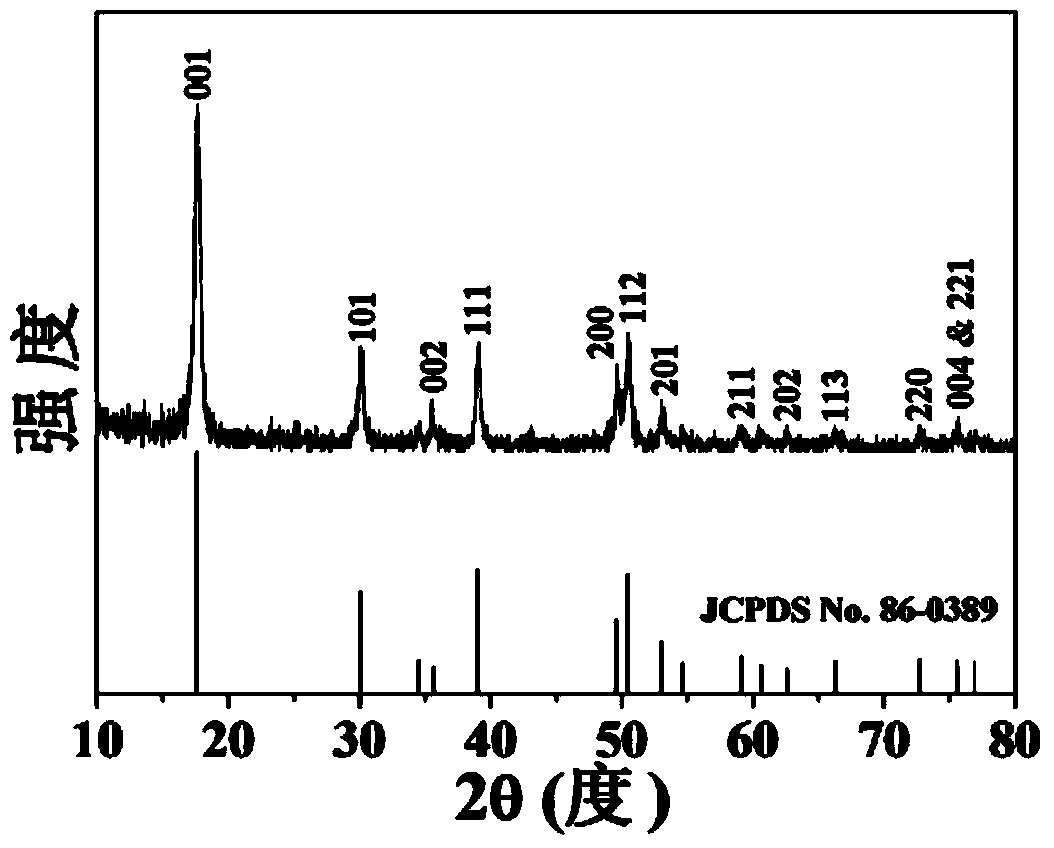

FeS nano-material and preparation method thereof

A kind of nano material and nano technology, applied in the direction of nano technology, nano technology, nano technology for materials and surface science, etc., can solve the problems of cumbersome methods, low production capacity, high cost, etc., and achieve simple process, high yield, and reaction The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A FeS nanometer material has a one-dimensional sheet structure, the thickness of the sheet-like FeS is 30-100 nanometers, and the diameter is 0.2-5 microns.

[0032] A preparation method of FeS nanomaterials, comprising the following steps:

[0033] (1) Potassium ferrocyanide and sodium sulfide are dissolved in water to form a uniform solution;

[0034] (2) Put the above homogeneous solution into a polytetrafluoroethylene-lined autoclave, react under hydrothermal conditions at 200°C for 10 hours, and then cool naturally to room temperature;

[0035] (3) The product was cleaned by centrifugation with deionized water and ethanol, and vacuum-dried at 60° C. for 6 hours to constant weight to obtain a sheet-shaped FeS electrode material.

[0036] The concentration of potassium ferrocyanide in the step (1) is 0.05mol / L, the concentration of sodium sulfide is 0.05mol / L; the filling degree of the reactor in the step (2) is 80%.

Embodiment 2

[0040] A FeS nanometer material has a one-dimensional sheet structure, the thickness of the sheet-like FeS is 20-60 nanometers, and the diameter is 0.2-4.0 microns.

[0041] A preparation method of FeS nanomaterials, comprising the following steps:

[0042] (1) Dissolve ammonium ferrocyanide and sodium sulfide in water, add a certain amount of polyvinylpyrrolidone, and magnetically stir to form a uniform solution;

[0043] (2) Put the above homogeneous solution into a polytetrafluoroethylene-lined autoclave, react under hydrothermal conditions at 220°C for 3 hours, and then cool naturally to room temperature;

[0044] (3) The product was cleaned by centrifugation with deionized water and ethanol, and vacuum-dried at 40° C. for 8 hours to constant weight to obtain a sheet-shaped FeS electrode material.

[0045] In described step (1), the concentration of potassium ferrocyanide is 0.1mol / L, and the concentration of sodium sulfide is 0.1mol / L, and the concentration of polyvinylp...

Embodiment 3

[0047] A FeS nanometer material has a one-dimensional sheet structure, the thickness of the sheet-like FeS is 20-80 nanometers, and the diameter is 0.3-4.5 microns.

[0048] A preparation method for FeS nanomaterials, the steps comprising:

[0049] (1) Dissolve ferrous sulfate and sodium sulfide in water, add a certain amount of polyvinyl alcohol, and magnetically stir to form a uniform solution;

[0050] (2) Put the above homogeneous solution into a polytetrafluoroethylene-lined autoclave, react under hydrothermal conditions at 140°C for 10 hours, and then cool naturally to room temperature;

[0051] (3) The product was cleaned by centrifugation with deionized water and ethanol, and vacuum-dried at 30° C. for 10 hours to constant weight to obtain a sheet-shaped FeS electrode material.

[0052] In described step (1), the concentration of ferrous sulfate is 1.0mol / L, and the concentration of sodium sulfide is 1.0mol / L, and the concentration of polyvinyl alcohol is 4.0mol / L; In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com