A new type of composite wear-resistant material, its preparation method and its application

A wear-resistant material and a new type of technology, applied in chemical instruments and methods, mechanical equipment, and other chemical processes, can solve problems such as uneven distribution of brake pad material components and structures, difficulty in fully flowing adhesives, and long drying time , to achieve the effect of excellent macro comprehensive performance, improved service life and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

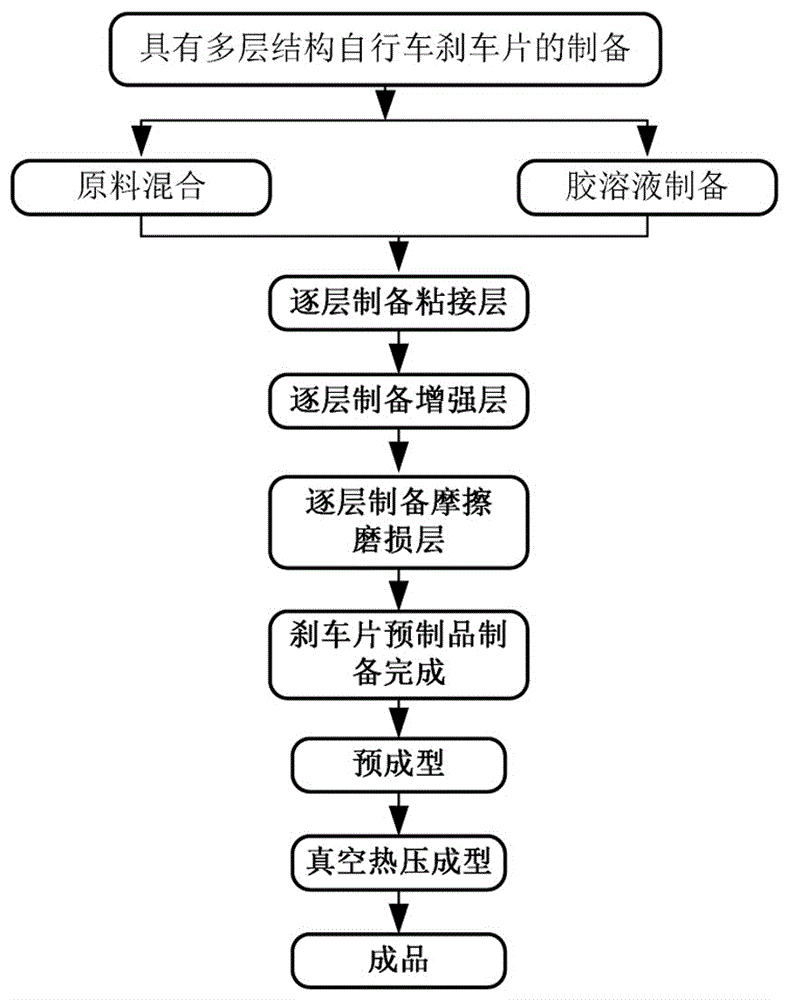

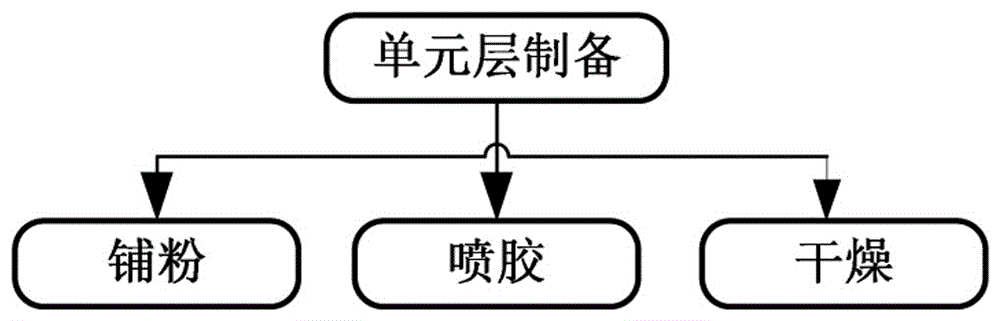

Method used

Image

Examples

Embodiment 1

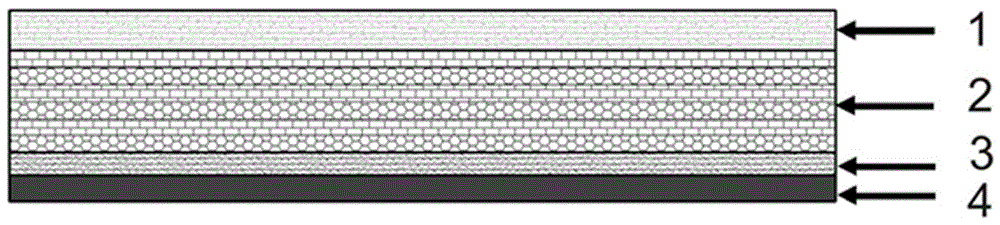

[0046] A composite wear-resistant material, its material composition and mass parts are:

[0047] The material composition and mass fraction of the adhesive layer unit layer are:

[0048] Mixed powder: 22.5 parts of NBR powder, 7.5 parts of tire powder, 0.75 part of accelerator DM powder, 1 part of zinc oxide powder, 0.75 part of N-phenyl-β-naphthylamine powder, and 1.5 parts of sulfur powder.

[0049] Liquid reagents: 12.5 parts of liquid phenolic resin, 1.5 parts of silane coupling agent KH-550, 1.5 parts of dibutyl phthalate (DBP), 0.5 parts of melamine, and 50 parts of absolute ethanol.

[0050] The material composition and mass fraction of the reinforcement layer unit layer are:

[0051] Mixed powder: 10 parts of nitrile rubber powder, 10 parts of barium sulfate powder, 5 parts of calcium carbonate powder, 0.5 part of accelerator DM powder, 0.5 part of zinc oxide powder, 0.5 part of N-phenyl-β-naphthylamine powder, sulfur 1 serving of powder.

[0052] Liquid reagents: 9 ...

Embodiment 2

[0079] A composite wear-resistant material, the material composition and mass parts are:

[0080] The material composition and mass fraction of the friction and wear layer unit layer are:

[0081] Mixed powder: 10 parts of nitrile rubber powder, 2.5 parts of silicon dioxide powder, 2.5 parts of alumina powder, 7 parts of artificial graphite powder, 3 parts of antimony sulfide powder, 4 parts of barium sulfate powder, 4 parts of calcium carbonate powder, coal ash 1 part of powder, 1 part of coke powder, 0.25 part of accelerator DM powder, 0.5 part of zinc oxide powder, 0.25 part of N-phenyl-β-naphthylamine powder, and 1 part of sulfur powder.

[0082] Liquid reagent: 10 parts of liquid phenolic resin, 2 parts of silane coupling agent KH-5502, 0.5 part of dibutyl phthalate (DBP), 0.5 part of melamine, and 50 parts of absolute ethanol.

[0083] The material composition and mass fraction of the reinforcement layer unit layer are:

[0084] Mixed powder: 10 parts of nitrile rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com