Novel micropore corundum brick and preparation method thereof

A corundum brick and microporous technology, which is applied in the field of new microporous corundum brick and the preparation of the microporous corundum brick, can solve the problems of reduced refractory performance, poor microporation effect, damage to the original structure, etc., and achieves an increase in volume. Density and microporation, uniform temperature distribution in the kiln, and the effect of improving the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

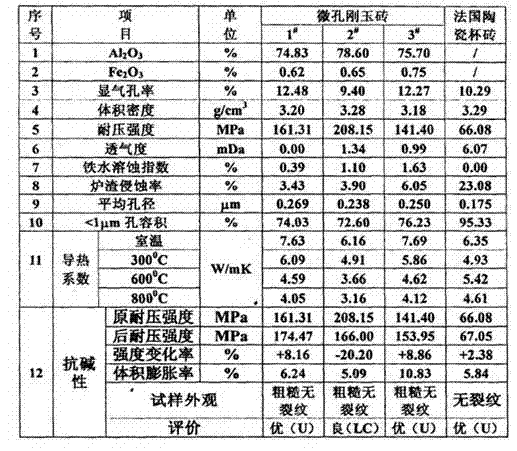

Image

Examples

Embodiment 1

[0022] A new type of microporous corundum brick, characterized in that: the novel microporous corundum brick is prepared from the following raw materials in weight ratio, wherein, metal silicon 7%, silicon carbide 8%, aluminum oxide 7% , dense corundum 44%, mullite 8%, brown corundum 32%, resin 4%.

[0023] The present embodiment realizes by following proportioning and processing step:

[0024] a. Raw material crushing: crush dense corundum into 32% of the total weight ratio of particle size 0.1~3.2mm, and 12% of particle size smaller than 320 mesh; crush brown corundum into small particles with particle size of 1~3.2mm, and crush mullite into small particles with particle size smaller than 320 mesh fine powder, metal silicon is crushed into a fine powder with a particle size of less than 320 mesh, silicon carbide is crushed into a fine powder with a particle size of less than 200 mesh, and aluminum oxide is crushed into a fine powder with a particle size of less than 600 ...

Embodiment 2

[0031] A new microporous corundum brick, characterized in that: the novel microporous corundum brick is prepared from the following raw materials in weight ratio, wherein, metal silicon 8%, silicon carbide 5%, aluminum oxide 4% , dense corundum 40%, mullite 9%, brown corundum 30%, resin 3%.

[0032] The present embodiment realizes by following proportioning and processing step:

[0033]a. Raw material crushing: crush dense corundum into 27% of the total weight ratio of particle size 0.1~3.2mm, and 13% of particle size smaller than 320 mesh; crush brown corundum into small particles with particle size of 1~3.2mm, and crush mullite into particles smaller than 320 mesh fine powder, metal silicon is crushed into a fine powder with a particle size of less than 320 mesh, silicon carbide is crushed into a fine powder with a particle size of less than 200 mesh, and aluminum oxide is crushed into a fine powder with a particle size of less than 600 mesh;

[0034] b. Aggregate mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com