Method for preparing lithium ion battery porous silicon composite cathode material by industrial silicon waste material

A technology of lithium ion battery and negative electrode material, applied in the field of electrochemistry, can solve the problems of complex process, generation of pollutants, expensive raw materials, etc., and achieve the effects of simple treatment method, reduced pollution and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

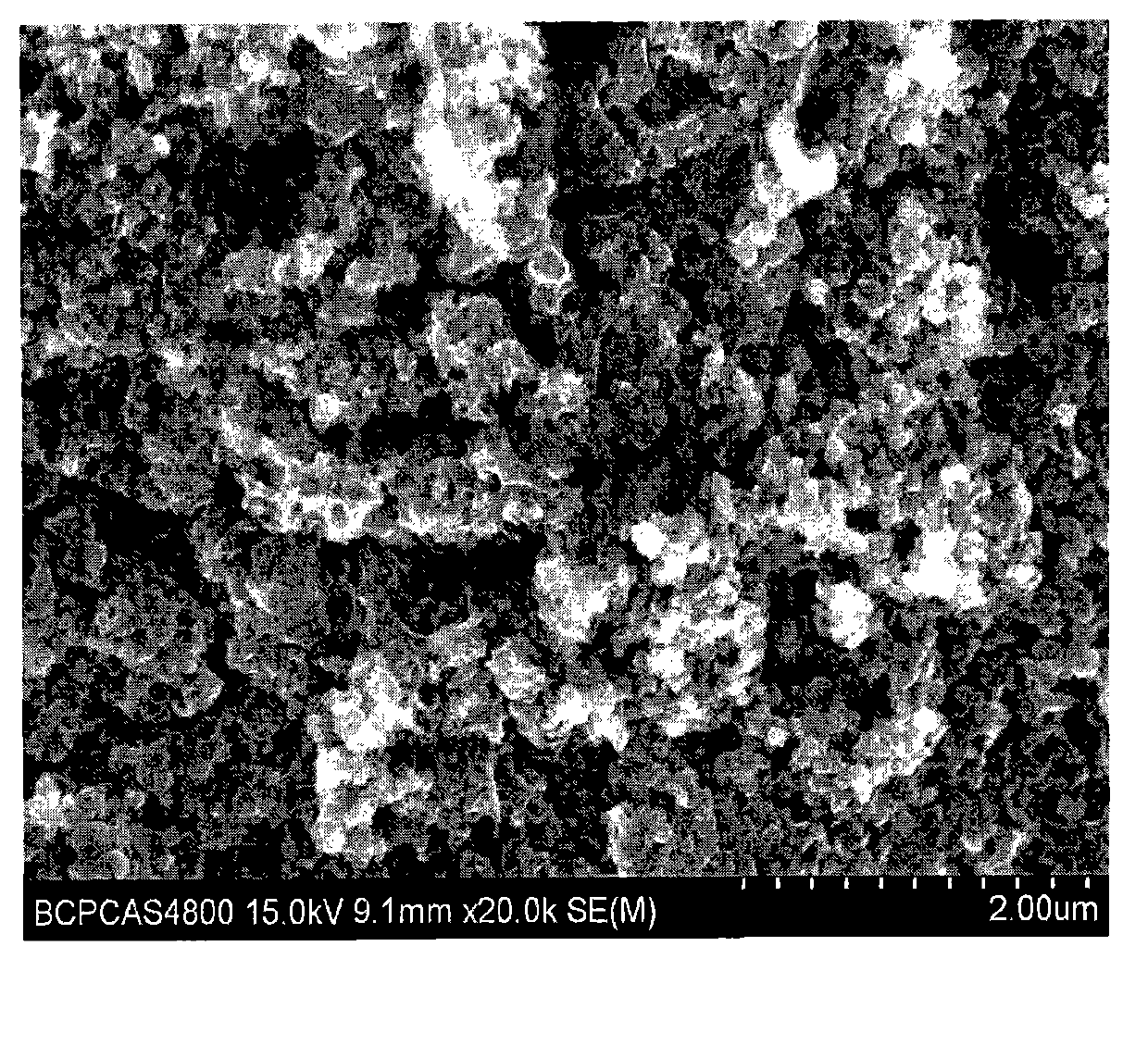

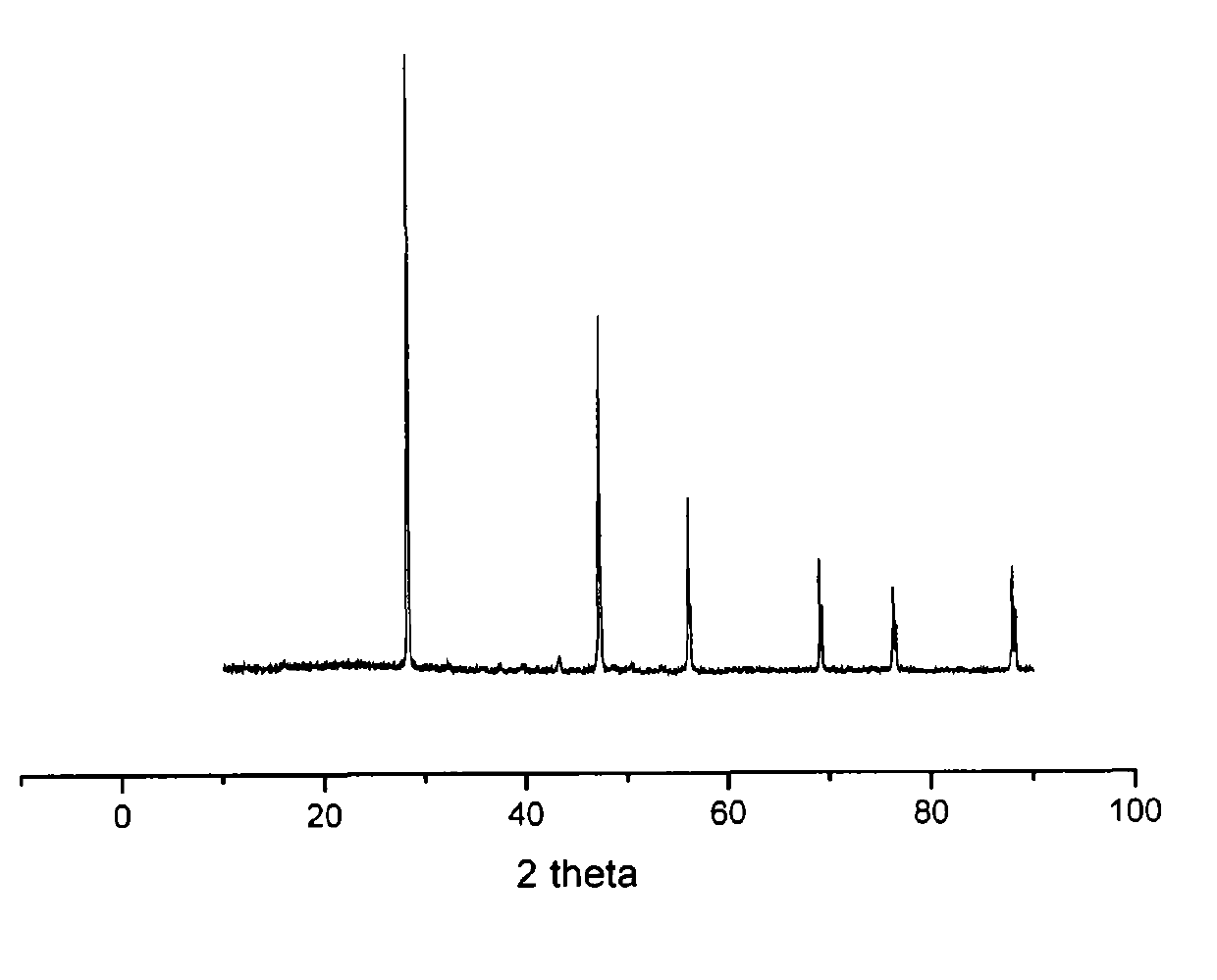

Embodiment 1

[0027] After the industrial silicon waste is pretreated and sorted by a 500-mesh sieve, the material is added to a 30% sucrose solution, and a stable suspension is obtained after thorough stirring. The suspension is spray-dried to obtain a sucrose-coated material. Then heat treatment at 700°C for 16 hours to obtain a silicon / copper / carbon composite material. Then mix it with acetylene black and polyvinylidene fluoride (PVDF) at a ratio of 8:1:1, add an appropriate amount of N-methylpyrrolidone (NMP), grind to a moderate viscosity, no graininess, and coat it on the copper foil. Bake in an oven at 50°C for 8 hours, and apply a pressure of 2 MPa with a hydraulic machine. Afterwards, they were dried in a vacuum oven at 120°C for 10 hours to form pole pieces and weighed. The thickness of the pole piece is 35~45μm. In the glove box, the lithium sheet is used as the negative electrode, the celgard2400 membrane is used as the diaphragm to assemble the battery, and the electrolyte is...

Embodiment 2

[0029] After the industrial silicon waste is pretreated and sorted by a 200-mesh sieve, the ball mill is milled at 100 rpm for 2 hours, 10% phenolic resin and appropriate amount of ethanol are added, fully stirred and spray-dried, and then heat treated at 800°C for 16 hours to obtain silicon / copper / carbon Composite materials. Then mix it with acetylene black and PVDF in a ratio of 8:1:1, add an appropriate amount of NMP, grind until the viscosity is moderate, without graininess, and coat it on the copper foil. Bake in an oven at 50°C for 8 hours, and apply a pressure of 2 MPa with a hydraulic machine. Afterwards, they were dried in a vacuum oven at 120°C for 10 hours to form pole pieces and weighed. The thickness of the pole piece is 35~45μm. In the glove box, the lithium sheet is used as the negative electrode, the celgard2400 membrane is used as the diaphragm to assemble the battery, the electrolyte is 1MLiPF 6 / EC+DMC. At 0.2mA / cm 2 Under charge and discharge, the reversi...

Embodiment 3

[0031] After the industrial silicon waste is pretreated and sorted by a 200-mesh sieve, 30% ascorbic acid is added, and after uniform grinding, it is heat-treated at 800° C. for 12 hours to obtain a silicon / copper / carbon composite material. Then mix it with acetylene black and PVDF at a ratio of 8:1:1, add an appropriate amount of NMP, grind until the viscosity is moderate, without graininess, and coat it on the copper foil. Bake in an oven at 50°C for 8 hours, and apply a pressure of 2 MPa with a hydraulic machine. Afterwards, they were dried in a vacuum oven at 120°C for 10 hours to form pole pieces and weighed. The thickness of the pole piece is 35~45μm. In the glove box, the lithium sheet is used as the negative electrode, the celgard2400 membrane is used as the diaphragm to assemble the battery, the electrolyte is 1MLiPF 6 / EC+DMC. At 0.2mA / cm 2 Under charge and discharge, the first reversible capacity of the material reaches 1600mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com