An additive manufacturing auxiliary printing lifting platform

An additive manufacturing and lifting platform technology, applied in the field of additive manufacturing, can solve the problems of long time consumption, increased labor cost, air tightness effect, etc., and achieve the effect of improving printing effect, shortening time, and air tightness protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

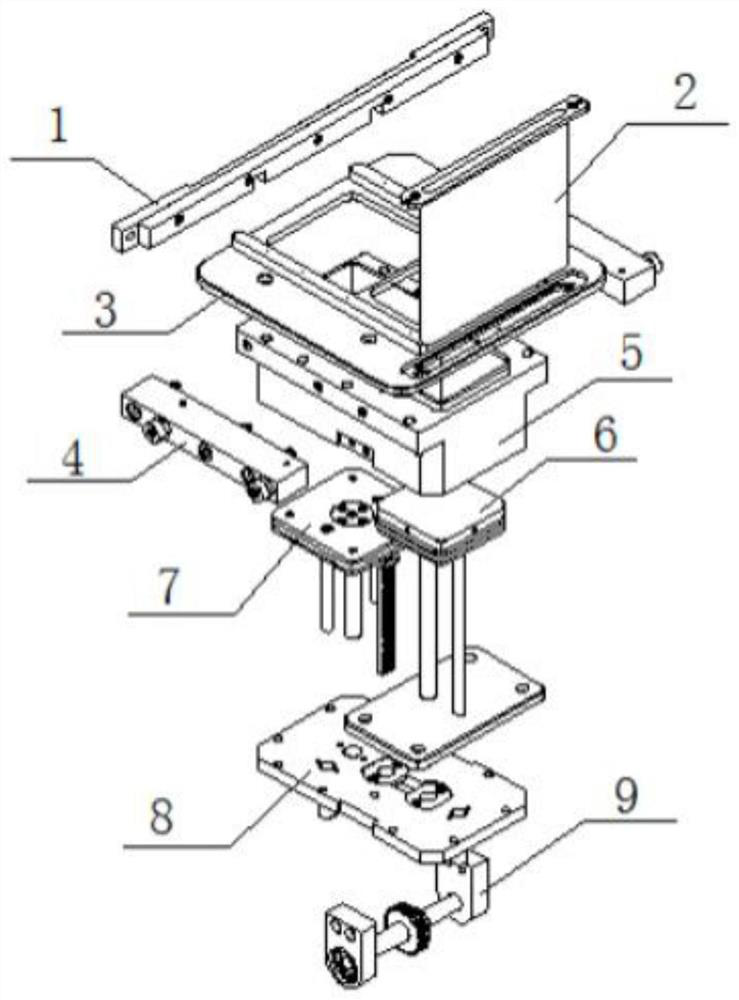

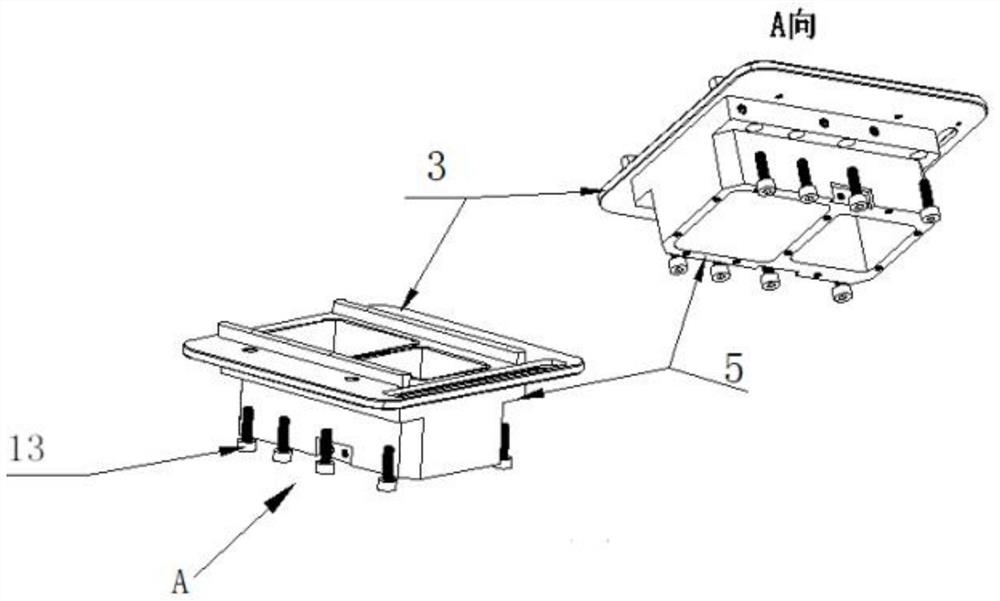

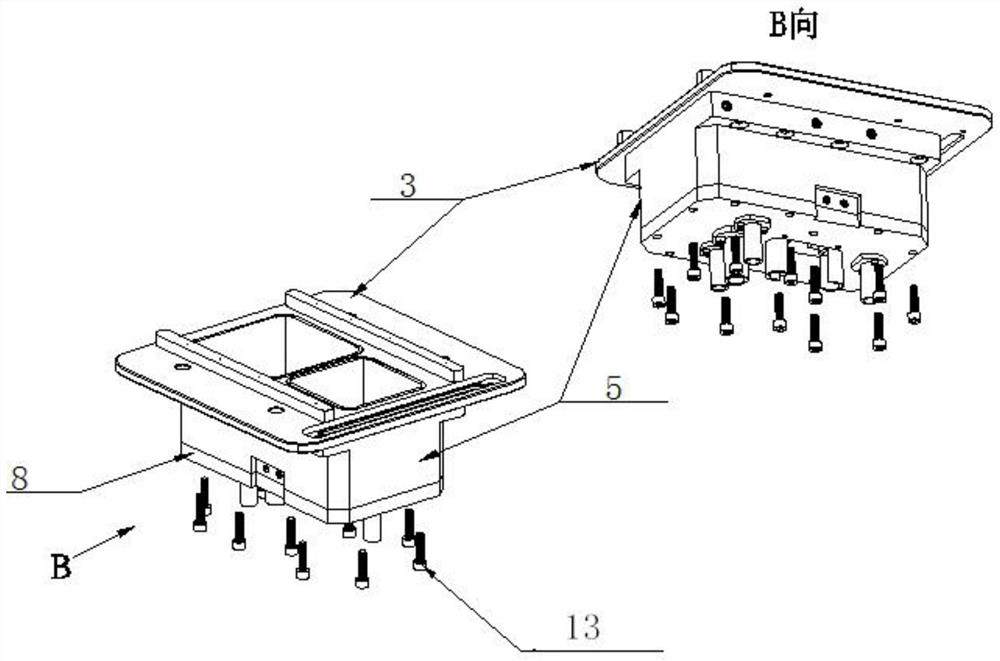

[0042] as attached Figure 1-11 The illustrated lifting platform for additive manufacturing auxiliary printing includes a forming platform 6 whose bottom is fixed on the working platform 30 of the original metal fusion deposition printing equipment. The working platform 30 is provided with threaded holes 11, and the forming platform 6 is fixed by fixing screws. 13 fits the threaded hole 11 and is fixedly connected with the working platform 30; the top of the forming platform 6 passes through the empty chamber 5, and the middle part is connected with the transmission device 9 fixed on the bottom of the empty chamber 5, and the transmission device 9 is located on the forming platform 6 The other side is connected with the powder storage platform 7; the forming platform 6 and the powder storage platform 7 can move up and down with respect to the empty bin 5 under the action of the transmission device 9, specifically, the molding platform 6 moves down layer by layer, and the powder...

Embodiment 2

[0058] On the basis of the first embodiment, the present invention also provides a metal fused deposition printing device, including the additive manufacturing-assisted printing lifting platform as described in the first embodiment, and the use process is similar to that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com