Device and method for eradicating secondary oxidation of tundish during continuous casting

A secondary oxidation and tundish technology, which is applied to casting equipment, casting molten material containers, manufacturing tools, etc., can solve the problem of difficulty in maintaining a non-oxidizing atmosphere in tundishes, scrapping or downgrading of sub-casting billets, and serious secondary oxidation of molten steel and other problems, to achieve the effect of improving the quality of the first billet, reducing the defects of the casting billet, and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0034] The present invention aims at various deficiencies in the existing tundish sealing method and provides a device and method for preventing secondary oxidation of the tundish in the continuous casting process. The device is composed of a tundish sealing cover 1 and a gas shut-off system.

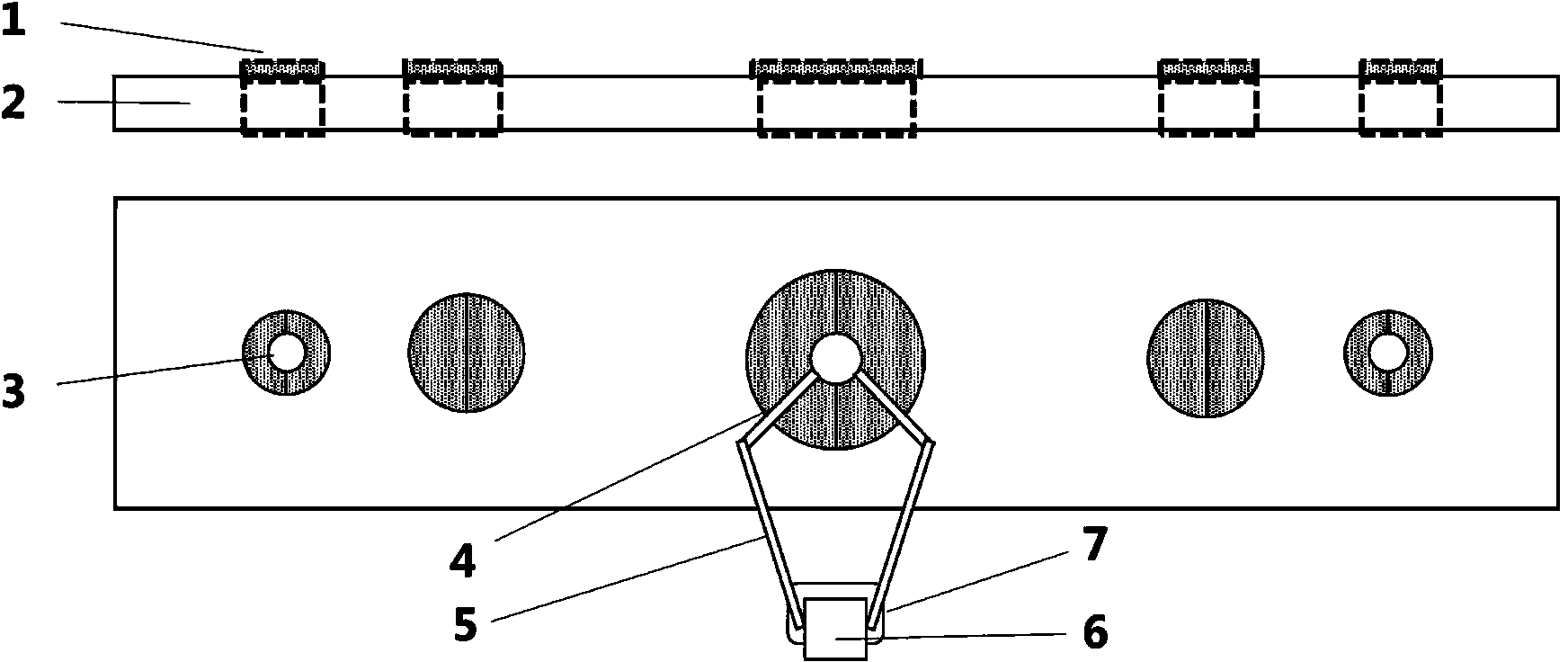

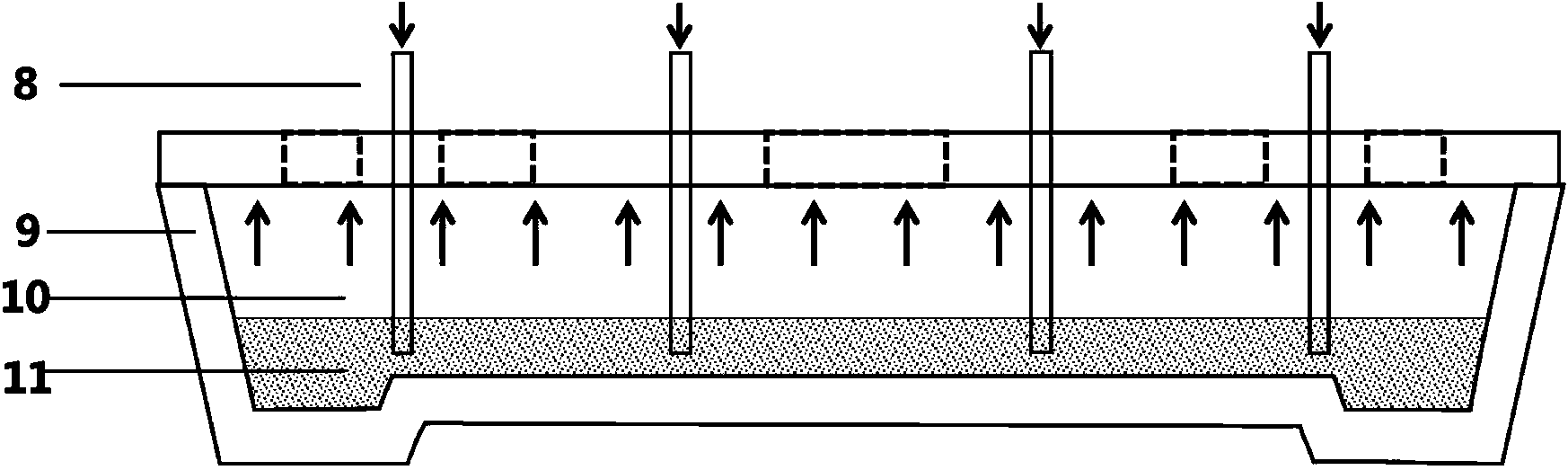

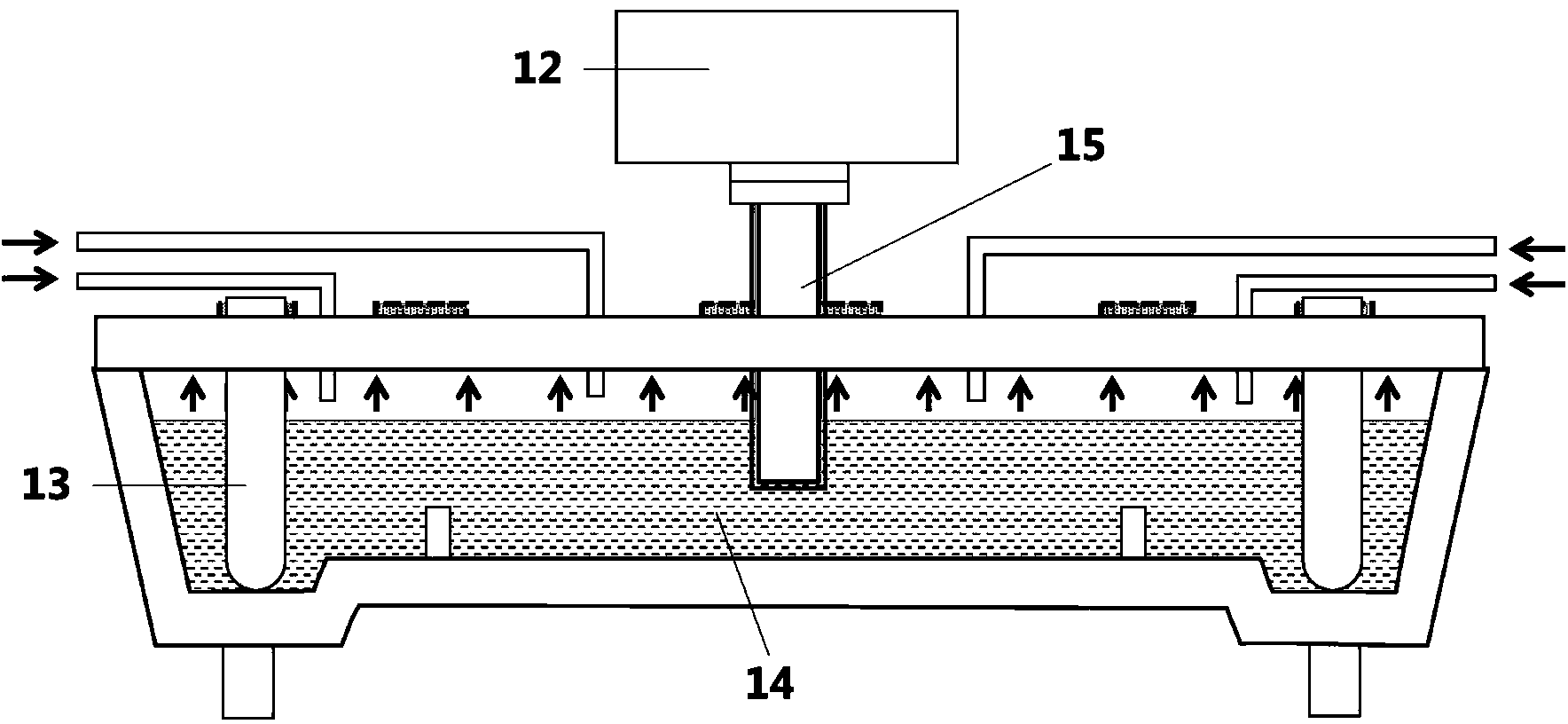

[0035] Such as figure 1 As shown, it is a structural schematic diagram of a tundish sealing cover of a device for preventing secondary oxidation of the tundish in the continuous casting process of the present invention, wherein the tundish sealing cover 1 includes a tundish cover 2, a split heat-insulating sealing cover 3, and a forearm 4 , rocker arm 5, moving seat 6 and base 7, there are reserved holes for installing stopper rod 13 and long nozzle 15 on the spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com