A flocculant for purifying landscape water and its preparation method

A flocculant and landscape technology, applied in the field of new flocculants, can solve the problems of difficult large-scale production, poor water quality adaptability, large quantities, etc., and achieve the effect of high efficiency of turbidity and algae removal, not harsh water conditions, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The mass percent of each raw material in the PSFZn in this example is: industrial water glass 30%, ferric chloride 1%, zinc sulfate 2%, dilute hydrochloric acid is 10%, sodium bicarbonate 10%, surplus is deionized water.

[0030] Concrete preparation method is as follows:

[0031] (1) After diluting the water glass with deionized water, slowly add it to part (half) of dilute hydrochloric acid under magnetic stirring at a speed of 500r / min, and adjust the pH value to 4 with the remaining (half) hydrochloric acid, at 20 The polysilicic acid solution was obtained after activation at ℃ for 30 minutes.

[0032] (2) Put FeCl at a speed of 300r / min 3 , ZnSO 4 Added to the polysilicic acid solution mentioned above one after another, after stirring for 25min. Sodium bicarbonate was added, and stirring was continued for 10 min to obtain PSFZn.

Embodiment 2

[0038] In the PSFZn in this example, each raw material is by mass percentage: industrial water glass 25%, ferric chloride 4%, zinc sulfate 4%, dilute hydrochloric acid is 20%, sodium bicarbonate 10%, surplus is deionized water.

[0039] Concrete preparation method is as follows:

[0040] (1) After diluting the water glass with deionized water, slowly add it to some dilute hydrochloric acid under magnetic stirring at a speed of 400r / min, adjust the pH value to 5 with the remaining hydrochloric acid, and activate at 40°C for 20 minutes After that, polysilicic acid solution is obtained.

[0041] (2) Put FeCl at a speed of 300r / min 3 , ZnSO 4 Added to the polysilicic acid solution mentioned above one after another, after stirring for 45min. Sodium bicarbonate was added, and stirring was continued for 15 min to obtain PSFZn.

Embodiment 3

[0047] The raw materials in PSFZn in this example are by mass percentage: industrial water glass 21%, ferric chloride 8%, zinc sulfate 4%, dilute hydrochloric acid is 20%, sodium bicarbonate 5%, surplus is deionized water.

[0048] Concrete preparation method is as follows:

[0049] (1) After diluting the water glass with deionized water, slowly add it to part (such as 2 / 3) of dilute hydrochloric acid under magnetic stirring at a speed of 600r / min, and then use the remaining (such as 1 / 3) The pH value was adjusted to 6 with hydrochloric acid, and the polysilicic acid solution was obtained after activation at 28° C. for 30 minutes.

[0050] (2) Put FeCl at a speed of 400r / min 3 , ZnSO 4 Add it to the polysilicic acid solution mentioned above, and stir for 60 minutes. Sodium bicarbonate was added, and stirring was continued for 20 min to obtain PSFZn.

PUM

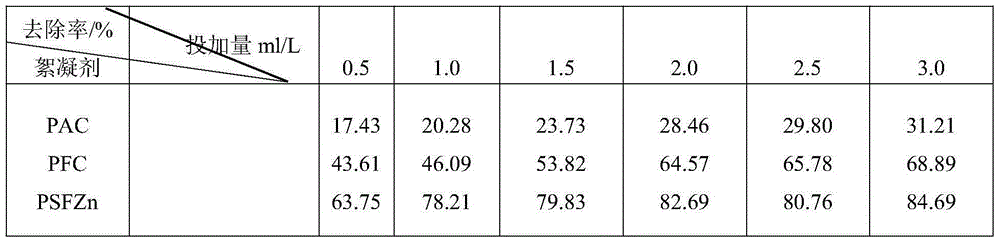

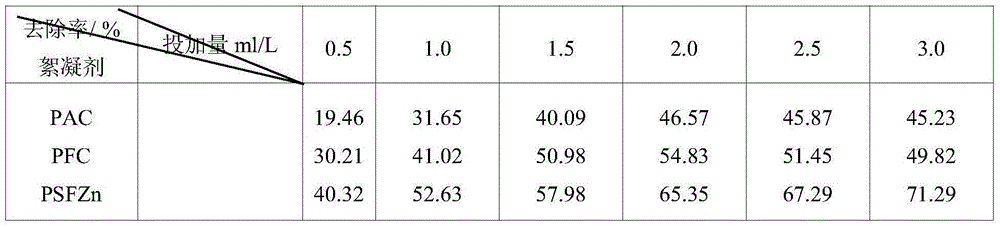

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com