Inert atmosphere protecting chamber of laser solid forming equipment

A technology of laser three-dimensional forming and inert atmosphere, which is applied in the direction of improving process efficiency and energy efficiency, can solve the problems of large volume of protection room, increased processing cost, inconvenient operation, etc., to simplify the operation process, improve work efficiency, The effect of shortening the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

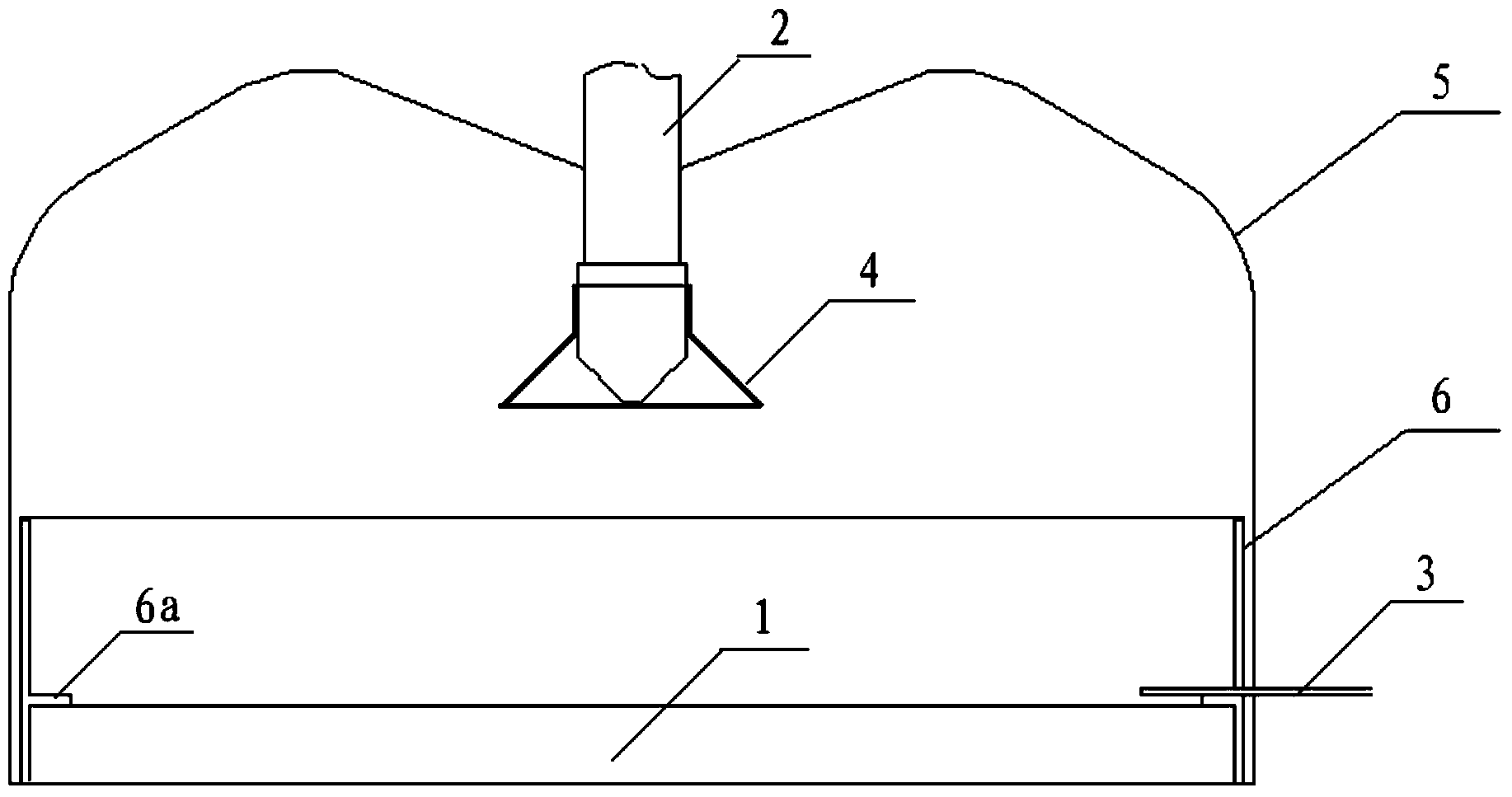

Image

Examples

Embodiment

[0011] Laser cladding CoCrMo hard alloy layer is carried out on the turbine blade of a certain type of engine. The material of the turbine blade is DZ125 alloy. 1.2mm. The positioning tool is placed in an inert atmosphere protection room, the blade is installed on the positioning tool, and the plastic bag 5 is bound on the laser nozzle by plastic tape. Pass the air intake pipe through the hole of the plastic bag and the hole of the light-shielding tube into the inside of the light-shielding tube. Turn on the argon gas source before processing the parts, set the argon pressure at 0.2Mpa, inflate the inert atmosphere protection chamber for at least 10 minutes, and then process the parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com