A kind of cobalt-free lithium-rich manganese-based positive electrode material and its preparation method and application

A cobalt-rich lithium-manganese-based, positive electrode material technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low cycle times, small battery specific capacity, poor performance, etc., and achieve complete crystal structure, The effect of many cycles and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

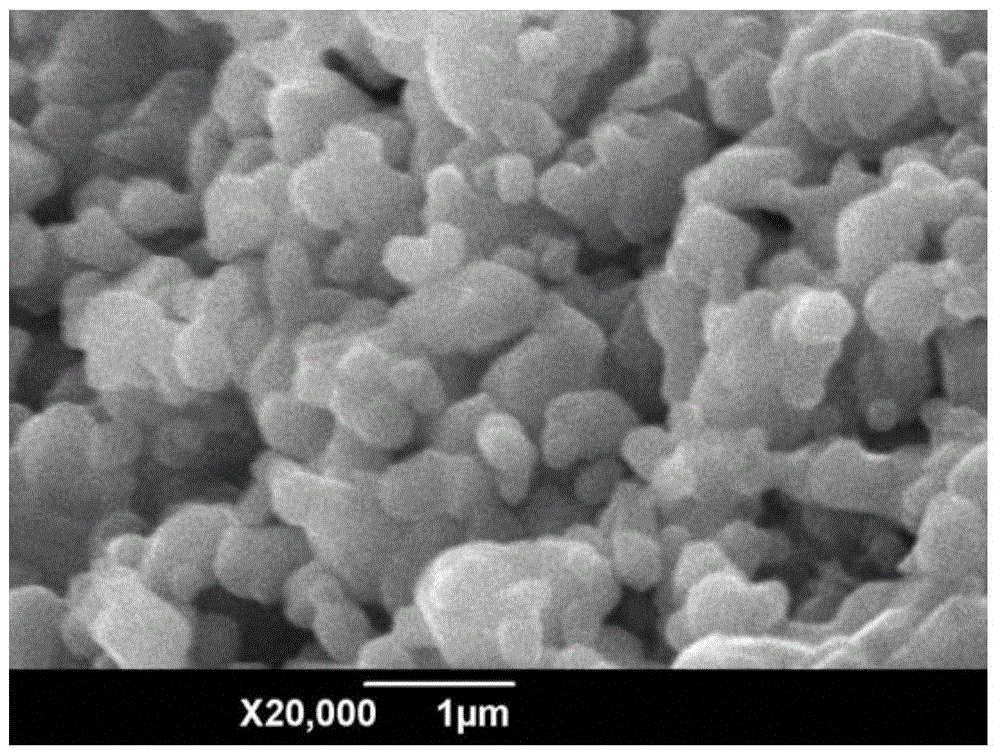

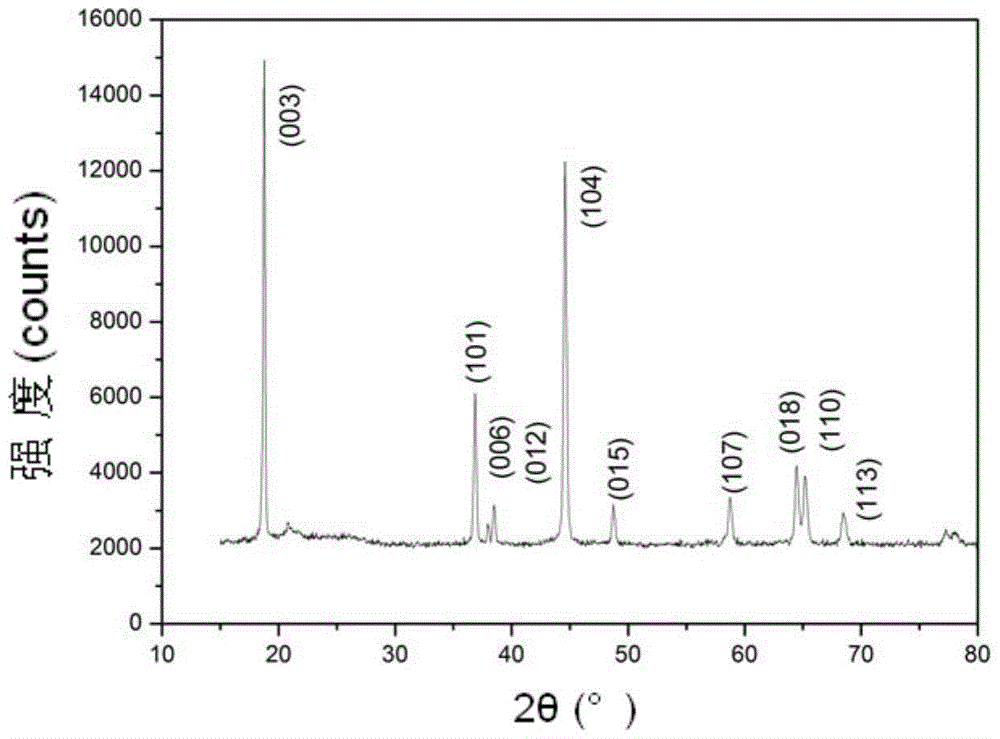

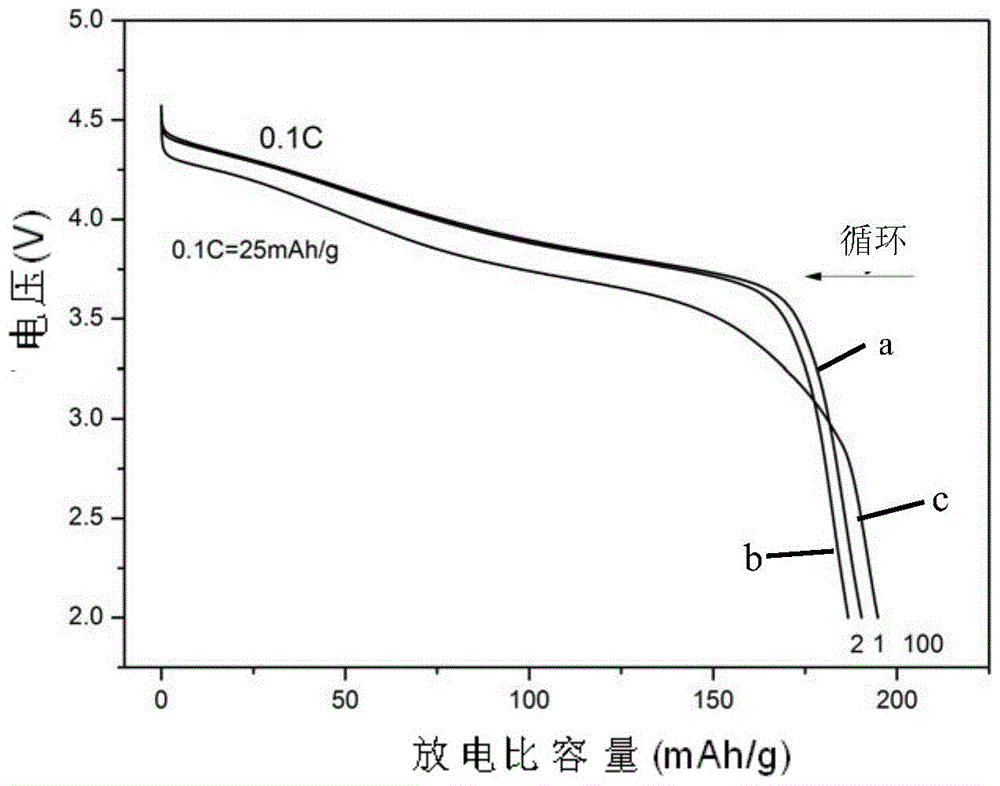

[0030]1) Dissolve 0.6mol of lithium acetate, 0.2mol of nickel nitrate and 0.2mol of manganese acetate in absolute ethanol, stir well and add polyethylene glycol with a molecular weight of 400 (ie, PEG 400 ), the resulting solution was stirred at 80°C at a stirring speed of 600r / min for 12h to obtain a green gel;

[0031] 2) The green gel is pretreated at low temperature in the furnace to obtain a brown-black loose substance, and then the brown-black loose substance is ball-milled for 2 hours to make it uniform, and then high-temperature treatment is carried out in the furnace; finally, the obtained The material is ground and sieved to obtain a cobalt-free lithium-rich manganese-based positive electrode material;

[0032] Among them, the low-temperature pretreatment process is as follows: the green gel is heated to 400°C at a heating rate of 3°C / min in an air atmosphere, kept for 60 minutes, and then cooled to room temperature with the furnace;

[0033] The high-temperature tr...

Embodiment 2

[0042] 1) Dissolve 0.6 mol of lithium acetate, 0.1 mol of nickel acetate and 0.3 mol of manganese acetate in deionized water, stir well and add polyethylene glycol with molecular weight of 1000 (ie PEG 1000 ), the resulting solution was stirred at 80°C at a stirring speed of 700r / min for 12h to obtain a green gel;

[0043] 2) The green gel is pretreated at low temperature in the furnace to obtain a brown-black loose substance, and then the brown-black loose substance is ball-milled for 5 hours to make it uniform, and then high-temperature treatment is carried out in the furnace; finally, the obtained material after high-temperature treatment Grinding and sieving to obtain a cobalt-free lithium-rich manganese-based positive electrode material;

[0044] Among them, the low-temperature pretreatment process is as follows: the green gel is heated to 500°C at a heating rate of 5°C / min in an air atmosphere, kept for 30 minutes, and then cooled to room temperature with the furnace;

...

Embodiment 3

[0053] 1) Dissolve 0.6 mol of lithium nitrate, 0.2 mol of nickel nitrate and 0.2 mol of manganese nitrate in absolute ethanol, stir well and add polyethylene glycol with a molecular weight of 10000 (i.e. PEG 10000 ), the resulting solution was stirred at 80°C for 12 hours at a stirring speed of 800r / min to obtain a green gel;

[0054] 2) The green gel is pretreated at low temperature in the furnace to obtain a brown-black loose substance, and then the brown-black loose substance is ball-milled for 5 hours to make it uniform, and then high-temperature treatment is carried out in the furnace; finally, the obtained material after high-temperature treatment Grinding and sieving to obtain a cobalt-free lithium-rich manganese-based positive electrode material;

[0055] Among them, the low-temperature pretreatment process is as follows: the green gel is heated to 400°C at a heating rate of 5°C / min in an air atmosphere, kept for 60 minutes, and then cooled to room temperature with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com