A nanometer superparamagnetic mine hoist brake shoe formula and manufacturing method thereof

A mine hoist, superparamagnetic technology, applied to chemical instruments and methods, mechanical equipment, other chemical processes, etc., can solve the problems of magnetic field control without material conditions and technical foundation, and achieve improved braking performance and reliability , good heat resistance, the effect of reducing wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

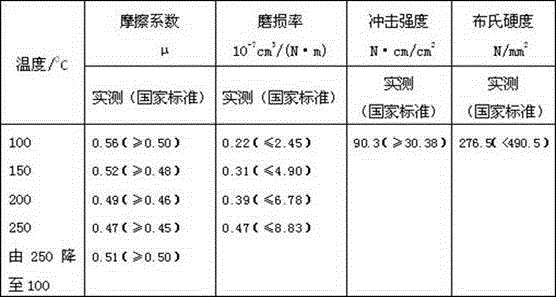

[0035] Cashew shell oil modified phenolic resin 12 parts; nitrile rubber 4 parts; glass fiber 18 parts; acicular wollastonite 15 parts; aramid fiber 5 parts, graphite 4 parts, feldspar powder 8 parts, zeolite 6 parts, friction powder 4 parts, 10 parts of barium sulfate, carbon-coated nano-Fe 3 o 4 (below 16nm) 10 parts, silane coupling agent 2 parts, release agent 2 parts.

Embodiment 2

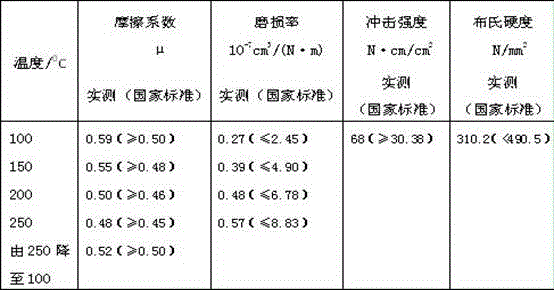

[0037] Cashew shell oil modified phenolic resin 10 parts; nitrile rubber 3 parts; glass fiber 15 parts; acicular wollastonite 18 parts; aramid fiber 4 parts, graphite 2 parts, feldspar powder 15 parts, zeolite 8 parts, friction powder 5 parts, 11 parts of barium sulfate, 5 parts of carbon-coated α-Fe (below 5nm), 2 parts of silane coupling agent, and 2 parts of release agent.

Embodiment 3

[0039] Cashew shell oil modified phenolic resin 15 parts; nitrile rubber 5 parts; glass fiber 15 parts; acicular wollastonite 12 parts; aramid fiber 8 parts, graphite 2 parts, feldspar powder 8 parts, zeolite 5 parts, friction powder 4 parts, 10 parts of barium sulfate, carbon-coated α-Fe 2 o 3 (Below 20nm) 15 parts, 3 parts of silane coupling agent, 2 parts of release agent.

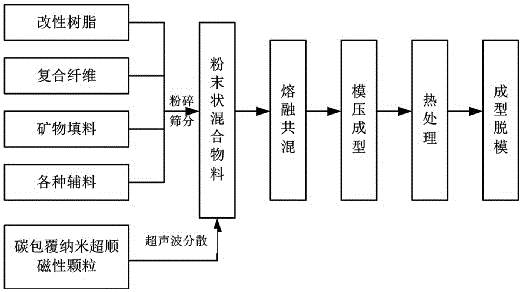

[0040] Such as figure 1 Shown: The manufacturing method of nano superparamagnetic mine hoist brake shoes, all raw materials are dried in a drying box at a temperature of 30°C for 6 hours; the fiber materials are made into short fibers; the block materials are passed through a pulverizer processing, crushing into fine crushing; put the material into the mixer for high-speed mixing for 20-30min; disperse the carbon-coated nano-superparamagnetic particles by ultrasonic wave for 30-50min; The paramagnetic particles are added to the powdery material and mixed with a mixer for 20-30 minutes, and melted and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com