High-efficiency sound-insulating material and manufacturing method thereof

A sound-insulating material and high-efficiency technology, which is applied in the direction of chemical instruments and methods, instruments, sound-generating devices, etc., can solve problems that endanger human health, produce toxic gases, and have insignificant effects of sound-insulating materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

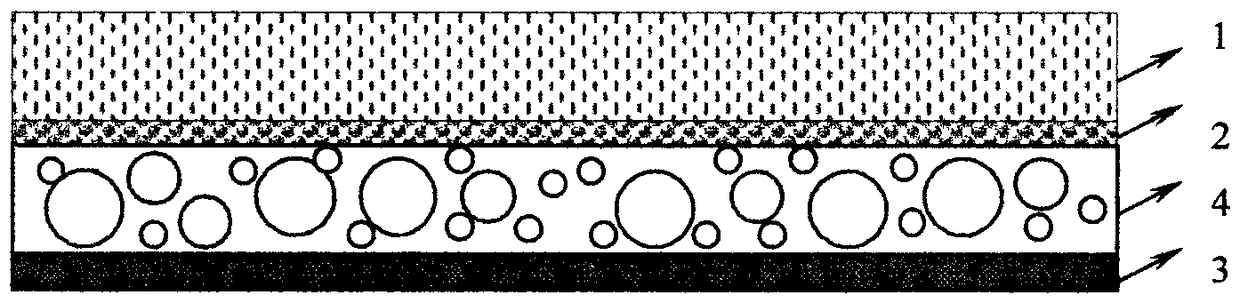

[0067] correspond figure 1 / sound insulation material shown in table 1

[0068] Raw materials: m-LLDPE thermoplastic resin 40kg; azodicarbonamide ratio 10kg; zinc oxide 2.5kg; petroleum resin 5kg; 2,6-di-tert-butyl-p-cresol 2.5kg; micron calcium carbonate fine powder 40kg; Zinc acid 2kg, DINP 3.5kg; 2,6-di-tert-butyl-p-cresol 1kg; petroleum resin C91kg; triphenyl phosphate 1kg; zinc stearate 1kg;

[0069] Foamed PET sheet, foamed PET sheet as sound-absorbing layer;

[0070] Preparation and pretreatment of nano-submicron-micron inorganic fine powder

[0071] Using a ball mill, with the same parameter configuration, such as at a constant speed of 50rpm, grind the micron-sized inorganic filler for 10 days respectively to obtain ball sample 1, sheet sample 1, and needle sample 1; after 1.5 days, obtain ball sample 2, sheet sample 2, Needle sample 2; 5 hours, get ball sample 3, sheet sample 3, needle sample 3. Then, the materials that have been ground for different times are m...

Embodiment 2

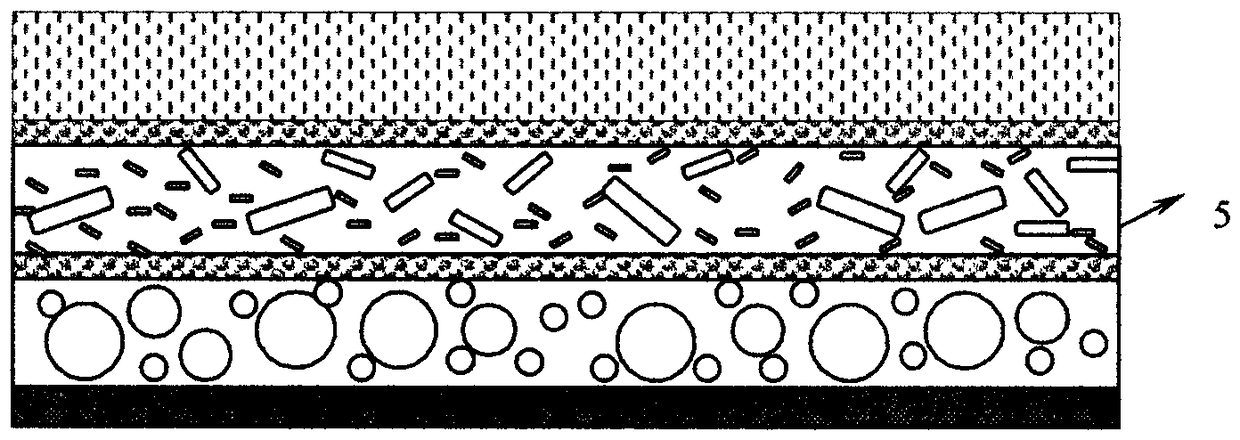

[0081] correspond figure 2 / Raw materials of sound insulation materials shown in Table 2: m-LLDPE thermoplastic resin 40kg; azodicarbonamide ratio 10kg; zinc oxide 2.5kg; petroleum resin 5kg; 2,6-di-tert-butyl-p-cresol 2.5kg; Calcium fine powder (40kg); micron flaky kaolin (40kg); zinc stearate 2kg; DINP 3.5kg; 2,6-di-tert-butyl-p-cresol 1kg; petroleum resin C9 1.5kg; triphenyl phosphate 1kg ;

[0082] Foamed PET sheet; Then, calcium carbonate and kaolin were ground into fine powders in the same manner as in Example 1, characterized, and mixed. And the same manner as in Example 1 was used to prepare the sound-insulating composition of granular and needle-shaped fillers. The final sound-insulating layer consists of two layers, which are respectively made of sound-insulating composites containing sheet-like and granular inorganic fillers; the carpet, sound-insulating layer and sound-absorbing layer are overlapped in this way to prepare a multi-layer sound-insulating material...

Embodiment 3

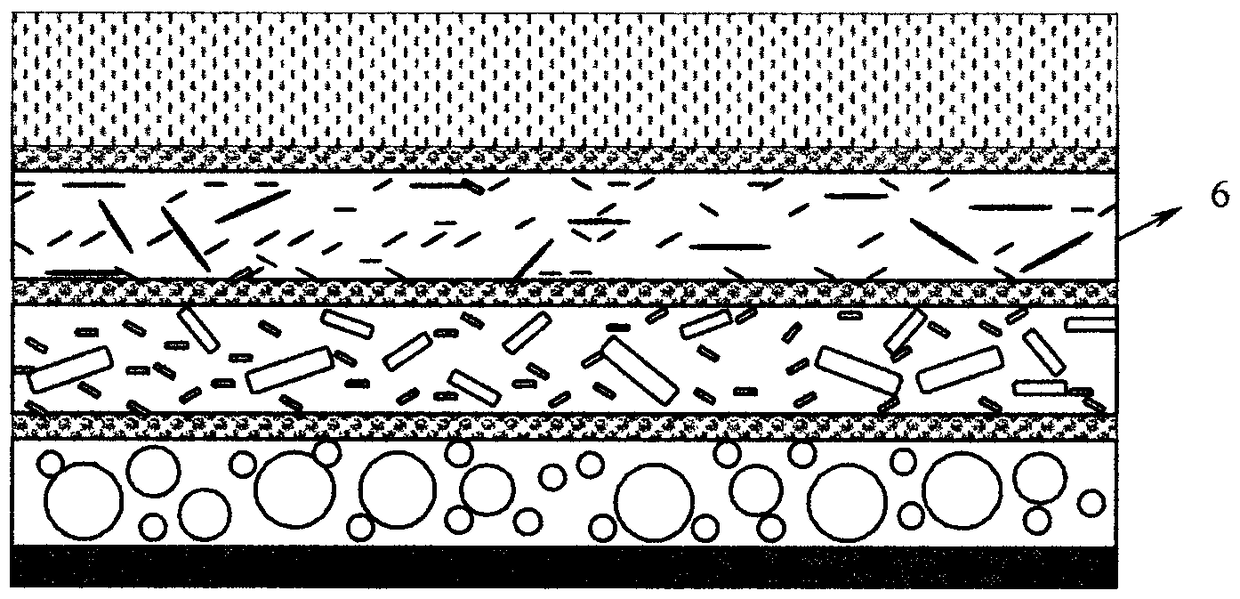

[0087] correspond image 3 / sound insulation material shown in table 3

[0088] Raw materials: m-LLDPE thermoplastic resin 40kg; azodicarbonamide ratio 10kg; zinc oxide 2.5kg;

[0089] Petroleum resin 5kg; 2,6-di-tert-butyl-p-cresol 2.5kg micron grade calcium carbonate fine powder (40kg);

[0090] Micron flaky kaolin (40kg); micron wollastonite (40kg); zinc stearate 2kg; DINP 3.5kg; 2,6-di-tert-butyl-p-cresol 1kg; petroleum resin C9 1.5kg

[0091] Triphenyl phosphate 1kg;

[0092] Foamed PET sheet;

[0093] Then, calcium carbonate, kaolin and wollastonite were ground into fine powder by the same method as in Example 1, characterized and mixed. And the same method as in Example 1 was used to prepare the sound-insulating composition of granular, flake and needle-shaped fillers. The final sound-insulating layer consists of three layers, which are respectively prepared from sound-insulating composites containing sheet-like, granular and needle-shaped inorganic fillers; the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com