature is 95°C, the leaching and washing time is 90min, the ratio of washing liquid to solid is 1.5:1, and the leaching rate of boron has reached 90%. above. The leaching slag is finely ground and magnetically separated to obtain a magnetically separated product (the fineness is -74μm, the content accounts for more than 80%, and the magnetic field strength is 60-100kA / m), and then dried in an inert atmosphere to obtain TFe>98.5% high-quality iron powder , The recovery rate of iron reaches more than 85%. Add lime milk to the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com