Brake block and its manufacturing method

A brake block and brake technology, applied in the field of manufacturing such brake blocks, disc or drum brakes, can solve the problems of difficult production process, difficult quality control, complex production process, etc., and achieve light weight, easy The effect of simple production and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

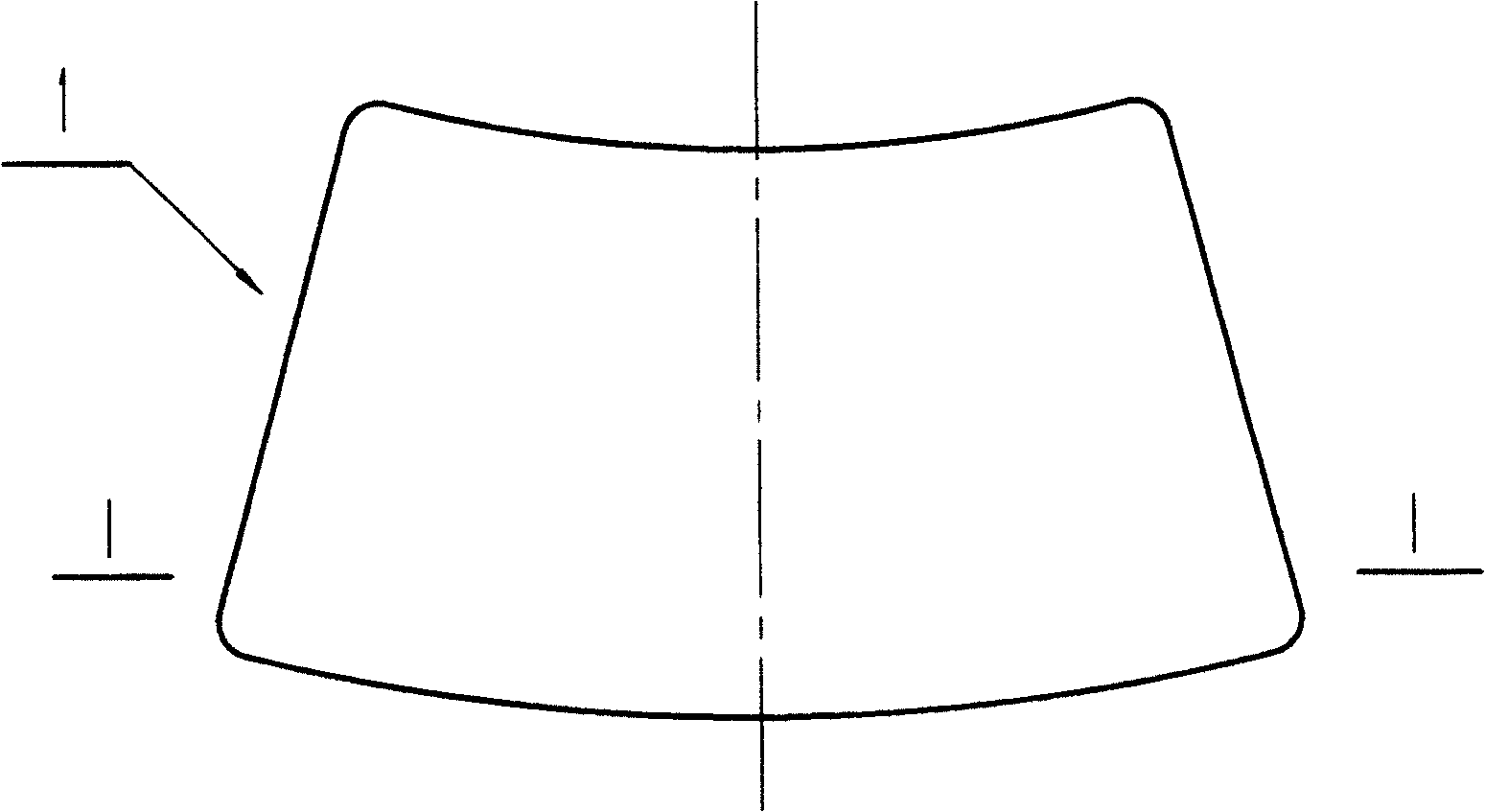

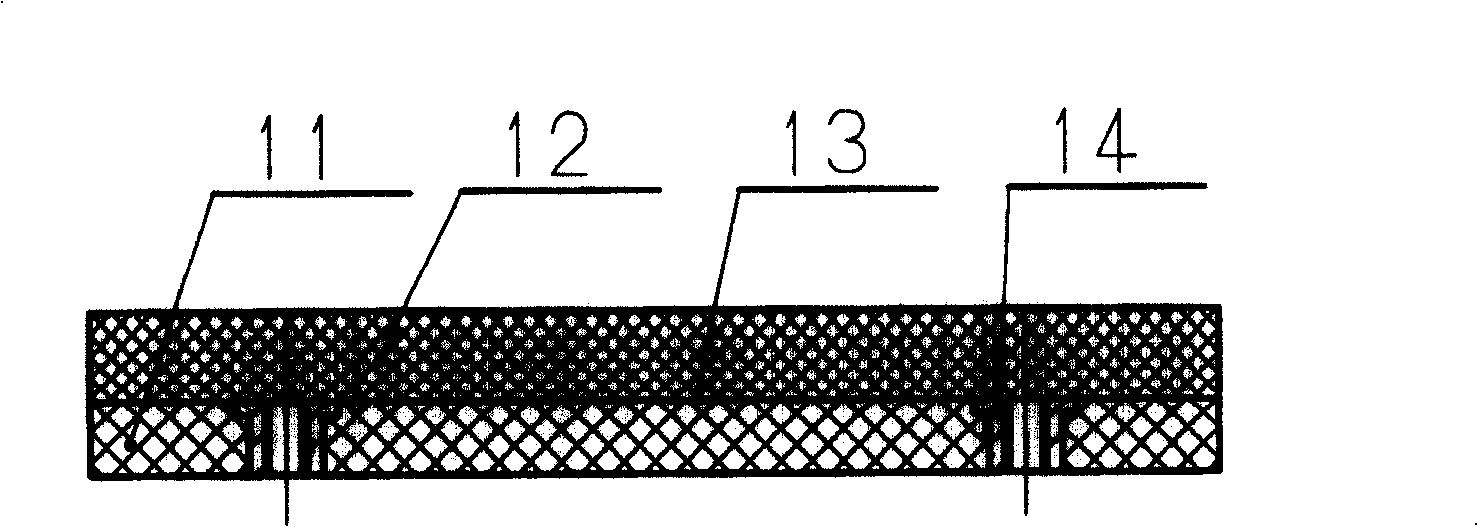

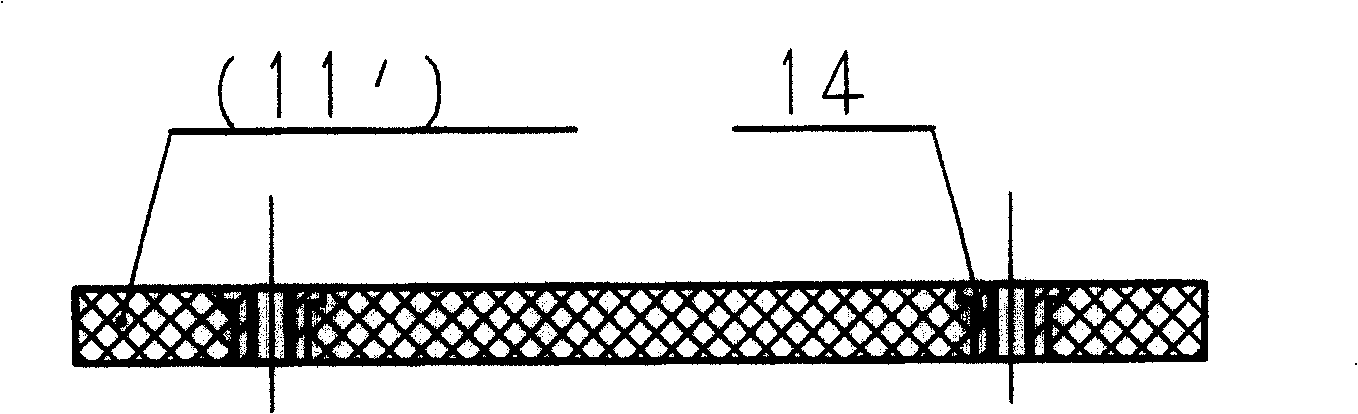

[0015] Such as Figures 1 to 5 As shown, a disc or drum brake pad 1, especially for disc or drum brake pads 1 for oil drilling rigs, mine hoists, heavy construction machinery, and heavy trucks, includes a base plate 11 and a base plate 11 The friction plate 12 that is bonded together by heat and pressure. The bottom plate 11 is made of fiberglass material, and the friction plate 12 is made of friction material.

[0016] Preferably, the glass fiber reinforced plastic material with nitrile-modified phenolic formaldehyde as the binder is used as the thermosetting material for manufacturing the bottom plate 11, and a polymer resin with a network structure is formed through condensation polymerization reaction, and mixed with glass fiber materials, fillers, lubricants, etc. Make the brake shoe bottom plate 11. Among them, 35-40% of resin, 45-50% of glass fiber (100-250mm in length) material, 10-15% of calcium carbonate, magnesium oxide, coloring agent, etc., and 1-1.2% of lubrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com