Toilet paper additive, toilet paper making method using toilet paper additive and toilet paper

A manufacturing method and technology of toilet paper, applied in the field of toilet paper, can solve the problems of reduced fiber strength of raw material pulp, insufficient effect, increased utilization rate of waste paper from hardwood pulp, etc., and achieve excellent dry paper strength, stable manufacturing, and expanded selection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

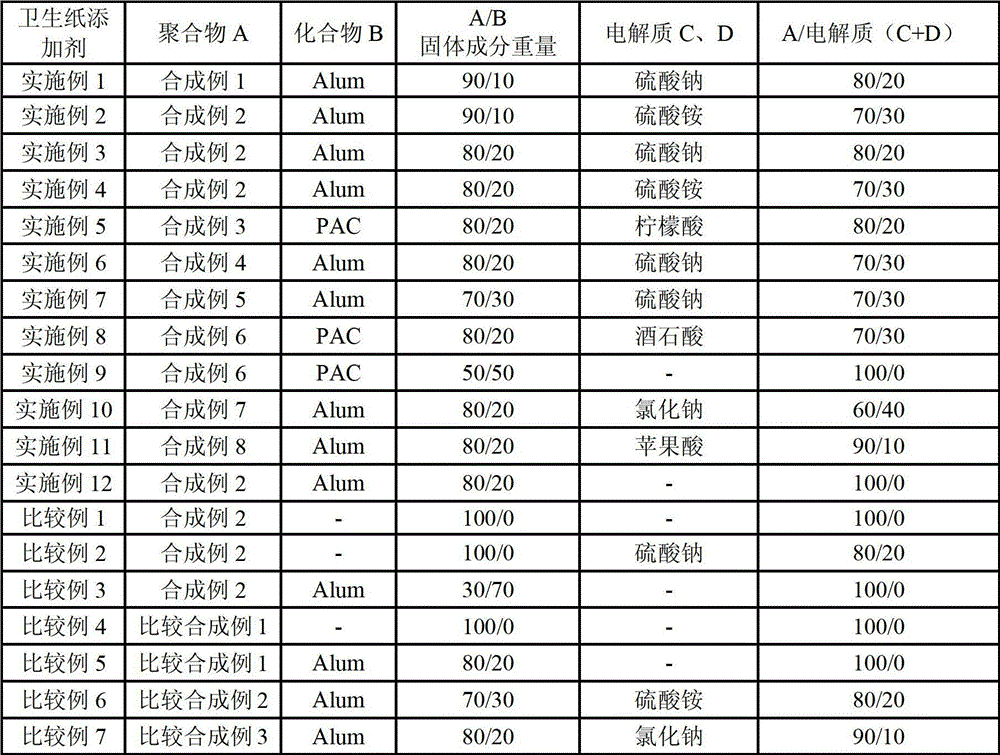

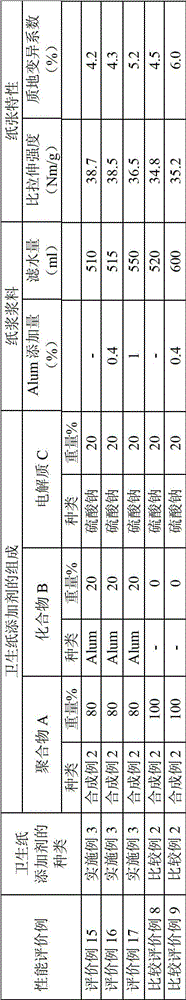

Examples

Embodiment

[0032] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated more concretely, this invention is not limited to these examples. In addition, in each example, unless otherwise specified, "part" and "%" are based on weight.

[0033] Each measurement was performed by the following method.

[0034] (1) Weight of solid components

[0035] After drying in a dryer at 105° C. for 3 hours, the solid content weights of polymer A and various pulp slurries were measured.

[0036] (2) Viscosity

[0037] Measured at 25°C using a B-type viscometer.

[0038] (3) Weight average molecular weight

[0039] Measured under the following measurement conditions:

[0040] GPC host: manufactured by Tosoh Corporation

[0041] Chromatographic column: 1 guard column PWXL and 2 GMPWXL columns manufactured by Tosoh Corporation (temperature 40°C)

[0042] Eluent: N / 2 acetic acid buffer solution (N / 2 acetic acid (manufactured by Wako Junpharma Co., Ltd.)...

Synthetic example 1

[0047] In the reaction device with stirrer, thermometer, reflux condenser, nitrogen gas introduction pipe and 2 dropping funnels, add 376 parts of ion-exchanged water, pass nitrogen gas to remove oxygen in the reaction system, and then heat to 90°C. Add 208 parts of acrylamide, 9.1 parts of 80% acrylic acid, 1.6 parts of sodium methallyl sulfonate, 0.3 parts of dimethyl acrylamide, 0.5 parts of methylenebisacrylamide, and dimethacrylic acid into a dropping funnel. 26.5 parts of methylaminoethyl ester, 79.8 parts of benzyl chloride quaternary ammonium salt solution of 60% dimethylaminoethyl methacrylate and 534 parts of ion-exchanged water were used to adjust the pH to 3 with 62.5% sulfuric acid. Furthermore, 0.45 parts of ammonium persulfate and 180 parts of ion-exchanged water were added to another dropping funnel. Next, the monomer and the catalyst were added dropwise into the system through two dropping funnels for about 3 hours. After dropping, add 0.3 parts of ammonium p...

Synthetic example 2~8

[0048] Synthesis Examples 2-8, Comparative Synthesis Examples 1-3

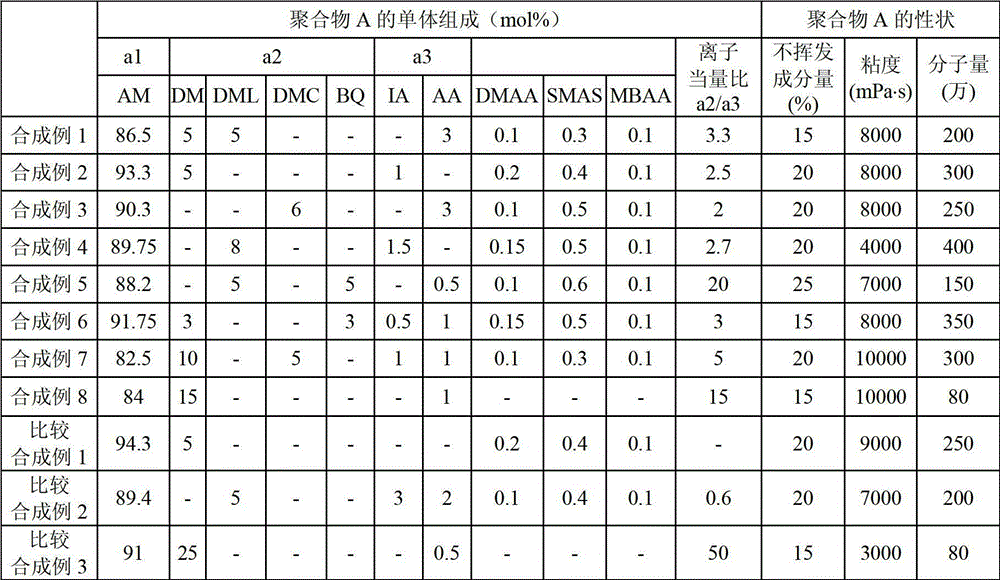

[0049] Polymer A was synthesized in the same manner as in Synthesis Example 1, except that the monomer composition in Synthesis Example 1 was changed to that shown in Table 1. The properties of the obtained polymer A are shown in Table 1.

[0050] Table 1

[0051]

[0052] The names of the short names in Table 1 are as follows:

[0053] AM: acrylamide

[0054] DM: Dimethylaminoethyl methacrylate

[0055] DML: Benzyl chloride quaternary ammonium salt of dimethylaminoethyl methacrylate

[0056] DMC: Methyl chloride quaternary ammonium salt of dimethylaminoethyl methacrylate

[0057] BQ: benzyl chloride quaternary ammonium salt of dimethylaminoethyl acrylate

[0058] IA: itaconic acid (diacid)

[0059] AA: Acrylic

[0060] DMAA: Dimethacrylamide

[0061] SMAS: Sodium Methallyl Sulfonate

[0062] MBAA: Methylenebisacrylamide

[0063] Ion equivalent ratio a2 / a3: cation equivalent of polymer A / anion eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com