A kind of integrated circuit flip welding hermetic packaging structure

A technology of integrated circuit and packaging structure, which is applied in the field of integrated circuit reverse welding airtight sealing structure, which can solve the problems of destroying the airtightness of chip packaging and cracking of the covering metal layer, and achieves the protection of airtightness, sealing size and sealing The effect of highly miniaturized and air-tightness guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the accompanying drawings.

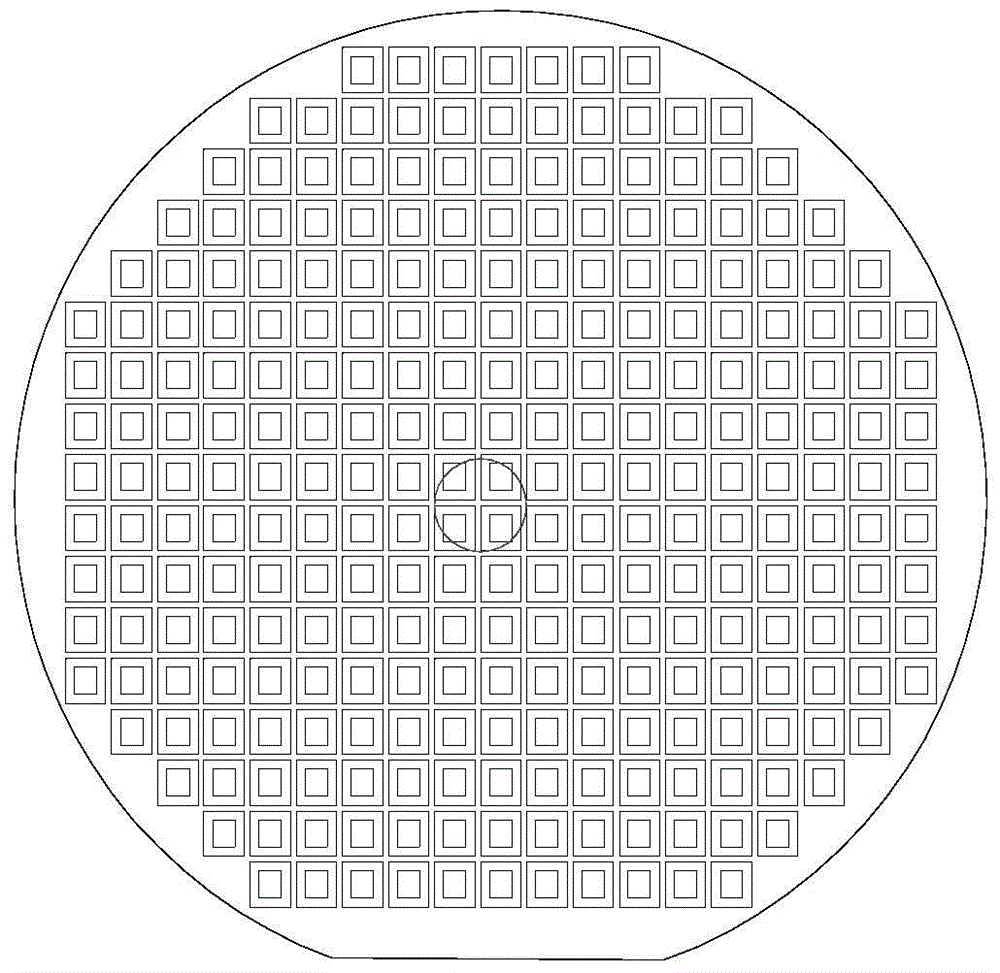

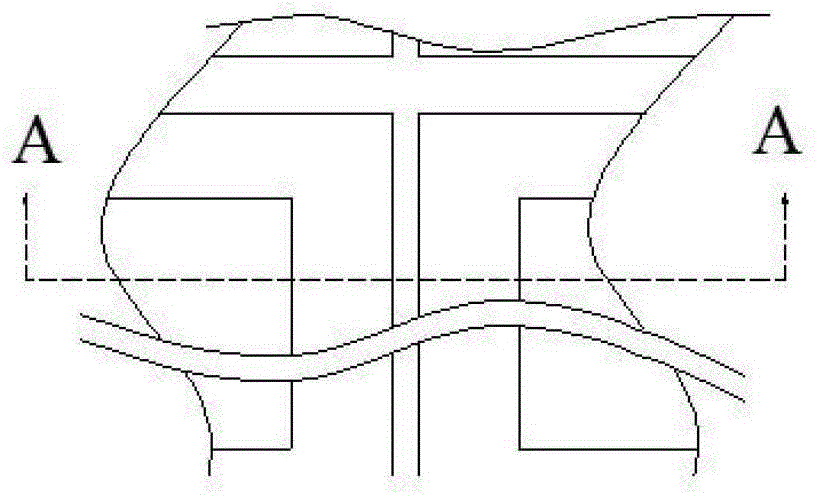

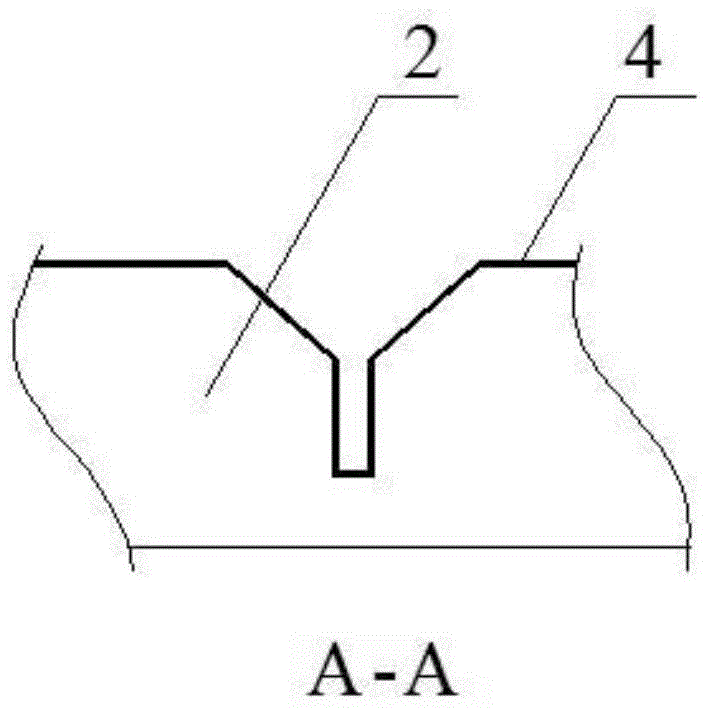

[0016] Such as Figure 5 Shown is a cross-sectional view of the overall integrated circuit upside-down soldering hermetic package structure of the present invention, the structure includes a ceramic substrate 1, a flip-chip 2, a filling resin 3, a metallization layer 4 on the back of the chip, and chip bumps (solder balls) 5. It is composed of annular solder 6 and solder 7, a Kovar sealing cover plate 8, a ceramic metallized sealing ring 9, and an outer terminal pad 10. Wherein, the metallization layer 4 on the backside of the chip generally includes an adhesion layer, a barrier layer, and a soldering layer structure.

[0017] The chip 2 is formed by thinning the back of the wafer, grooving, chamfering, evaporating or sputtering a multi-layer metallization layer under vacuum, and then cutting with a diamond wheel; the formed metallization layer 4 includes adhesive Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com