Thin-wall part complex working condition machining state monitoring method

A technology of processing state and complex working conditions, which is applied in the direction of instruments, computer control, simulators, etc., can solve the problems of complex thin-walled parts, single processing state monitoring items, and inability to reflect the coupling effect of various processing states, so as to ensure the quality of processing Quality, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following structural drawings and embodiments further illustrate the present invention.

[0041] like Figure 1-13 shown.

[0042] In this embodiment, aluminum alloy is used as the cutting test material, and a cemented carbide end mill is used as the cutting tool. The Kistler amplifier is used to collect mechanical signals, and the acceleration sensor is used to collect vibration signals.

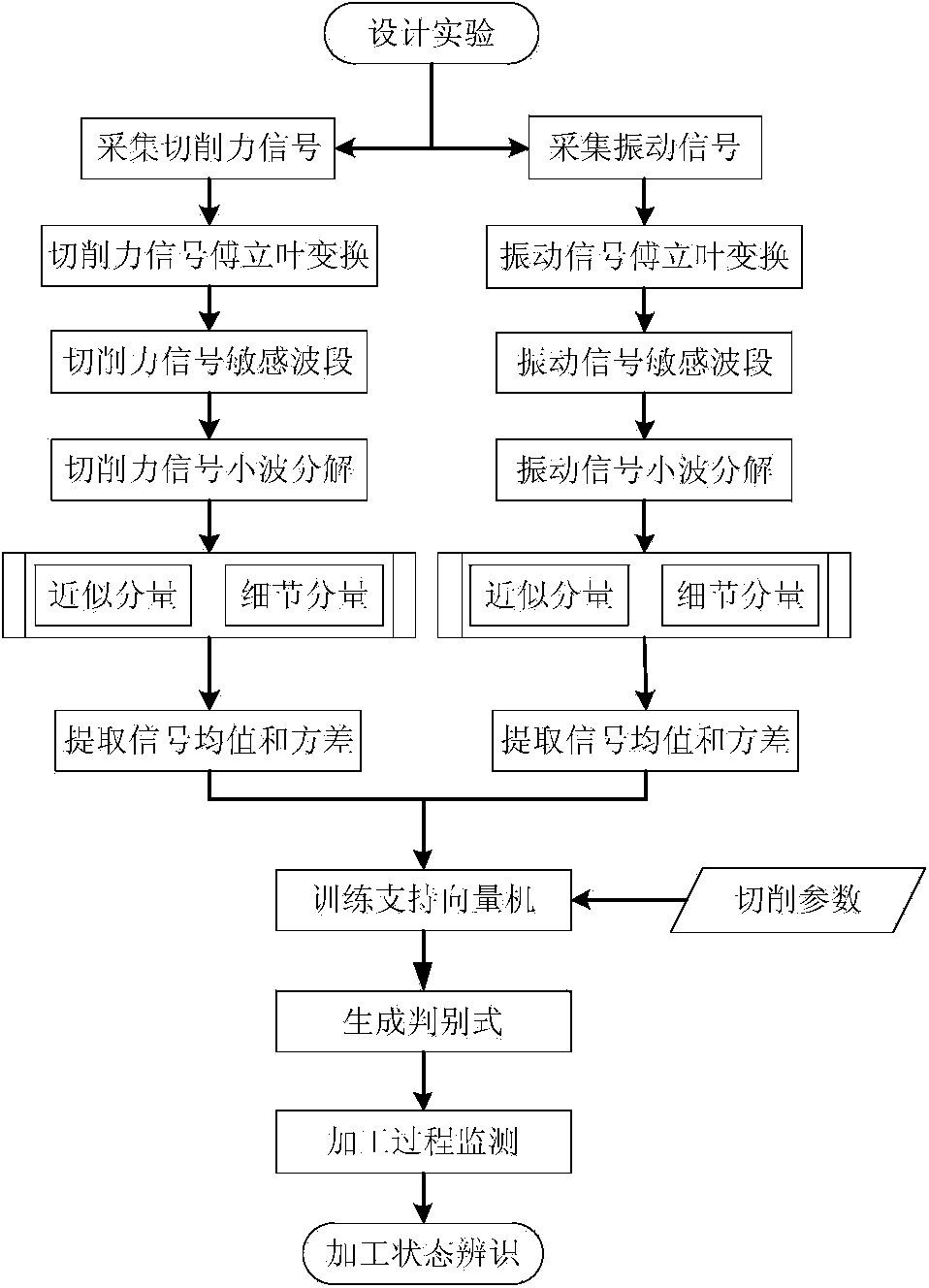

[0043] figure 1 It is a flow chart of the complex working condition processing state monitoring method based on multi-sensor fusion and support vector machine of the present invention. like figure 1 As shown, a method for monitoring the processing status of thin-walled parts under complex working conditions, which includes the following steps:

[0044] 1. Test environment

[0045] The test conditions of this embodiment include a five-axis numerical control machine tool, a three-way dynamometer, and an acceleration sensor; two cutting tools are used: a non-wearing tool; and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com